One-step method for preparing cnts/fe nanocomposite

A technology of nanocomposite material and step method, which is applied in the field of preparing CNTs/Fe nanocomposite material, can solve the problems that the wave-absorbing performance is not greatly improved, and the preparation method is not very simple, etc., and achieves strong electromagnetic wave absorption ability, preparation method and The effect of simple materials and wide absorption frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Weigh 600 mg of multi-walled carbon nanotubes, put them into a 1000 ml four-necked flask, and add 600 ml of solvent kerosene. Fix the four-neck flask and place it in the electric heating jacket, and connect the spherical condenser, temperature controller, mechanical stirrer, and air inlet pipe respectively. Under the condition of a mechanical stirring speed of 320r / min, nitrogen gas was introduced for 60min to exhaust the air in the device.

[0032] (2) The iron pentacarbonyl liquid is volatile. Under the water bath temperature of 60°C, the iron pentacarbonyl vapor is introduced into the four-necked flask and dissolved in kerosene, and then the four-necked flask is slowly heated to 180°C with an electric heating mantle. Condensation reflux. Continue with N 2 As a guide gas, lead iron pentacarbonyl vapor to be dissolved in kerosene in a four-neck flask for thermal decomposition, N 2 The flow rate was kept at 100ml / min, and the reaction was continued for 4h.

[00...

Embodiment 2

[0035] (1) is the same as (1) of Embodiment 1.

[0036](2) Iron pentacarbonyl liquid is volatile. Under the water bath temperature of 60°C, iron pentacarbonyl vapor is introduced into a four-necked flask and dissolved in kerosene, and then the four-necked flask is slowly heated to 200°C with an electric heating mantle, and the Condensation reflux. Continue with N 2 As a guide gas, guide iron pentacarbonyl liquid vapor to dissolve in kerosene in a four-neck flask for thermal decomposition, N 2 The flow rate was kept at 100ml / min, and the reaction was continued for 4h.

[0037] (3) is the same as (3) of embodiment 1.

Embodiment 3

[0039] (1) is the same as (1) of Embodiment 1.

[0040] (2) Iron pentacarbonyl liquid is volatile. Under the water bath temperature of 60°C, iron pentacarbonyl vapor is introduced into a four-necked flask and dissolved in kerosene, and then the four-necked flask is slowly heated to 200°C with an electric heating mantle, and the Condensation reflux. Continue with N 2 As a guide gas, guide iron pentacarbonyl liquid vapor to dissolve in kerosene in a four-neck flask for thermal decomposition, N 2 The flow rate was kept at 100ml / min, and the reaction was continued for 14h.

[0041] (3) is the same as (3) of embodiment 1.

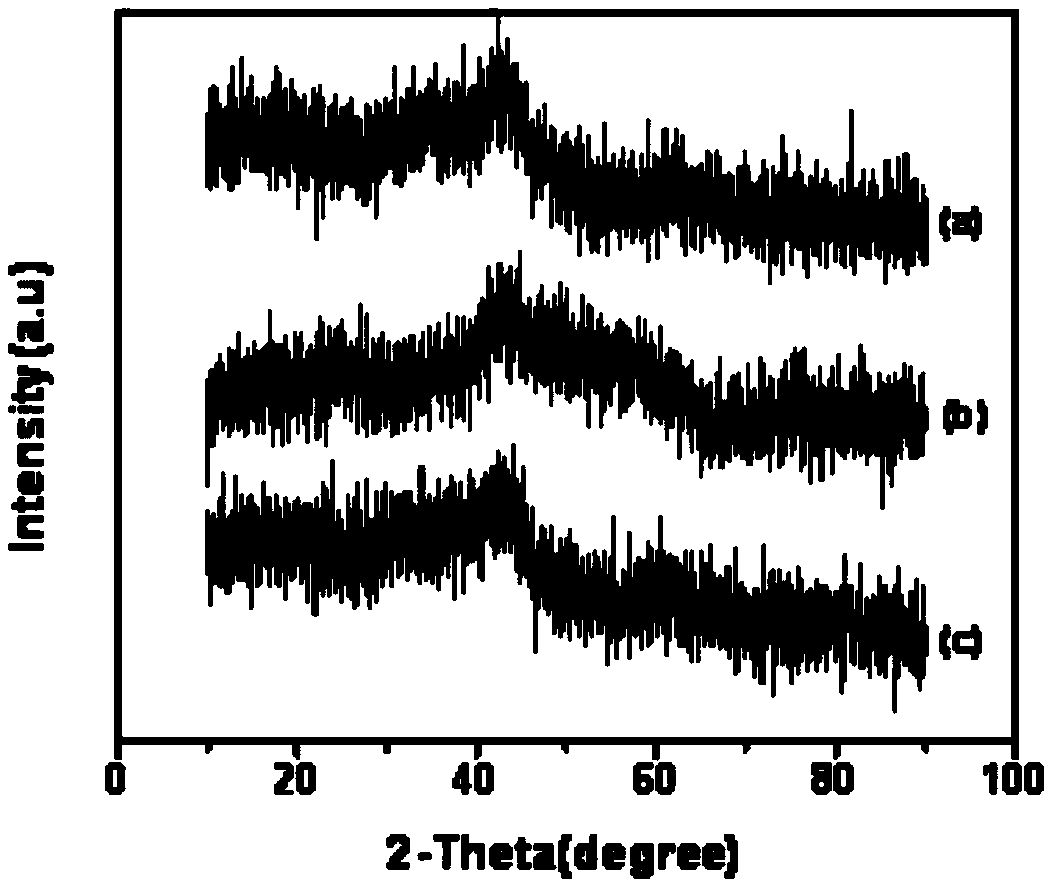

[0042] figure 1 For the X-ray diffraction pattern (embodiment 1,2,3) of the CNTs / Fe nanocomposite material prepared under different temperatures and time, we can find out from the XRD figure of composite material, the diffraction peak of Fe(110) crystal plane It is very obvious that there are no peaks of other impurities and oxides, confirming that the prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com