Automatic magnetic element cleaning system

A technology of automatic cleaning and magnetic components, applied in the direction of cleaning methods using gas flow, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems of low cleaning efficiency, difficult to remove, toxicity and corrosion, etc., to achieve Good blowing effect, wide application range, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

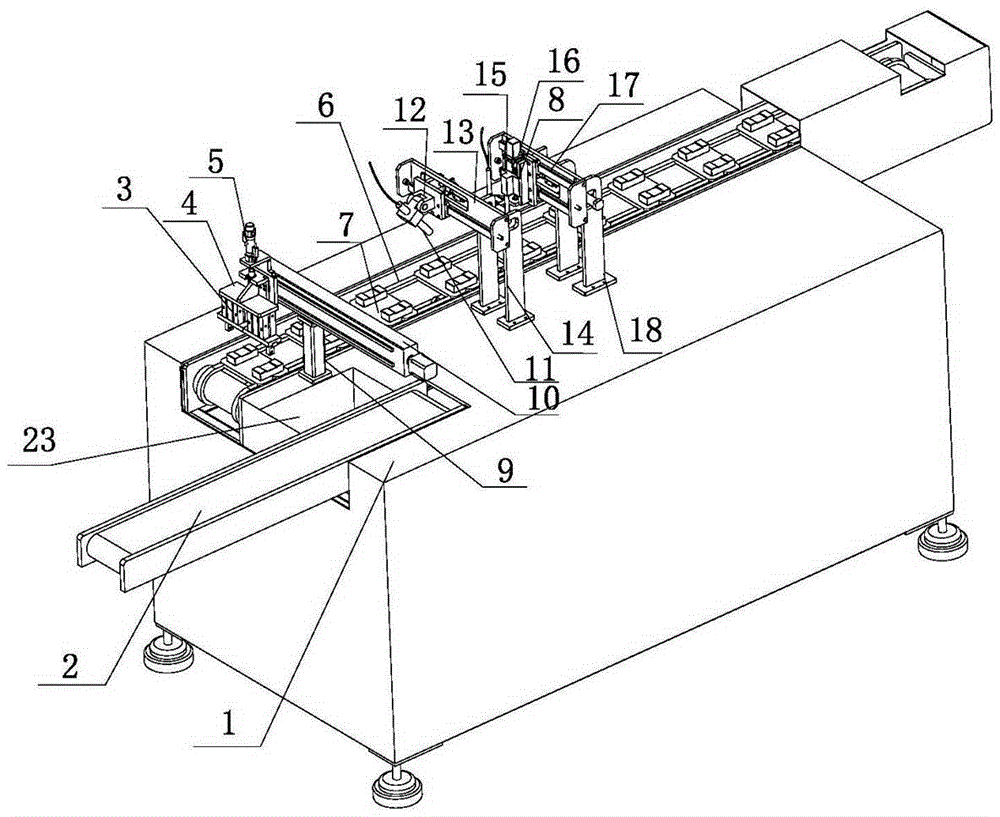

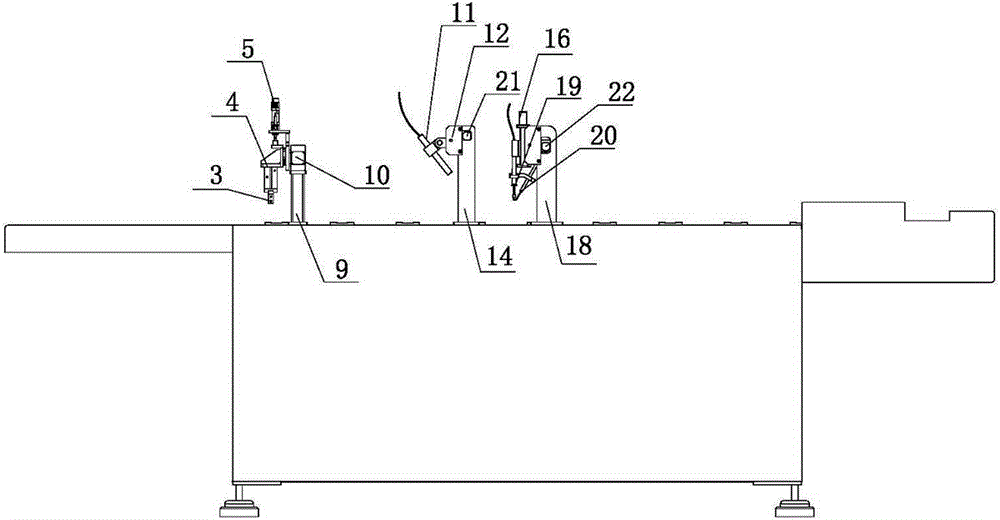

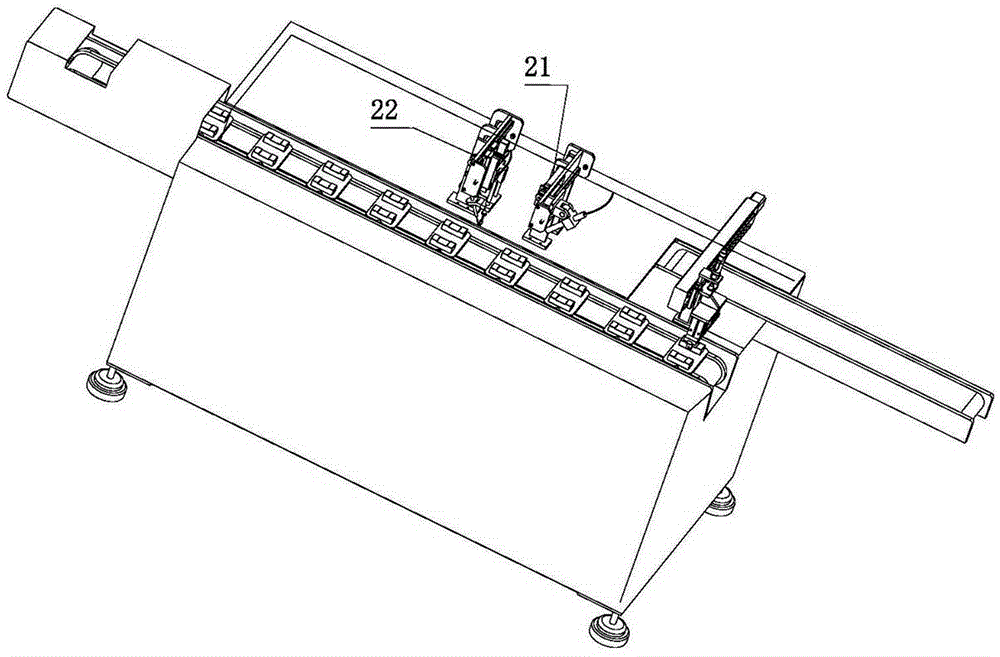

[0012] As shown in the drawings, an automatic cleaning system for magnetic components includes a control system, a workbench 1, a transmission mechanism controlled by the control system, a feeding manipulator assembly, an ultrasonic cleaning tank 23 sequentially arranged on the workbench 1, a blower Air mechanism, laser cleaning mechanism, the transmission mechanism includes the first conveyor belt 2 and the second conveyor belt 6 driven by the motor, the first conveyor belt 2 is placed at one end of the workbench 1, the The second conveyor belt 6 is arranged along the length direction of the table top of the workbench 1, and the ultrasonic cleaning tank 23 is arranged in parallel to the rear section of the first conveyor belt 2 and the second conveyor belt 6. Between the front section; the blowing mechanism includes a first bracket 14 installed on the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com