Processing methods of High temperature alloy GH4169 special-shaped hole and hole edge fillet

A GH4169, superalloy technology, applied in the field of mechanical processing, can solve the problems of thin wall, poor rigidity, difficult cutting and processing, etc., and achieve the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Due to the high broaching force in the broaching process of high-temperature alloy GH4169 disc ring parts, the traditional broaching method can no longer meet the actual processing needs, so a milling process was selected to effectively reduce the deformation during processing , to meet processing needs.

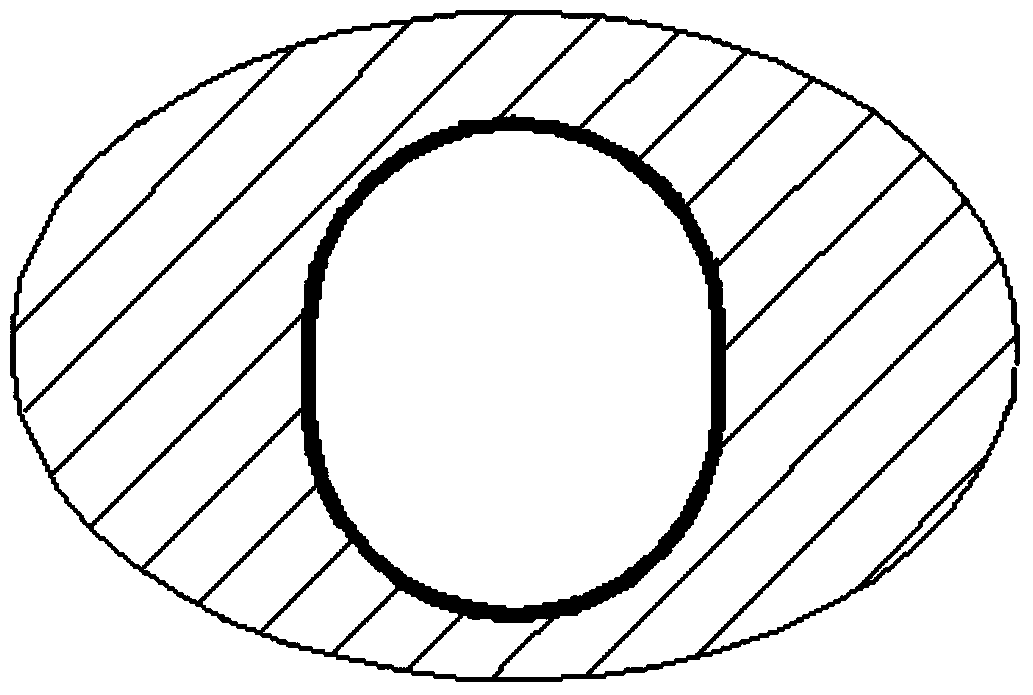

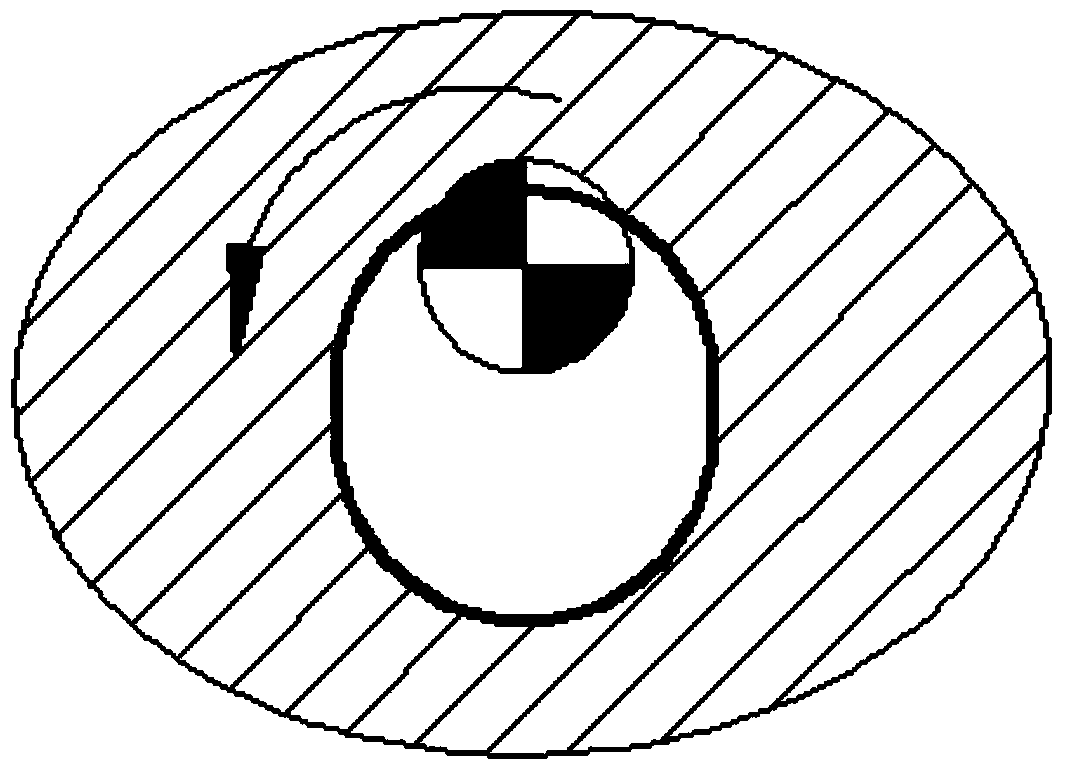

[0024] The processing method of the superalloy GH4169 special-shaped hole, the maximum outer dimension of the processed and formed special-shaped hole is (1mm-3.5 mm)×(2mm-8mm), and the processing steps are as follows:

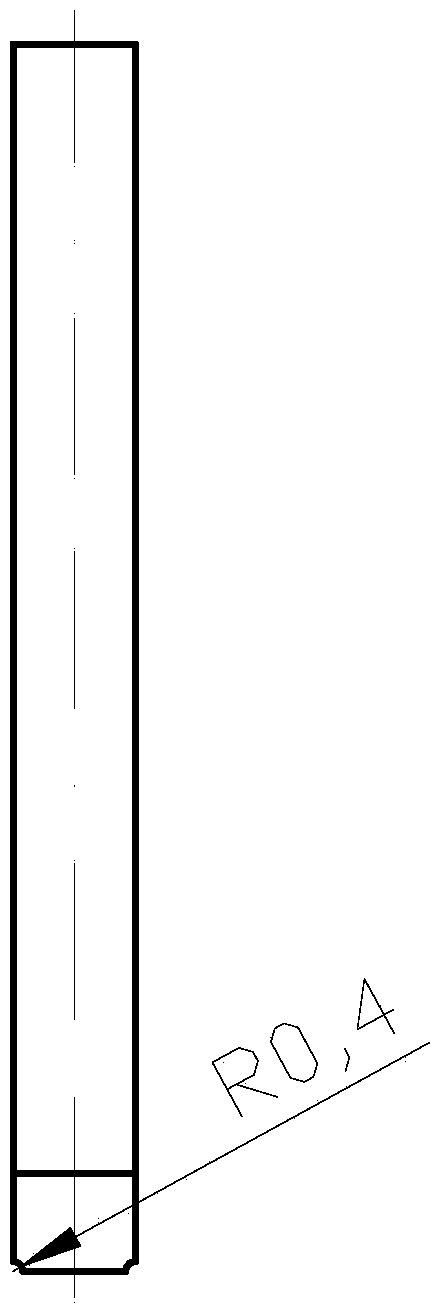

[0025] ① Drilling and drilling the bottom hole: first use the center drill to do the spot, and then choose to use the Ф3 drill bit to drill the bottom hole to remove most of the margin;

[0026] ② Rough milling: use Ф3 milling cutter for rough milling, and move the tool along the contour of the special-shaped hole through the tool center programming, use the three-coordinate machining center, the speed (350r-450r) / min, the feed rate 0.1mm; remove the ...

Embodiment 2

[0036] The processing method of the superalloy GH4169 special-shaped hole, the maximum outer dimension of the processed special-shaped hole is 3.5 mm × 5mm, and the processing steps are as follows:

[0037] ① Drilling and drilling the bottom hole: first use the center drill to do the spot, and then choose to use the Ф3 drill bit to drill the bottom hole to remove most of the margin;

