Purification adsorbent based on mesoporous molecular sieve material and preparation method and application of purification adsorbent based on mesoporous molecular sieve material

A mesoporous molecular sieve and adsorbent technology, applied in the field of adsorbent and its preparation, can solve the problems of high regeneration temperature, unfavorable energy saving, hydrocarbon polymerization, etc., achieve low regeneration temperature, avoid the disadvantage of high temperature resistance, and low adsorption heat Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

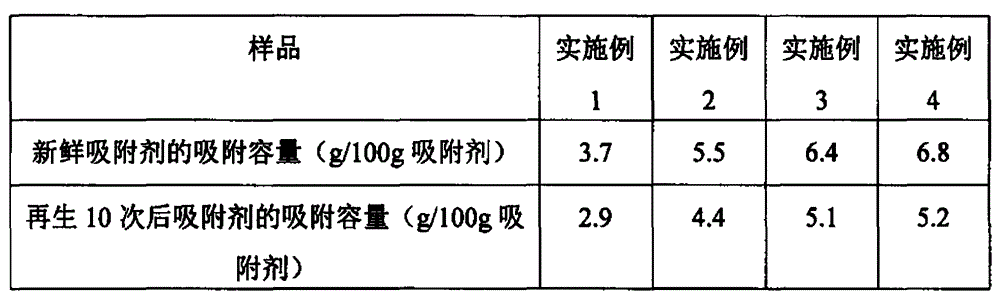

Embodiment 1

[0036] The preparation process of spherical adsorbent containing MCM-41 mesoporous molecular sieve is as follows:

[0037] Using activated alumina or aluminum glue as a binder, mix 50kg (dry basis, the same below) of MCM-41 mesoporous molecular sieve with 45kg of activated alumina, roll into balls in a disc granulator, and use spraying Add sodium hydroxide solution (Na2O dry basis 5kg), shape it into 1-3mm particles and take it out, spray water vapor at 100°C to complete the hydration and aging process, the hydration time is 4 hours, then take it out and dry it at 150°C , and rapidly activated at 400 ° C to obtain a shaped solid adsorbent.

Embodiment 2

[0039] The preparation process of spherical adsorbent containing mesoporous SBA-15 molecular sieve is as follows:

[0040]Using activated alumina or aluminum glue as a binder, mix 35kg of mesoporous SBA-15 molecular sieves with 58kg of activated alumina, roll into balls in a disc granulator, and take them out after forming into 1-2mm particles. Under the condition of ℃, water vapor is sprayed to complete the hydration and aging process. The hydration time is 6 hours, and then it is taken out and dried at 150 ℃, and activated rapidly at 400 ℃ to obtain a molded product. Immerse the solid in 0.5mol / l ZnCl2 solution (dry basis 7kg), immerse at 70°C for 20 minutes, take it out, dry it and then immerse it for 20 minutes, take it out and dry it at 150°C, and dry it at 300°C Under the condition of ℃, it is rapidly activated to obtain the finished solid adsorbent.

Embodiment 3

[0042] The preparation process of the spherical adsorbent containing mesoporous X-type molecular sieve is as follows:

[0043] Using activated alumina or aluminum glue as a binder, mix 55kg of mesoporous X-type molecular sieve, 45kg of activated alumina and 5kg of magnesium carbonate (dry basis), and roll it into a disc granulator to shape it into 2-3mm The granules are taken out, and sprayed with water vapor at 70°C to complete the hydration and aging process. The hydration process lasts for 5 hours, and then taken out and dried at 150°C, and rapidly activated at 450°C to obtain a molded product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com