Generator set operating parameter measuring sensor fault diagnosis method and system

A technology for measuring sensors and operating parameters, applied in the direction of instruments, etc., can solve the problems of weak correlation and influence, and achieve the effect of increasing safety and reliability, preventing accidents, and reducing the cost of sensor fault diagnosis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be more fully described with reference to the accompanying drawings, in which some, but not all embodiments of the invention are shown. Indeed, the present invention can be embodied in many different forms, can monitor and diagnose many types of sensors, and should not be viewed as limited to the embodiments set forth herein; This disclosure is provided to satisfy applicable legal requirements. The substantive features of the present invention will be further described below in conjunction with the accompanying drawings and specific implementation methods.

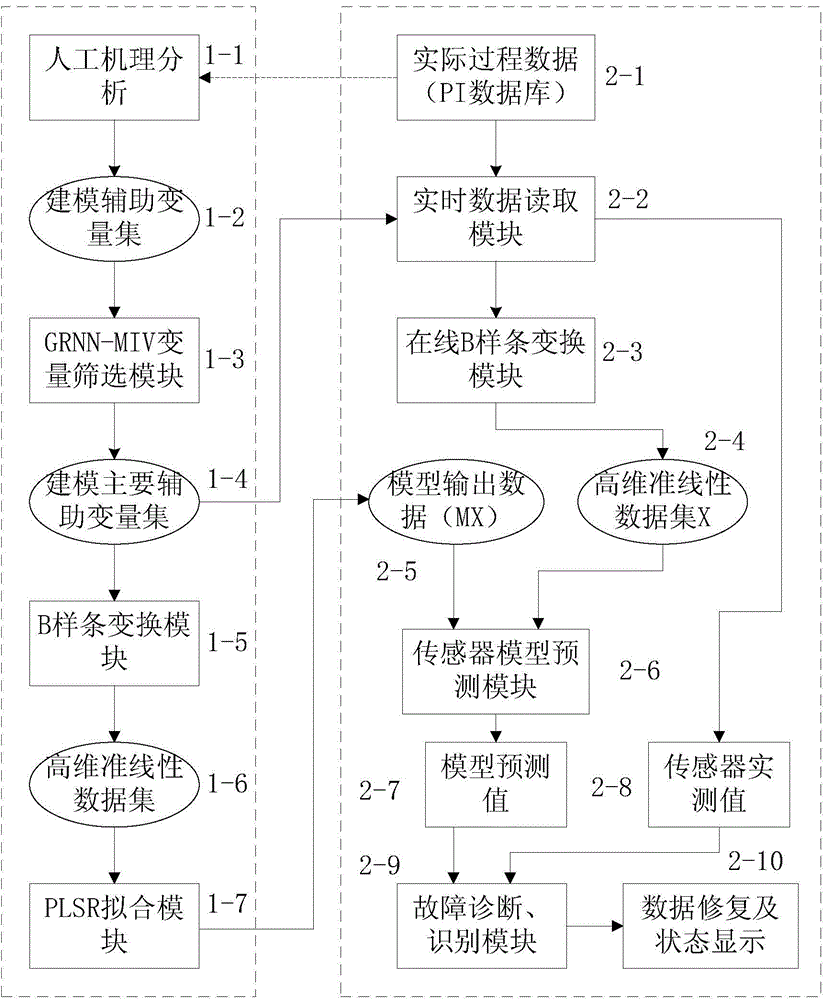

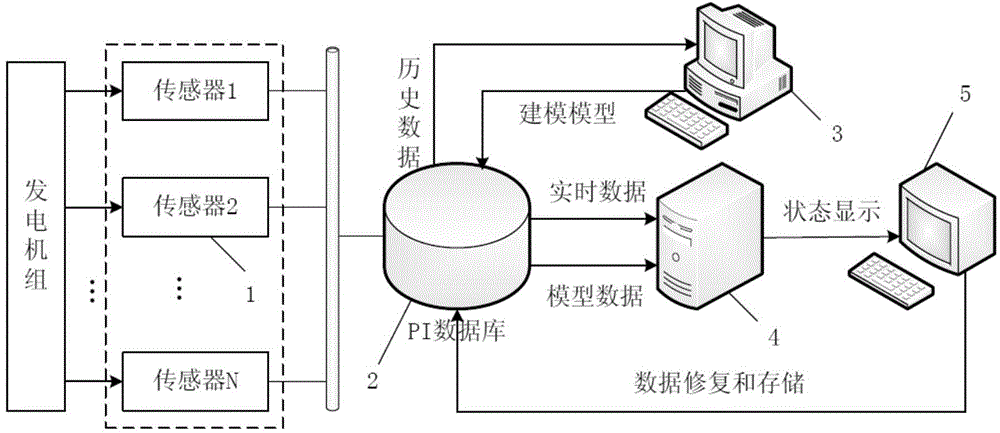

[0023] The realization of the fault diagnosis method of the generator set operating parameter measurement sensor is as follows: figure 1 shown.

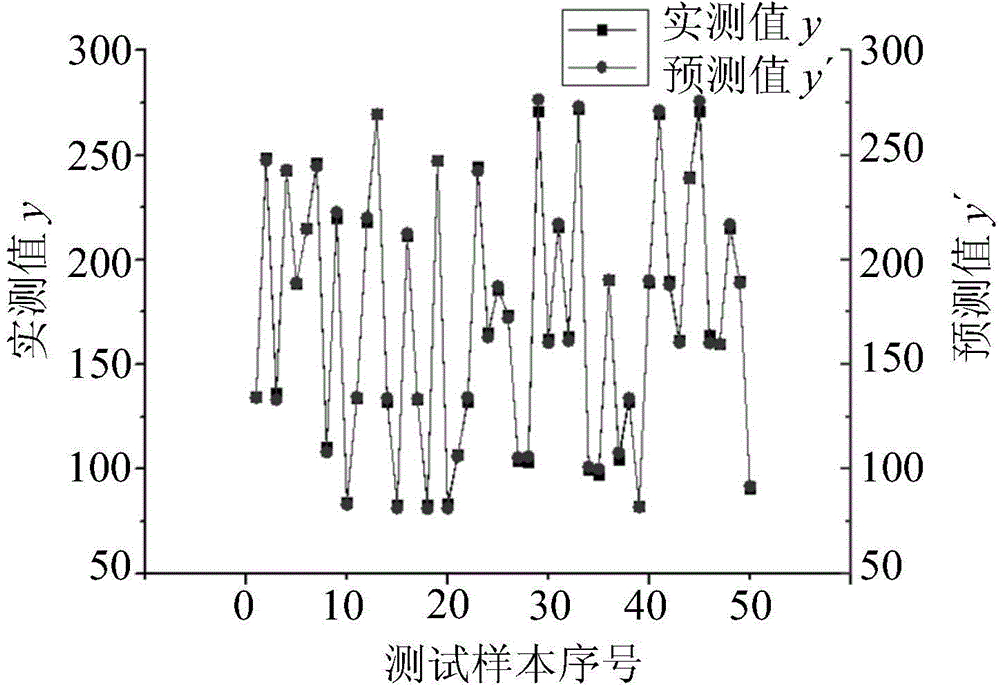

[0024] exist figure 1 , the left dotted box is the offline modeling flow chart, and the right is the online diagnosis flow chart. Artificial mechanism analysis 1-1 analyzes the historical data of the actual process, the purpose is to initiall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com