Method of treating hexavalent chromium wastewater by immobilized microorganisms

A technology of immobilized microorganisms and hexavalent chromium, which is applied in the field of immobilized microorganisms to treat hexavalent chromium wastewater, can solve the problems of hexavalent chromium wastewater polluting the environment and affecting human health, and achieves strong poison resistance, good impact resistance, Simple effect of running equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Tested strain XJ-Ⅱ: the dominant strain isolated from saline-alkali land in Xinjiang, identified as Bacillus subtilis (Bacillus subtilis), the optimum growth temperature is 37°C.

[0049] This example is used to determine the effect of XJ-II on removing hexavalent chromium ions, and the specific operation is as follows.

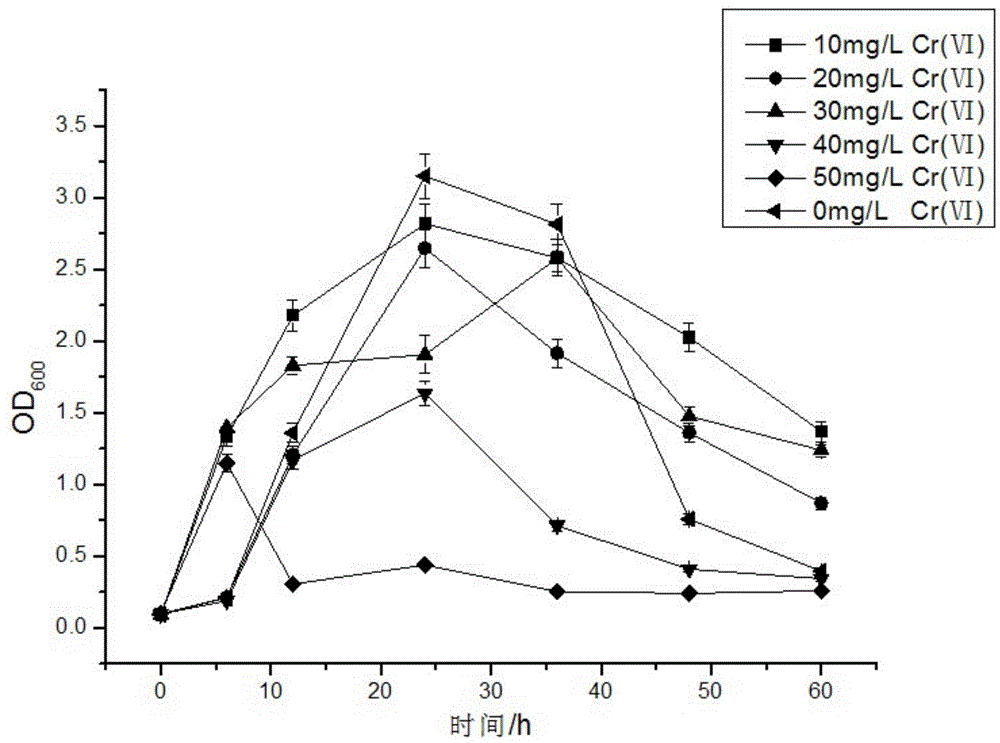

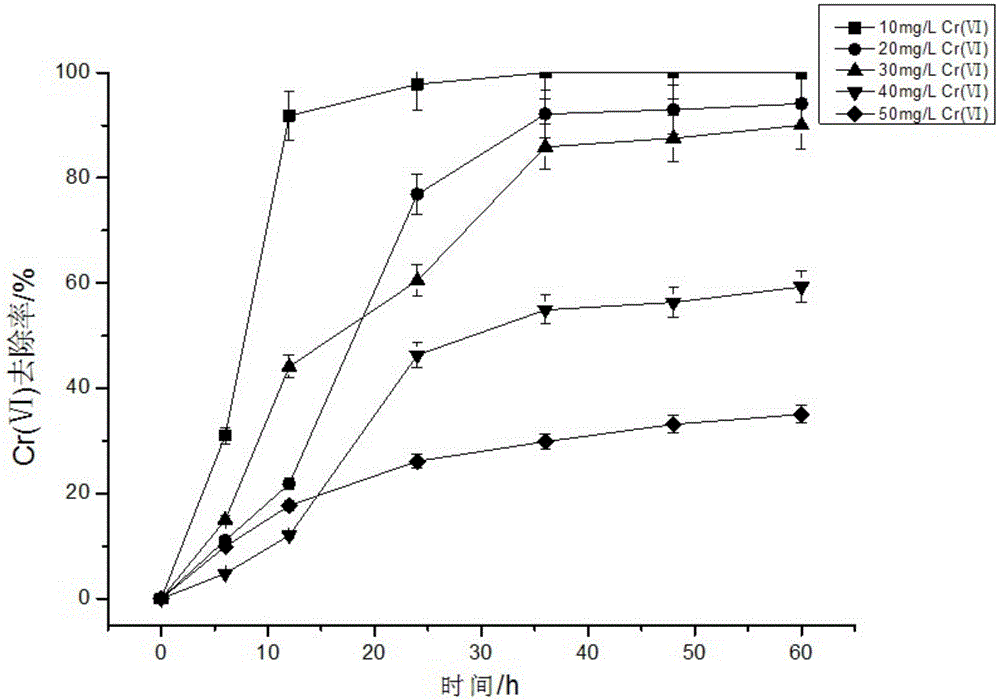

[0050] Take the slant strain XJ-Ⅱ, inoculate it in 100mL liquid medium, and culture it in a constant temperature shaking incubator at 37°C and 120r / min for 18h to obtain a seed solution. Take OD 600 =0.8 seed solution, inoculated in Cr(Ⅵ) solutions with different concentrations with 10% inoculum amount. Take out a certain amount of liquid at regular intervals within 60 hours, and measure the concentration OD of the bacterial solution 600 , each experiment was repeated three times, the same below, and the culture medium was used as the control. The supernatant was collected by centrifugation, and the residual Cr(VI) content in the solution was measur...

