Feeding car for sawing machine

A technology for feeding trolleys and sawing machines, which is applied to the attachments of sawing machines, metal sawing equipment, clamping, etc., and can solve problems such as low efficiency in loading and unloading bars and difficulty in height adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

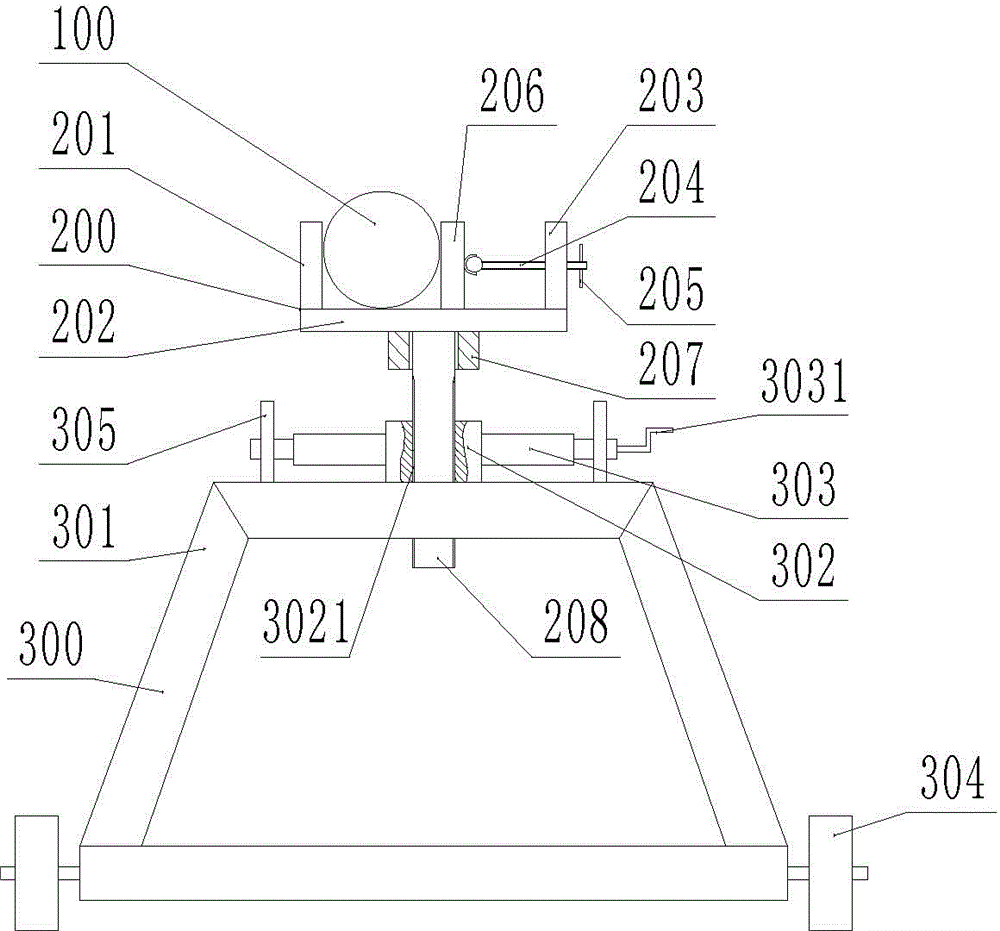

[0014] Such as figure 1 , figure 2 As shown, the feeding trolley of the sawing machine of the present invention is made up of support frame 300 and material frame 200, and material frame 200 comprises material bottom plate 202, material fixed baffle 201, material movable baffle 206, threaded hole plate 203, material fixed baffle 201 is positioned at material The left end of the bottom plate 202, the threaded orifice plate 203 is located at the right end of the material plate 202, and the material movable baffle 206 is located between the material fixed baffle 201 and the threaded orifice 203. A threaded rod 204 is provided between the material movable baffle 206 and the threaded orifice 203, the left end of the threaded rod 204 is ball-hinged with the material movable baffle 206, the threaded rod 204 is threadedly connected with the screwed orifice 203, and the right end of the threaded rod 204 is provided with Rotate rod 205, sleeve 207 is provided at the bottom of material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com