Quick clamping type clamp

A fast and clamping technology, applied in the field of machining, can solve the problems of unreliable clamping, insufficient clamping force, difficult application, etc., and achieve the effect of improving the working efficiency of clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment one, the embodiment of two briquettes

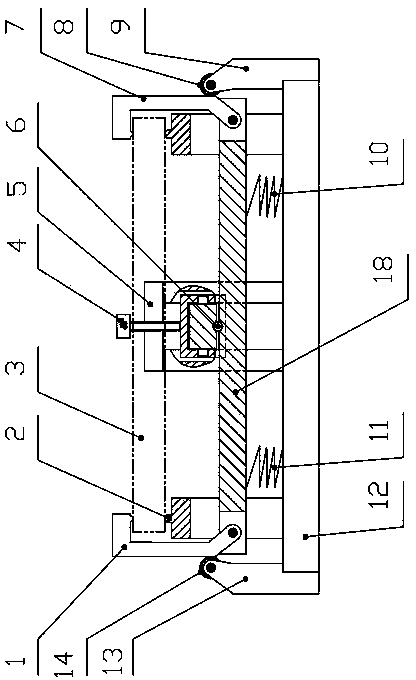

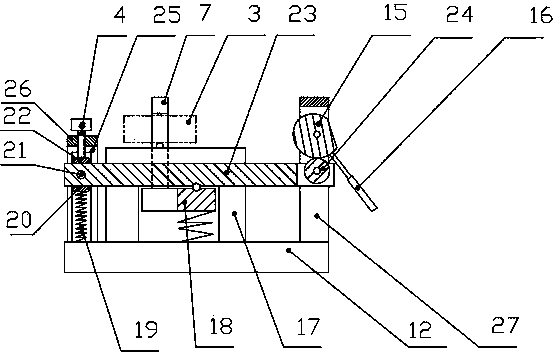

[0024] exist figure 1 with figure 2 Among them, this quick-clamping fixture includes a hook-shaped left pressing block 1 and a right pressing block 7 for clamping the workpiece. A left spring 11 and a right spring 10 are installed between them, a lever 23 is installed between the floating plate 18 and the workpiece 3, one end of the lever 23 is a fulcrum and a fulcrum position adjustment mechanism, and the other end of the lever 23 is a power point and a corresponding power mechanism, The middle part of the lever 23 is in contact with the floating plate 18 through the intermediate piece 6, and the lever 23 transmits force to make the floating plate 18 move, and the floating plate 18 implements clamping or loosening of the workpiece 3 through the pressing block.

[0025] The two briquetting blocks contact the two rollers respectively under the action of their own weight, the left roller 14 is installed on the left rol...

Embodiment 2

[0033] Embodiment two, the embodiment of 3 briquettes

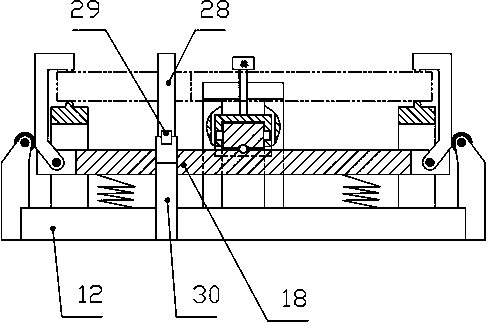

[0034] exist image 3Among them, there are 3 pressure blocks around the floating plate, and a side pressure block 28, a side roller 29, and a side roller support frame 30 are added on the basis of the first embodiment, and the side pressure block 28 is hingedly connected with the floating plate 18, and the rest of the structure Same as Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com