A dual-channel annular gas distribution device

A gas distribution device and a technology for gas distribution, applied in the direction of fractionation, etc., can solve the problems of long gas diffusion path, difficult gas uniform distribution, unfavorable installation and maintenance of the distributor, etc., so as to increase the degree of freedom of radial diffusion and simple structure. , the effect of convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

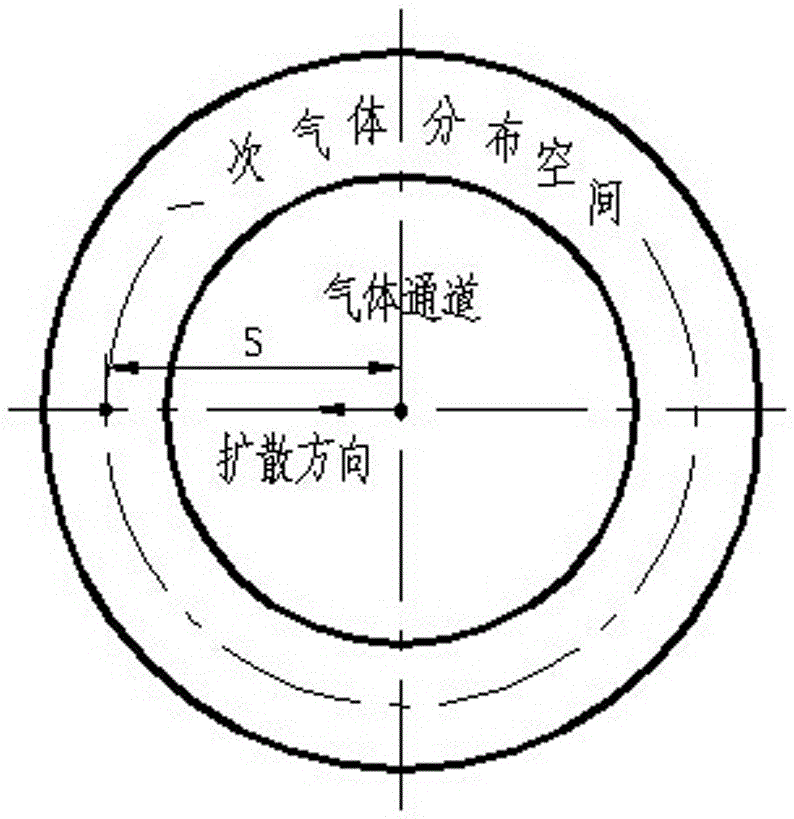

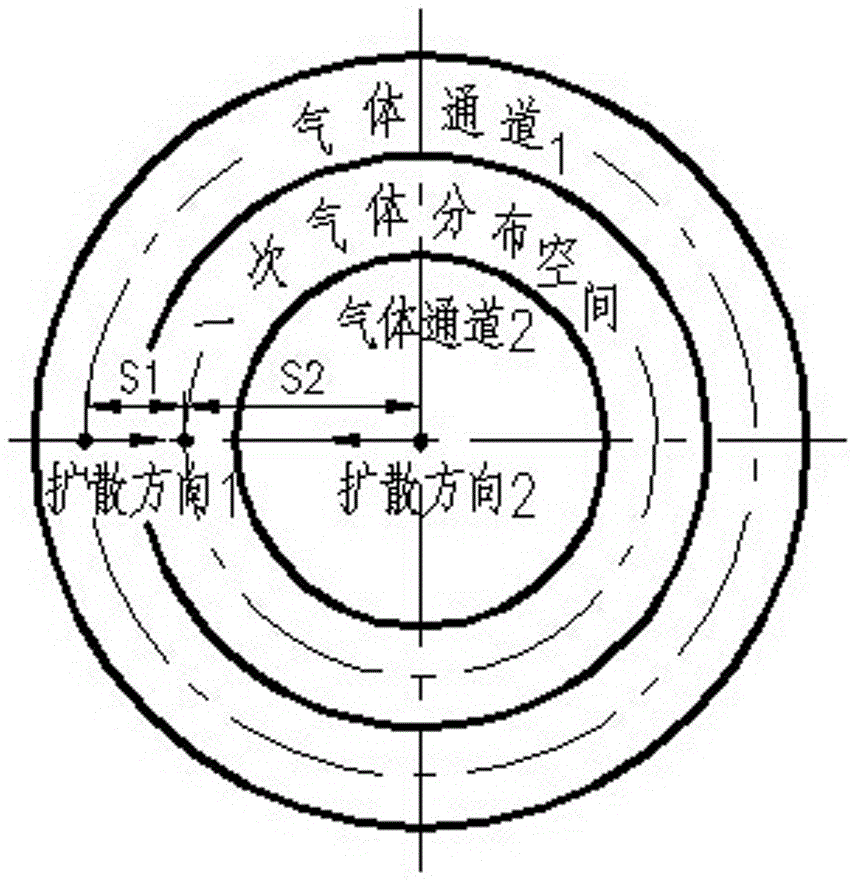

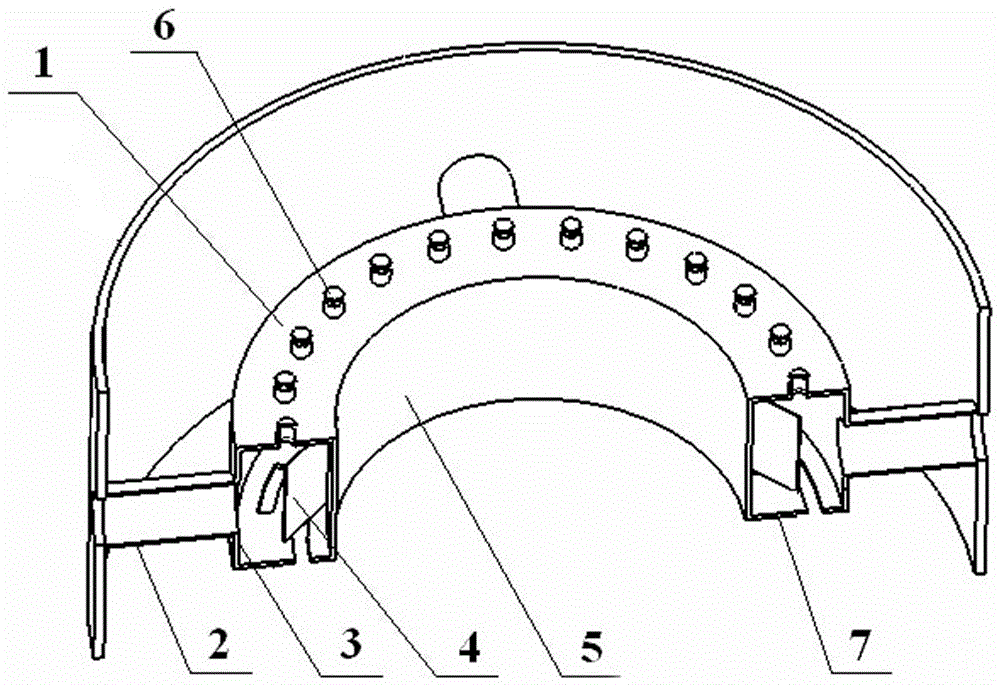

[0016] Below in conjunction with accompanying drawing, the present invention will be further described: figure 2 As shown, the present invention is a technical improvement to the existing gas distributor. It separates the primary distribution space of the distributor, thereby creating an annular gas channel 1 between the gas distributor and the inner wall of the tower, and the gas flows from the primary After the gas distribution space comes out, it is divided into two parts from gas channel 1 and gas channel 2 to reach the top of the distributor, and then each diffuses to the top of the primary gas distribution space of the distributor. At this time, the gas has two radial diffusion degrees of freedom: gas The degree of freedom of radial inward diffusion of channel 1 and the degree of freedom of radial outward diffusion of gas channel 2, the gas in each channel has a short diffusion path S1, S2, so that the gas can be quickly and effectively distributed in the top space of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com