Preparation method of molybdenum and antimony co-doped titanium-based tin dioxide electrocatalytic electrode

A technology of tin dioxide and co-doping, which is applied in the direction of electrodes, electrolytic processes, electrolytic components, etc., can solve the problems of high price, and achieve the effect of thorough treatment, simple and controllable preparation method, and easy large-scale electrode preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

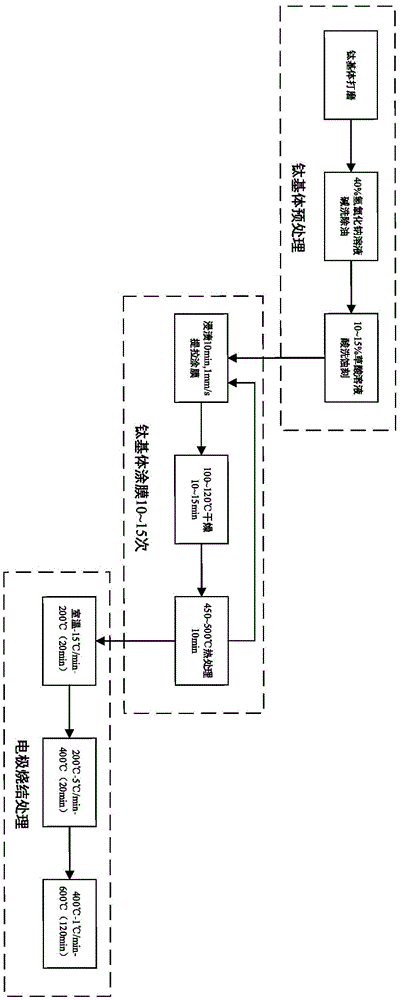

[0033] (2) Preparation of sol: using ethanol as the solvent, the atomic molar ratio of Sn, Sb, and Mo is 100:3:1~3, and the source of the above elements is SnCl 4 ·5H 2 O, Sb 2 o 3 , (NH 4 ) 6 Mo 7 o 24 and other raw materials, add complexing agent citric acid and ethylene glycol, wherein the molar ratio of metal ion, citric acid and ethylene glycol is 1:3:3; metal ion refers to the sum of Sn, Sb, Mo ions. After the raw materials are completely dissolved, fully stir in a 60°C water bath for 1 hour, and then stand and age in a 60°C water bath for 2 hours.

[0034] (3) Coating preparation: Take out the above-mentioned treated titanium electrode substrate, blot the moisture attached to the surface of the substrate, and then pull the coating film with an immersion pulling machine; the titanium substrate is immersed in the sol for 10 minutes, at a rate of 1mm / min Pull out the sol; after each film coating, dry in a blast drying oven at a drying temperature of 100-120°C and a ...