[0038] ② Rough milling: use Ф3 milling cutter for rough milling, and move the tool along the contour of the special-shaped hole through the tool center programming, using a three-coordinate machining center with a speed of 400r / min and a feed rate of 0.1mm; remove the allowance and guarantee it for the next step A uniform margin of 0.2mm is reserved for fine milling;

[0039] ③Finish milling: use Ф3 milling cutter for fine milling, and use the three-coordinate machining center to move along the contour of the special-shaped hole through contour programming, with a speed of 500r / min, and mill to m...

Embodiment 3

[0047]The processing method of the superalloy GH4169 special-shaped hole, the maximum outer dimension of the processed and formed special-shaped hole is 1mm×2mm, and the processing steps are as follows:

[0048] ① Drilling and drilling the bottom hole: first use the center drill to do the spot, and then choose to use the Ф3 drill bit to drill the bottom hole to remove most of the margin;

[0049] ② Rough milling: use Ф3 milling cutter for rough milling, and use tool center programming to move along the contour of the special-shaped hole, using a three-coordinate machining center with a speed of 450r / min and a feed rate of 0.1mm; remove the allowance and ensure that it is the next step A uniform margin of 0.2mm is reserved for fine milling;

[0050] ③Finish milling: use the Ф3 milling cutter for fine milling, move the tool along the contour of the special-shaped hole through contour programming, use a three-coordinate machining center with a speed of 450r / min, and mill to meet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com