PVC artificial leather and its preparation method

A technology of artificial leather and temperature control, which is applied in the field of synthetic leather manufacturing, can solve the problem of insufficient thick hand feeling, achieve the effect of thick hand feeling, good physical properties, and increased folding resistance and scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

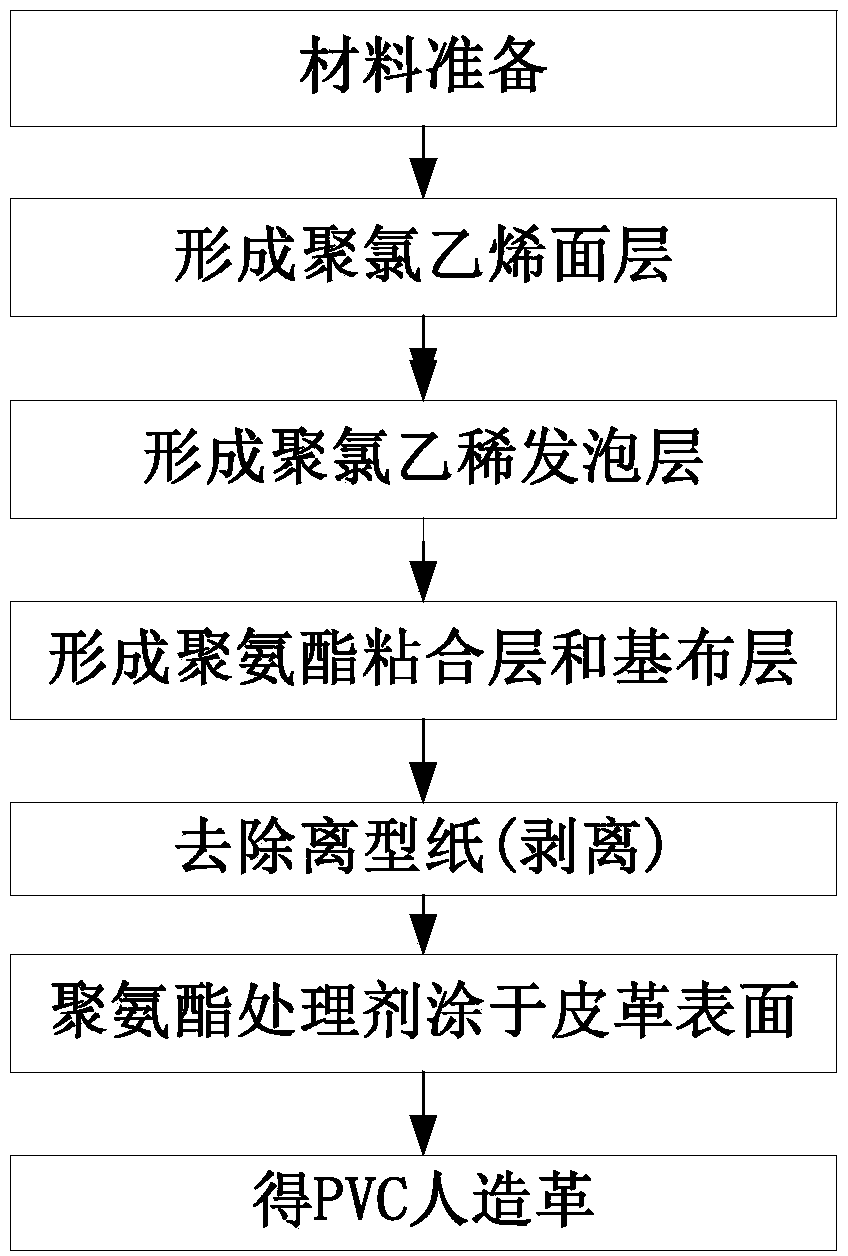

[0027] Please refer to figure 1 , a preparation method of PVC artificial leather, comprising the steps of:

[0028] Step 1, material preparation: polyvinyl chloride surface layer slurry; preparation of polyvinyl chloride foaming slurry; preparation of polyurethane adhesive; selection of base cloth and release paper;

[0029] The "preparation of polyvinyl chloride surface layer slurry" is specifically: the following raw materials in parts by weight: 100 parts of polyvinyl chloride resin, 60 parts of plasticizer, 1 part of stabilizer, 4 parts of PVC color paste, mixed and stirred for 30 Minutes, control the viscosity at 1500CPS, and prepare the PVC surface layer slurry;

[0030] The "preparation of polyvinyl chloride foam slurry" is specifically: the following raw materials in parts by weight: 100 parts of polyvinyl chloride resin (PSM), 70 parts of plasticizer (DOP), filler (CaCO 3 ) 60 parts, 3 parts of stabilizer (KZn), 3 parts of foaming agent (AC foaming powder), 4 parts ...

Embodiment 2

[0039] The present invention provides a kind of preparation method of PVC artificial leather, comprises the steps:

[0040] Step 1, material preparation: polyvinyl chloride surface layer slurry; preparation of polyvinyl chloride foaming slurry; preparation of polyurethane adhesive; selection of base cloth and release paper;

[0041] The "preparation of polyvinyl chloride surface layer slurry" is specifically: the following raw materials in parts by weight: 100 parts of polyvinyl chloride resin, 65 parts of plasticizer, 2 parts of stabilizer, 5 parts of PVC color paste, mixed and stirred for 35 Minutes, the viscosity is controlled at 2000CPS, and it is prepared into a polyvinyl chloride surface layer slurry;

[0042] The "preparation of polyvinyl chloride foam slurry" is specifically: the following raw materials in parts by weight: 100 parts of polyvinyl chloride resin, 80 parts of plasticizer, 70 parts of filler, 3 parts of stabilizer, and 3 parts of foaming agent , 5 parts o...

Embodiment 3

[0051] Step 1, material preparation: polyvinyl chloride surface layer slurry; preparation of polyvinyl chloride foaming slurry; preparation of polyurethane adhesive; selection of base cloth and release paper;

[0052] The "preparation of polyvinyl chloride surface layer slurry" is specifically: the following raw materials in parts by weight: 100 parts of polyvinyl chloride resin, 70 parts of plasticizer, 3 parts of stabilizer, 8 parts of PVC color paste, mixed and stirred for 40 Minutes, control the viscosity at 2500CPS, and prepare the PVC surface layer slurry;

[0053] The "preparation of polyvinyl chloride foam slurry" is specifically: the following raw materials in parts by weight: 100 parts of polyvinyl chloride resin, 90 parts of plasticizer, 80 parts of filler, 4 parts of stabilizer, and 4 parts of foaming agent , 8 parts of PVC color paste, stirred for 40 minutes, with a viscosity of 3000CPS, prepared into polyvinyl chloride foam slurry;

[0054] The "preparation of p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com