roll making machine

A technology for making machines and reels, applied in the field of iron sheet packaging container manufacturing equipment, can solve the problems of collision and deformation of cylindrical iron sheet packaging barrels, falling off of iron sheet reels, uneven gluing, etc. The effect of improving training accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

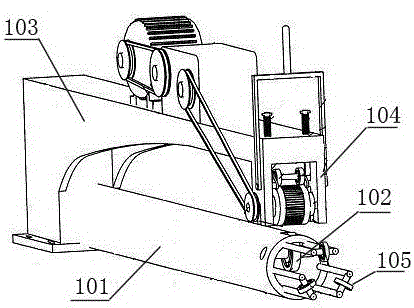

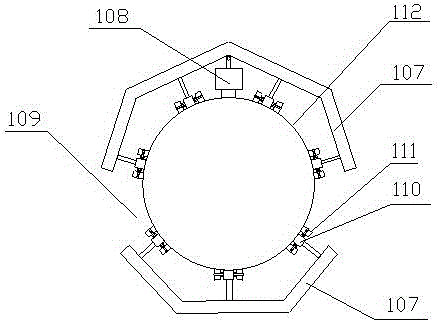

[0031] as attached figure 2 , 5 , 7, the present invention is a reel manufacturing machine, including reel shaping equipment for shaping the folded iron sheet, reel welding equipment for welding the reel interface after shaping, and reel transmission after welding The reel magnetic transmission device to the next process and the reel weld glue brushing device for applying glue to the welded reel seam. The reel sizing device includes a movable hook conveyor 108 and a sizing mechanism 109 connected to the first frame 107, the movable grapple conveyor 108 is above the sizing mechanism 109, and the sizing mechanism 109 includes 5-8 square / round steel 110 on 107. The main body of the movable claw hook conveyor 108 is cylindrical, with a connecting piece on the top, and holes on the connecting piece can be inserted into the sliding rod above the frame, so that the main body of the movable claw hook conveyor 108 can move along the sliding rod under pneumatic control. Moving forwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com