Main driving system of hybrid power locomotive

A main drive system and hybrid technology, applied in the field of transmission system, can solve the problems of small internal resistance of battery, influence on diesel speed, instability of main drive system, etc., to achieve the effect of improving stability and achieving precise and controllable effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

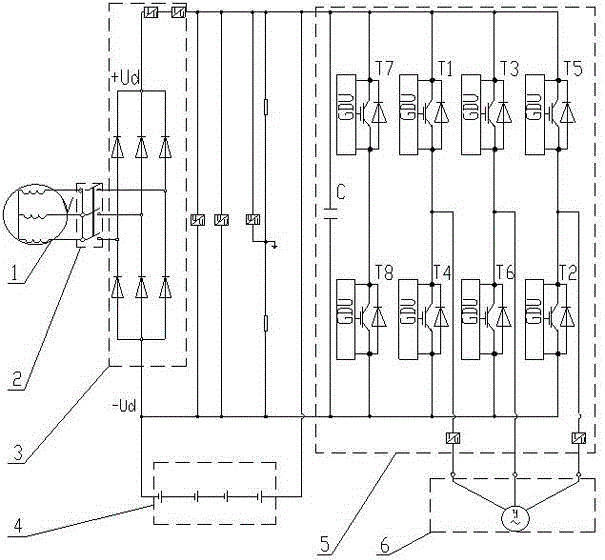

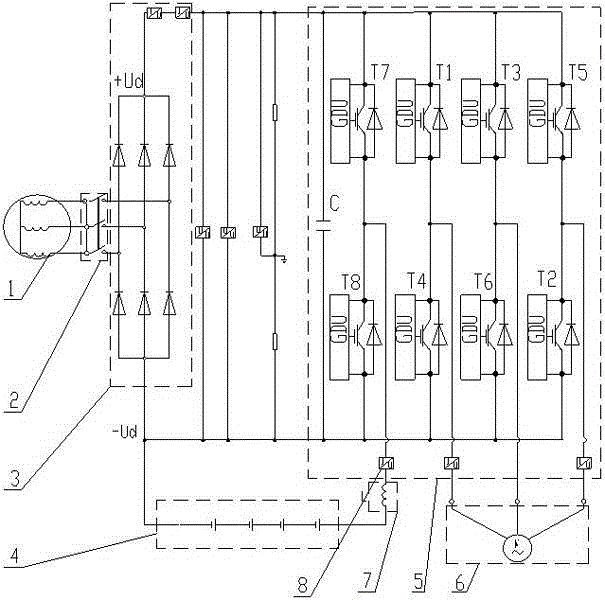

[0014] see figure 2 As shown, a hybrid locomotive main transmission system includes a main generator 1, a main contactor 2, a rectifier module 3, a power battery pack 4, an inverter module 5 and a traction motor 6, and the main generator 1 passes through the main contactor 2 is connected to the rectification module 3, and the rectification module 3 is connected to the inverter module 5, and the inverter module 5 includes a capacitor C and first to fourth modules, the first module includes modules T7 and T8 connected in series, and the second The module includes modules T1 and T4 connected in series, the third module includes modules T3 and T6 connected in series. The fourth module includes modules T5 and T2 connected in series, each module consists of transistors and diodes connected in parallel, capacitor C and the first The fourth to fourth mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com