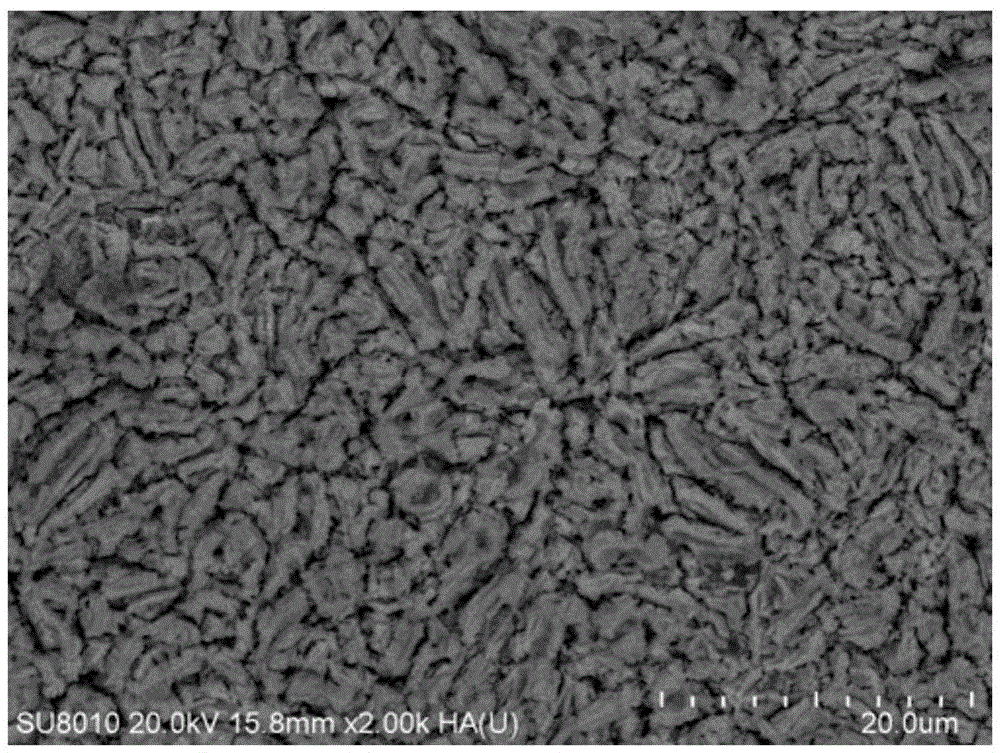

Embodiment 1

[0041] (2) Preparation of sol: use ethanol as the solvent, the atomic molar ratio of Sn, Sb, and Mo is 100:3:1, and the source of the above elements is SnCl 4 ·5H 2 O, Sb 2 o 3 , (NH 4 ) 6 Mo 7 o 24 and other raw materials, adding complexing agent citric acid and ethylene glycol, wherein the molar ratio of metal ions, citric acid and ethylene glycol is 1:3:3. After the raw materials are completely dissolved, fully stir in a 60°C water bath for 1 hour, and then stand and age in a 60°C water bath for 2 hours.

[0042] (3) Coating preparation: Take out the above-mentioned treated titanium electrode substrate, blot the moisture attached to the surface of the substrate, and then pull the coating film with an immersion pulling machine; the titanium substrate is immersed in the sol for 10 minutes, at a rate of 1mm / min Pull out the sol; after each film coating, dry in a blast drying oven at a drying temperature of 100°C and a drying time of 15 minutes; after drying, cool at roo...

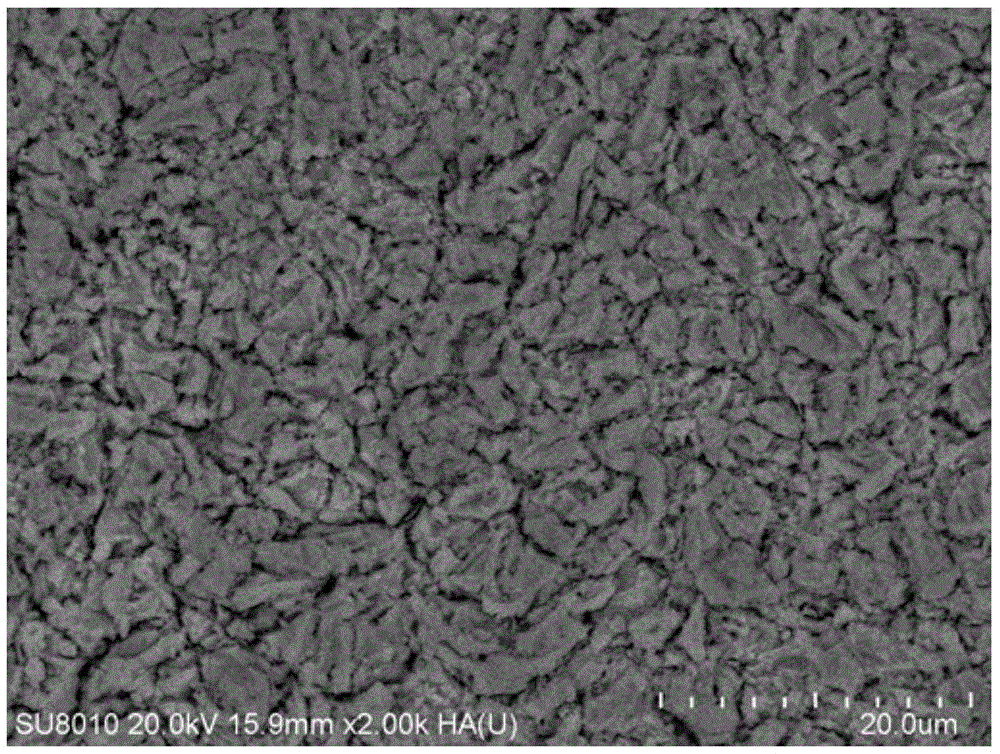

Embodiment 2

[0047] (2) Preparation of sol: use ethanol as the solvent, the atomic molar ratio of Sn, Sb, and Mo is 100:3:2, and the source of the above elements is SnCl 4 ·5H 2 O, Sb 2 o 3 , (NH 4 ) 6 Mo 7 o 24 and other raw materials, adding complexing agent citric acid and ethylene glycol, wherein the molar ratio of metal ions, citric acid and ethylene glycol is 1:3:3. After the raw materials are completely dissolved, fully stir in a 60°C water bath for 1 hour, and then stand and age in a 60°C water bath for 2 hours.

[0048] (3) Coating preparation: Take out the above-mentioned treated titanium electrode substrate, blot the moisture attached to the surface of the substrate, and then pull the coating film with an immersion pulling machine; the titanium substrate is immersed in the sol for 10 minutes, at a rate of 1mm / min Pull out the sol; dry it in a blast drying oven after each film coating, the drying temperature is 120 °C, and the drying time is 10 min; after drying, it is coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com