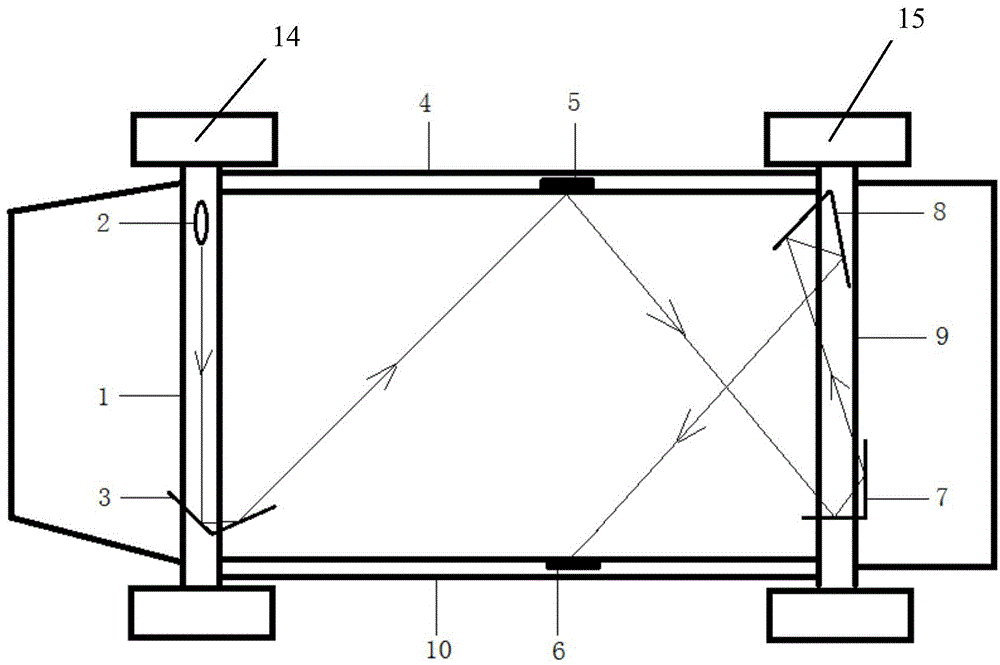

Car body deformation detector based on laser transmission

A detection device and vehicle body technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of limited accuracy, high cost, and limited accuracy, and achieve the effects of low detection cost, high directionality, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

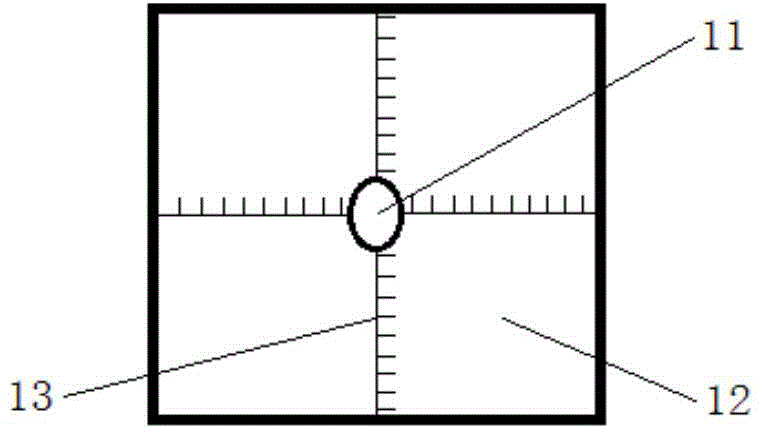

Examples

Embodiment 2

[0042] The difference between this embodiment and Embodiment 1 is that the laser is located at the lower end of the first metal reflector, the first side bridge is located at the lower end, the second side bridge is located at the upper end, and the third metal reflector is located at the fourth metal reflector the upper end. This embodiment is equivalent to the specular reflection structure relative to the horizontal line in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com