Sugar manufacturing technique for improving yield and reducing color value of white sugar

A technology for white sugar and color value, which is applied in the sugar production process of improving yield and reducing the color value of white sugar, and the field of alkaline sulfite method sugar production process. problems, to achieve the effect of improving the decolorization rate of clear juice, improving clarification efficiency, and improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

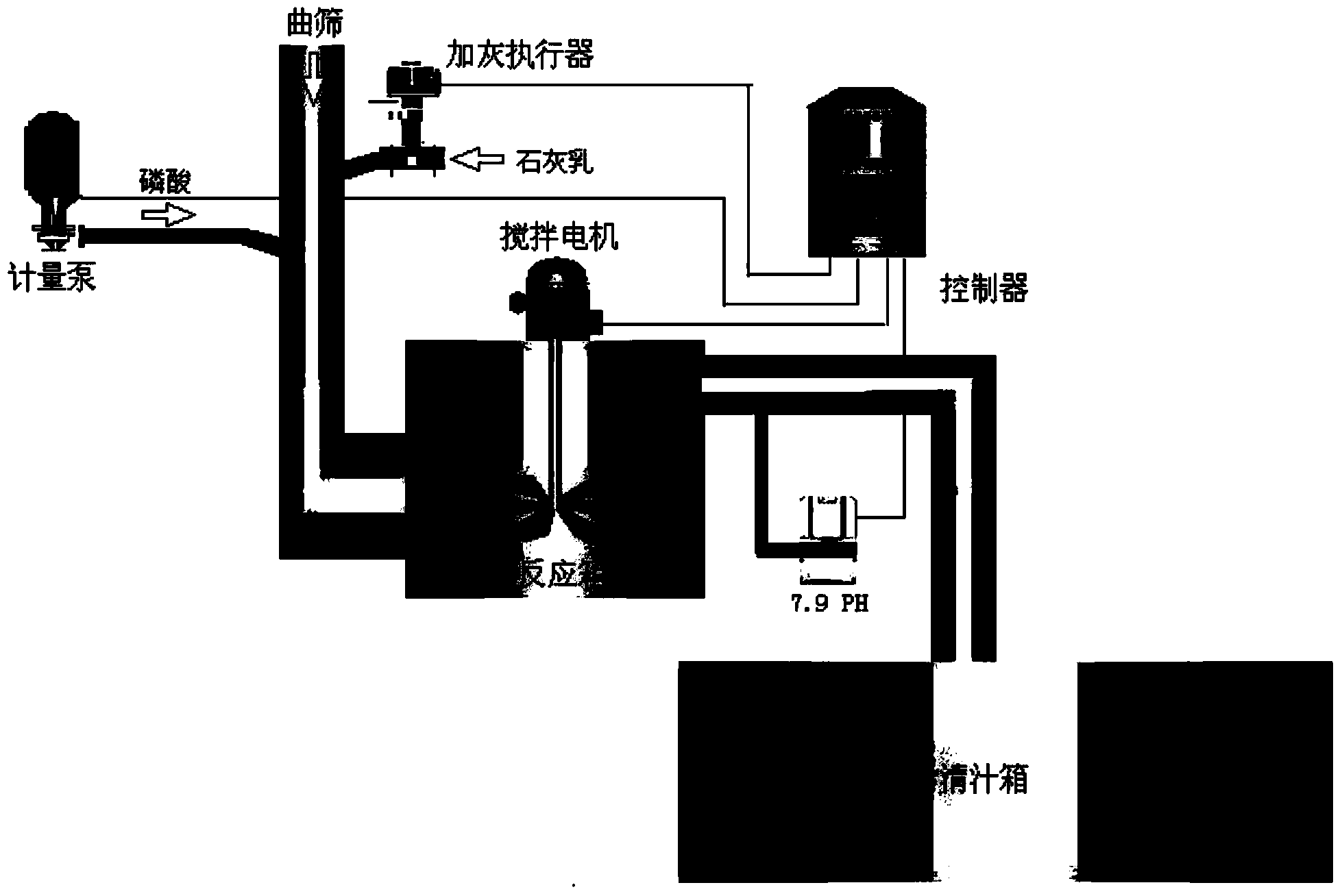

Method used

Image

Examples

preparation example Construction

[0066] The preparation method of neutralizing the juice is: sugarcane juice (brix 16-18BX °) is pumped into the sulfur fumigation neutralization reactor, and lime milk (6-8 °Bé) is added, and the sulfur fumigation intensity of each neutralization reaction depends on the specific it depends;

