Fully enclosed internal circulation organic matter and inorganic matter treatment system

A fully enclosed, treatment system technology, applied in the field of fully enclosed internal circulation of organic matter and inorganic matter treatment systems, can solve the problems of polluted water, harmful gases, pollution crisis, etc., achieve high recycling efficiency, save production costs, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

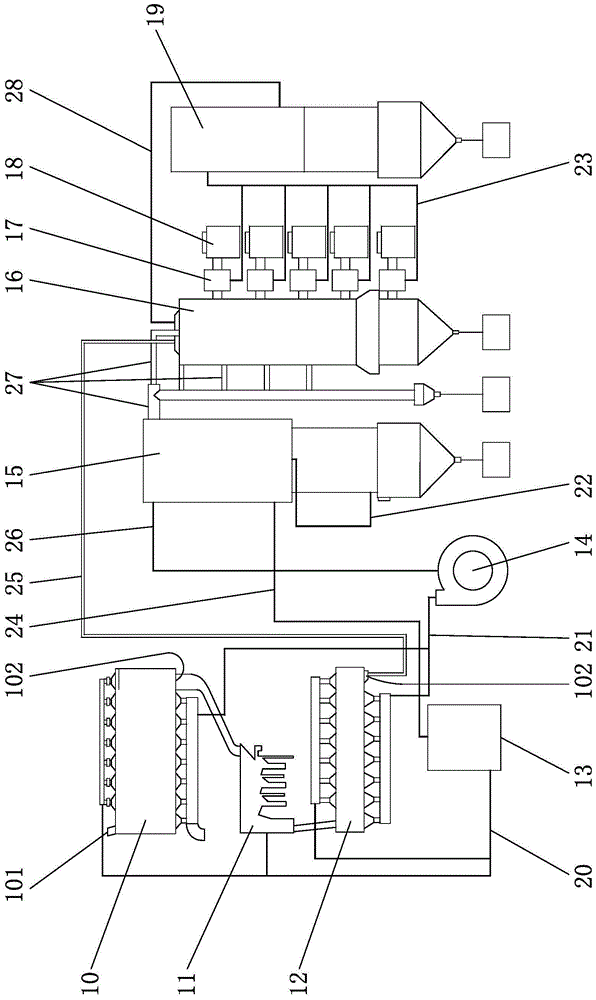

[0030] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 :

[0031] Fully enclosed internal circulation organic matter and inorganic matter treatment system, the residual heat in the furnace after the pyrolysis consumption of the concentrated energy furnace 16 is introduced into the heat exchanger 15 through the pipeline 27 to participate in the air-dried gas circulation system, forming a waste heat recycling system of the concentrated energy furnace 16;

[0032] The hot gas of the heat exchanger 15 is introduced into the air dryer 10 and the air separators 11 and 12 through the pipeline 26, and the waste gas after the air dryer 10 and the air separators 11 and 12 work passes through the pipeline 20 and is purified by the air cleaner 13 and then returns to the air dryer through the pipeline 24. Heater 15 is reused to form a dry air circulation system;

[0033] The product gas produced by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com