Preparation method for carbon fiber reinforced polyimide resin composite material

A technology of polyimide resin and composite materials, which is applied in the direction of coating, etc., can solve the problems of composite materials such as poor strength, rigidity and high temperature resistance, limited application fields, complicated preparation process, etc., and achieve good surface quality and excellent preparation process. Simple, good heat resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

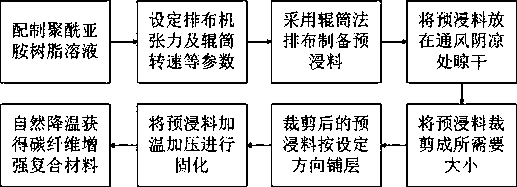

[0029] The carbon fiber reinforced polyimide resin composite material preparation process of the present invention is as follows:

[0030] The first step: preparing a polyimide resin solution, the solvent is ethanol, and the solid content of the polyimide resin in the solution is 50%;

[0031] The second step: set the parameters of the roller layout machine, the roller speed is 12m / min, the tension is 5N, use the polyimide resin solution prepared in the first step and the strength is T700 level, the tow is 12K Carbon fiber, carbon fiber reinforced polyimide resin prepreg is prepared by roller arrangement method;

[0032] Step 3: Put the carbon fiber reinforced polyimide resin prepreg obtained after the arrangement into an environment with a temperature of 27°C and a humidity below 40% to dry naturally to obtain a carbon fiber reinforced polyimide resin prepreg finished product;

[0033] The fourth step: cutting the carbon fiber reinforced polyimide resin prepreg obtained in ...

Embodiment 2

[0037] The carbon fiber reinforced polyimide resin composite material preparation process of the present invention is as follows:

[0038] The first step: preparing a polyimide resin solution, the solvent is ethanol, and the solid content of the polyimide resin in the solution is 30%;

[0039] The second step: set the parameters of the roller layout machine, the roller speed is 26m / min, the tension is 7N, use the polyimide resin solution prepared in the first step and the strength is T300 level, tow 6K Carbon fiber, arranged by roller method to prepare carbon fiber reinforced polyimide resin prepreg;

[0040] Step 3: Put the carbon fiber reinforced polyimide resin prepreg obtained after the arrangement into an environment with a temperature of 10°C and a humidity below 40% to dry naturally to obtain a carbon fiber reinforced polyimide resin prepreg finished product;

[0041] The fourth step: cutting the carbon fiber reinforced polyimide resin prepreg obtained in the third st...

Embodiment 3

[0045] The carbon fiber reinforced polyimide resin composite material preparation process of the present invention is as follows:

[0046] The first step: preparing a polyimide resin solution, the solvent is ethanol, and the solid content of the polyimide resin in the solution is 40%;

[0047] The second step: set the parameters of the roller layout machine, the roller speed is 30m / min, the tension is 5N, use the polyimide resin solution prepared in the first step and the strength is T800 level, the tow 3K Carbon fiber, arranged by roller method to prepare carbon fiber reinforced polyimide resin prepreg;

[0048] Step 3: Put the carbon fiber reinforced polyimide resin prepreg obtained after the arrangement into an environment with a temperature of 30°C and a humidity below 40% to dry naturally to obtain a carbon fiber reinforced polyimide resin prepreg finished product;

[0049] The fourth step: cutting the carbon fiber reinforced polyimide resin prepreg obtained in the thir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com