Embodiment 2

[0059] The influence of embodiment 2 additives on immobilized microorganism treatment Cr(Ⅵ)

[0060] 2.1 Experimental method

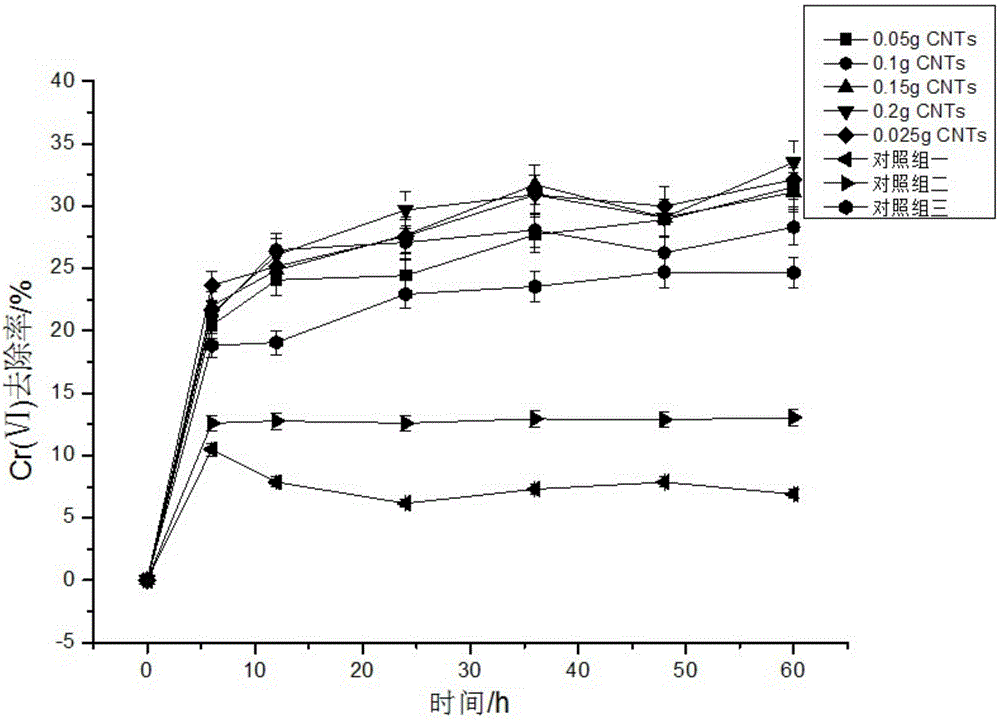

[0061] CNTs (carbon nanotubes), activated carbon and straw were used as additives to study the immobilization technology, and Cr(Ⅵ) solution was processed.

[0062] Take 100mL and incubate for 14h, OD 600 = 2.0 bacteria (XJ-II) precipitated after centrifugation, dissolved in 10mL SA solution with a final concentration of 1.5%, and then added 0.05g, 0.1g, 0.15g, 0.2g and 0.25g of a single additive, and stirred evenly Drop into 1% calcium chloride solution, take out after immobilization for 1 hour, wash with normal saline, and set aside.

[0063] The prepared immobilized microbial particles containing additives were added to 100mL of 10mg / L Cr(VI) solution, and the residual Cr(VI) content in the solution was measured at intervals within 60h. The immobilized granules without additives were used as control 1, the immobilized granules containing 0.25 g o...

Embodiment 3

[0089] The composition of the LB medium used in this example is as follows: yeast powder: 5g; peptone: 10g; NaCl: 10g; agar: 15g; distilled water: 1000mL. Adjust pH 7.2-7.4 with 10% HCl / NaCl. When preparing liquid medium, there is no need to add agar.

[0090] In this example, the preparation method of immobilized microbial particles is as follows: Take 100mL of culture for 14h, OD 600 =2.0 bacteria (XJ-Ⅱ) precipitated after centrifugation, dissolved in 10mL SA solution with a final concentration of 1.5%, then added 0.25g of CNTs, stirred evenly, dropped into 1% calcium chloride solution, immobilized for 1h Then take it out, wash it with normal saline, and set it aside.

[0091] Add 20%, 40%, 60%, 80%, and 100% LB medium to 10 mg / L Cr(Ⅵ) solution, treat 100 mL of the above solution with immobilized microbial particles, and investigate the effect of the amount of medium on the immobilized microorganism. Effect of particle treatment on Cr(VI). Wherein, in the 10mg / L Cr(Ⅵ) so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com