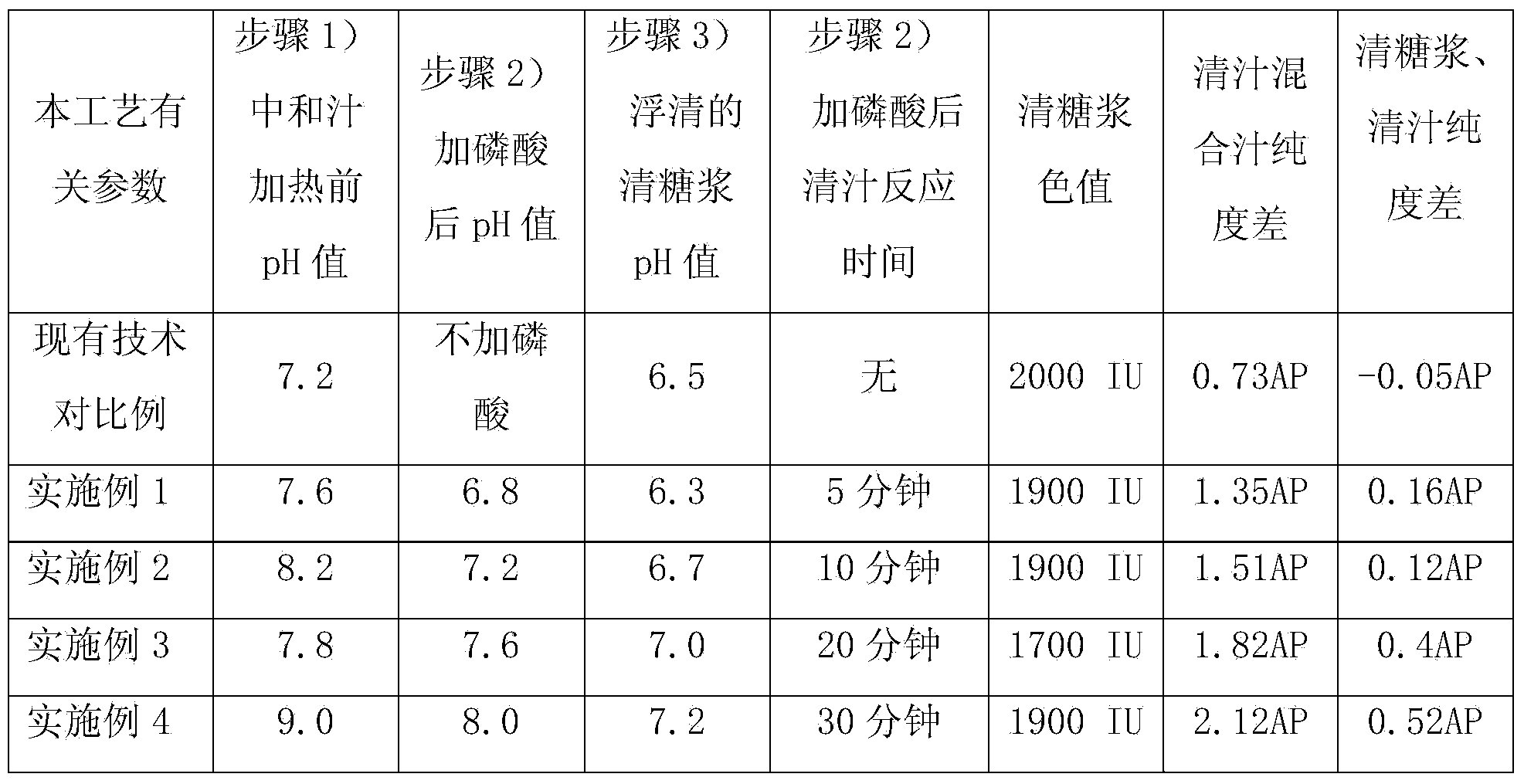

[0067] The color value of the clear syrup is measured by the method of GB317-2006 white sugar; the sample is dissolved in a pH (7.00±0.02) buffer solution, and after membrane filtration, the absorbance coefficient of the solution is measured at a wavelength of 420nm, and the value of the absorbance coefficient is multiplied by 1000. It is the color value of the International Committee for the Unification of Sugar Analysis (ICUMSA), and the result is defined as the ICUMSA unit (IU)

[0068] The purity of mixed juice, clear juice and clear syrup is determined by GB317-2006 white sugar polarimetric method. The measuring instruments include a sugar detector equipped with an adjustable analyze...

Embodiment 1

[0070] Explanation: In this example, the floating part of the syrup adopts the traditional process, and phosphoric acid and lime are also added, that is, there are two phosphoric acid addition points)

[0071] The sulfur smoke intensity of the neutralization reaction of sugarcane juice is controlled to 22-25cc, and the pH value of the neutralized juice is controlled to 7.6;

[0072] After the neutralized juice is heated to 95-98°C by the pump, it enters the settler for liquid-solid separation. The residence time of cane juice in the settler is 80-90 minutes;

[0073] The impurities are precipitated in the mud juice and sent to the suction filter for filtration. After the filtered juice is clarified, it forms mixed clear juice with the clear juice from the settler.

[0074] After the cane bran is filtered out through a curved sieve, it enters the phosphoric acid reaction system. Add phosphoric acid, the amount of phosphoric acid added is: the pH value of clear juice is reduc...

Embodiment 2

[0082] Explanation: the neutralization and clarification part of embodiment 2 is the same as embodiment 1, only specific parameters such as heating temperature, reaction time, pH value have change. The difference from Example 1 is that the pH value of the rough syrup drops lower, so only lime is added to the floating part of the syrup, and no phosphoric acid is added.

[0083] Cane juice (brix 16-18BX°) is pumped into the sulfur fumigation neutralization reactor, and lime milk (6-8°Bé) is added to control the sulfur fumigation intensity to 25-27cc, and the pH value of the neutralization juice to be 8.2, The pH value of the neutralized juice is controlled manually; the neutralized juice is pumped into the heater and heated to 98-102°C, and then enters the sedimentation system for liquid-solid separation. The residence time is controlled at 50-60 minutes, and the impurities are precipitated in the mud juice and sent to the suction filter for filtration. The mixed clear juice ham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com