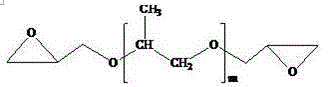

Preparation method of double-epoxy blocked polypropylene glycol

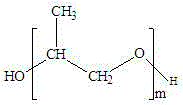

A polypropylene glycol and double epoxy group technology, applied in the chemical industry, can solve the problems of poor product color, too strong NaH basicity, troublesome solvent, etc., and achieve the effect of high end capping rate and light color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

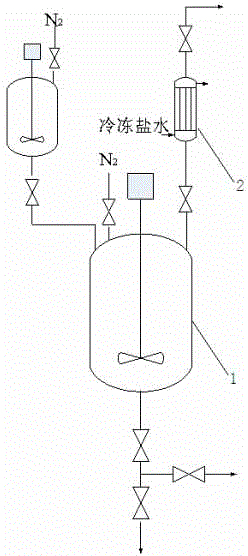

[0052] Put 112.9g (4.706moL) of NaH and 478.9g (5.176moL) of epichlorohydrin into the dripping reactor with nitrogen, stir for 30min and then fill with nitrogen to 0.4MPa; to the end-capped reactor with reflux condensation and stirring device Add 1000g (2.353moL) PPG-425, 0.782g (0.002353moL) tetra-n-butylammonium bromide, after vacuuming the nitrogen, open the nitrogen valve and the outlet valve of the reflux condensing device, and continue to pass nitrogen (nitrogen The end-capped kettle flows to the reflux condenser, and finally enters the tail gas device through the outlet valve); open the connection valve, and the dripping kettle presses the materials into the end-capped kettle for about 1h; after the dripping is completed, the temperature is raised to 40°C, at this temperature Reaction for 5h. After the reaction is completed, the temperature is lowered to 30°C, and a crude product is obtained; after the crude product is filtered and desalted, 50% phosphoric acid is added ...

Embodiment 2

[0055] Put 58.5g (2.439moL) of NaH and 234.7g (2.537moL) of epichlorohydrin into the nitrogen-filled dripping reactor, stir for 30min and then fill with nitrogen to 0.4MPa; to the end-capped reactor with reflux condensation and stirring device Add 1000g (0.976moL) PPG-1025, 0.808g (0.00488moL) tetraethylammonium chloride, after vacuuming the nitrogen, open the nitrogen valve and the outlet valve of the reflux condenser, and continue to pass nitrogen to the end-capped kettle (nitrogen is sealed The end kettle flows to the reflux condensing device, and finally enters the tail gas device through the outlet valve); open the connection valve, and the dripping kettle presses the material into the end kettle for about 1h; after the dripping is completed, the temperature is raised to 60°C and reacts at this temperature 8h. After the reaction is completed, the temperature is lowered to 30°C, and a crude product is obtained; after the crude product is filtered and desalted, 50% glacial a...

Embodiment 3

[0057] Put 35.6g (1.481moL) of NaH and 137.1g (1.481moL) of epichlorohydrin into the nitrogen-filled dropping reactor, stir for 30min and then fill with nitrogen to 0.4MPa; to the end-capped reactor with reflux condensation and stirring device Add 1000g (0.494moL) PPG-2025, 1.372g (0.00494moL) tetrabutylammonium chloride, after vacuuming nitrogen, open the nitrogen valve and the outlet valve of the reflux condenser, and continue to pass nitrogen to the capped kettle (nitrogen is sealed The end kettle flows to the reflux condensing device, and finally enters the tail gas device through the outlet valve); open the connection valve, and the dripping kettle presses the materials into the end kettle for about 1h; after the dripping is completed, the temperature is raised to 80°C and reacts at this temperature 10h. After the reaction is completed, the temperature is lowered to 30° C. to obtain a crude product; after the crude product is filtered to remove salt, 1% hydrochloric acid i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color | aaaaa | aaaaa |

| color | aaaaa | aaaaa |

| color | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com