A laser vision guided welding robot fillet weld feature extraction method

A welding robot and vision-guided technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of inability to automatically determine the initial welding pose of the robot, difficult welding automation, etc., and achieve good practicability and characteristics. Extract full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the objectives, technical solutions and advantages of the present invention clearer, the following is a specific implementation process, and the present invention will be further described in detail with reference to the accompanying drawings.

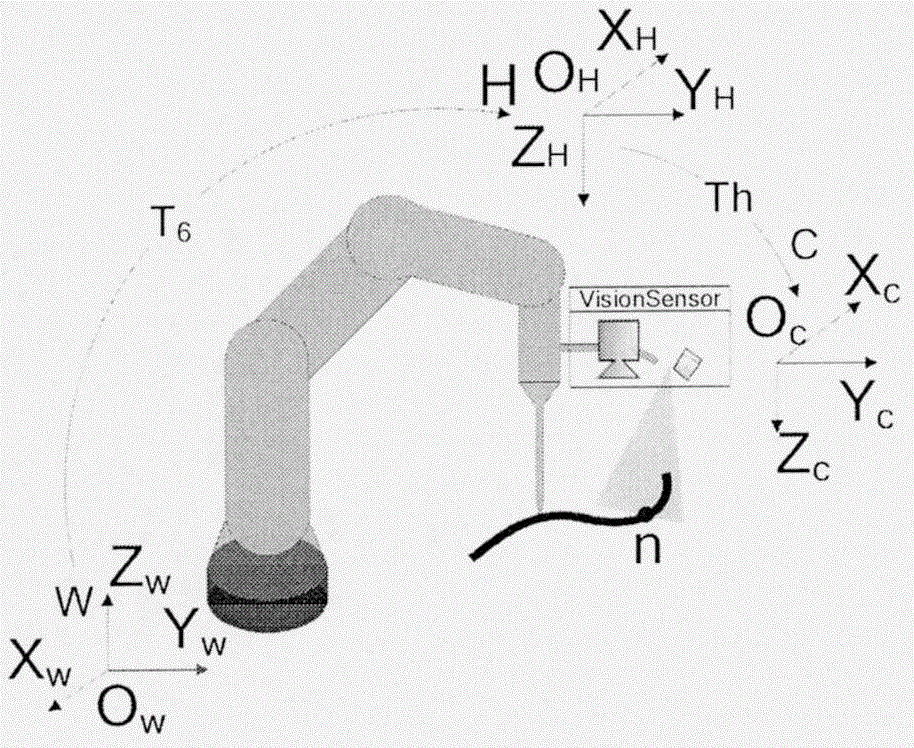

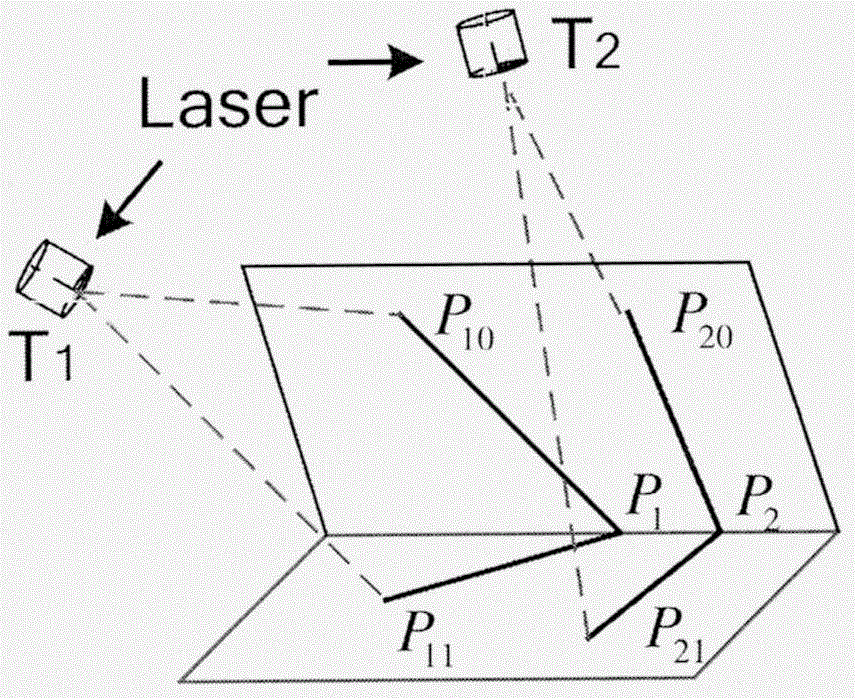

[0017] The basic idea of the present invention is: according to the practical application background of the laser vision-guided welding robot, combined with the actual welding characteristics of the fillet weld, the characteristics of the fillet weld are extracted. The fillet weld feature mainly includes two information quantities, the fillet angle and the weld point. In the corner angle determination part, the corner images with characteristic light bars in two poses are collected, the equations of the two planes are solved, and the angle between the two planes is determined. The schematic diagram is shown in the figure below. image 3 In the extraction part of the weld point, on the basis of intercepting the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com