Sound-wave-based square wood hole-defect recognition system and method

A defect identification and sound wave technology, which is applied in the direction of material analysis and detection response signal processing using sound wave emission technology, can solve the problems of high instrument cost, damage, inability to extract and select effective eigenvalue identification, etc., and achieve high recognition rate , easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

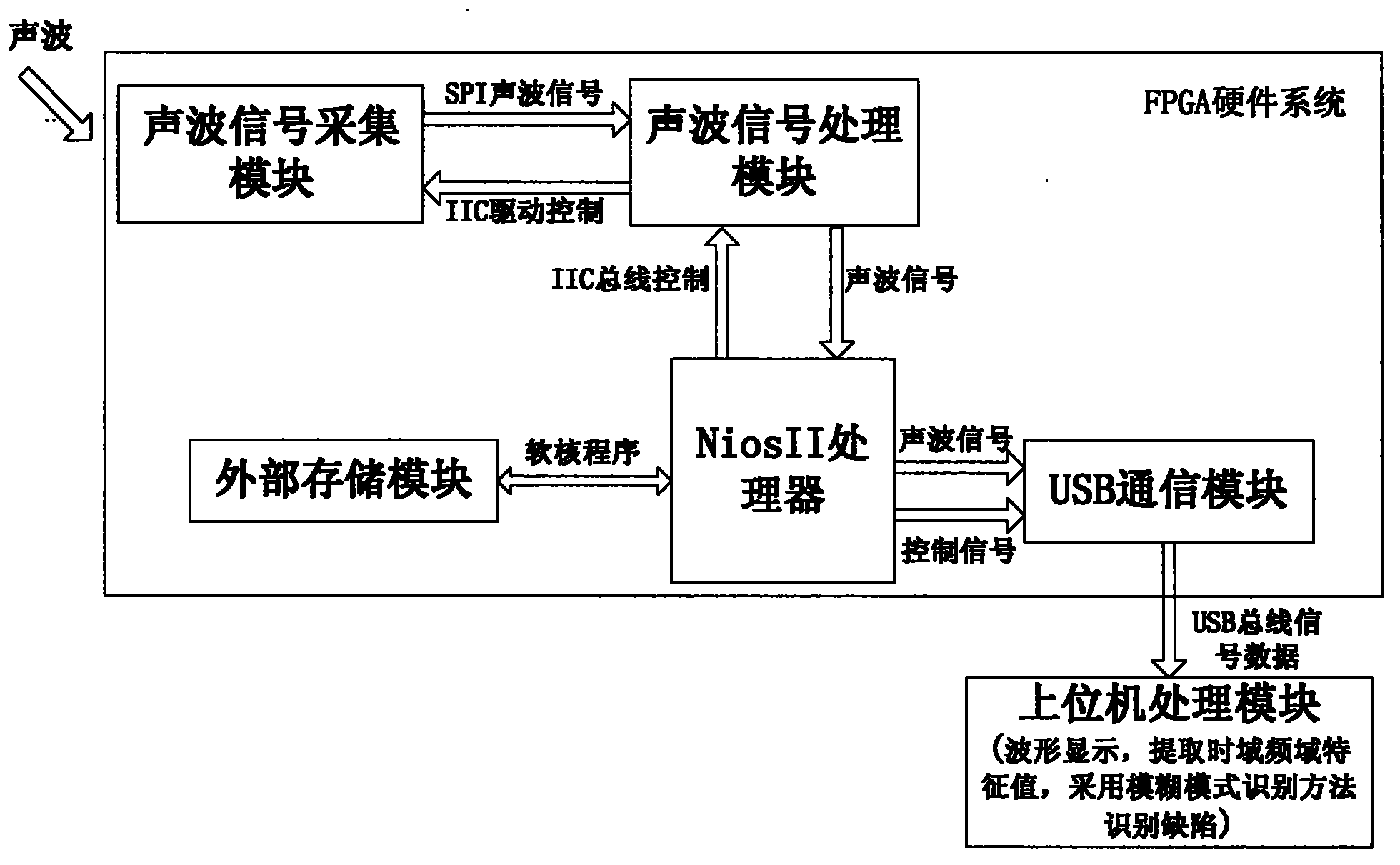

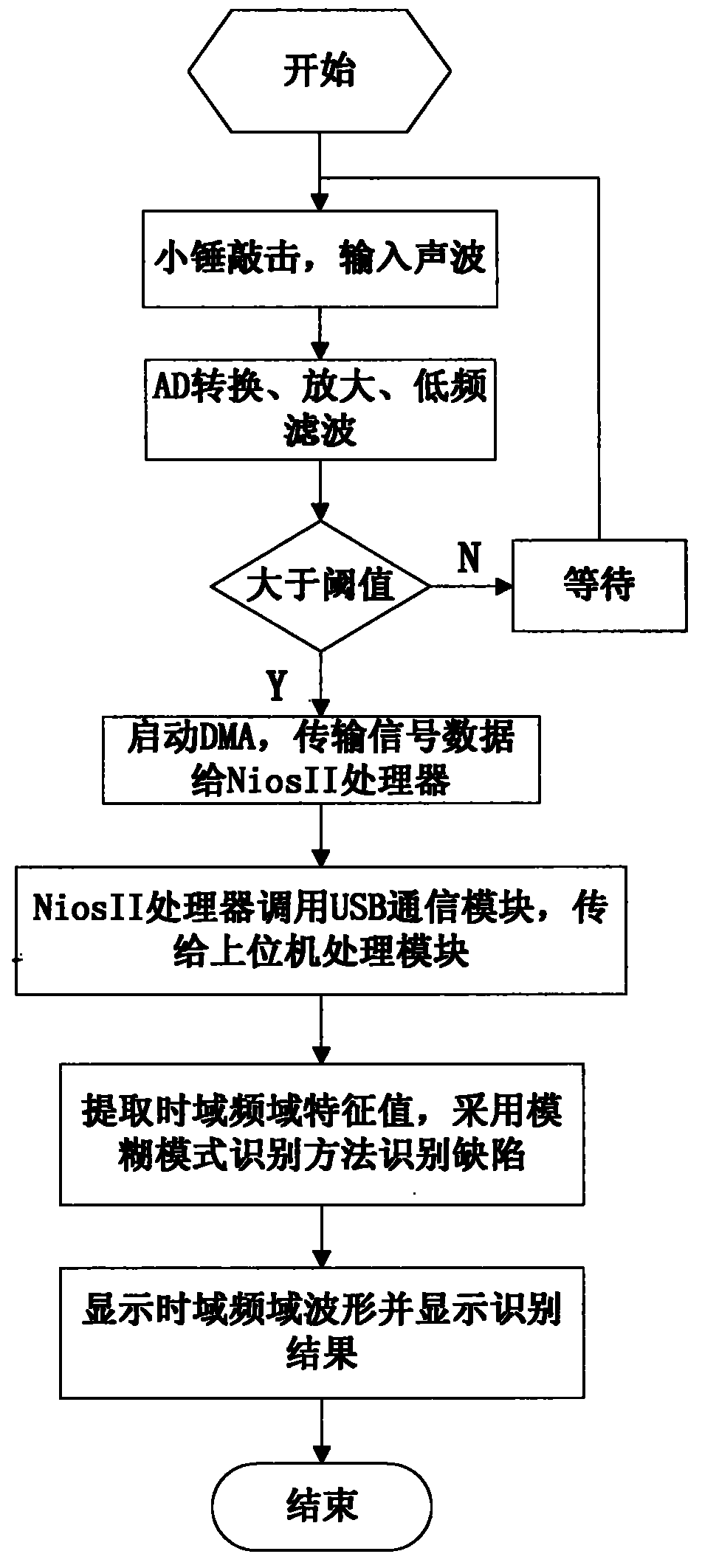

[0018] The invention provides a system and method for identifying square wood hole defects based on sound waves, the structure of which is as follows figure 1 As shown, it includes a small hammer, a sound wave signal acquisition module, a sound wave signal processing module, a NiosII processor, an external storage module, a USB communication module, and a host computer processing module.

[0019] The driver interface of the acoustic wave signal acquisition module adopts the IIC bus interface, and the data transmission adopts the SPI bus interface, which is used for the collection of acoustic wave analog signals, AD conversion, amplification and low-frequency filtering.

[0020] The sonic signal processing module is implemented in the FPGA chip and is bidirectionally connected with the sonic signal acquisition module. It is used to receive and buffer the sonic signal data. According to whether the collected sonic signal is greater than the threshold value, it is judged whether the ham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com