Pine pollen chewable tablet and preparation method thereof

A technology for chewing tablets and pine pollen, which is applied to the field of chewing tablets of pine pollen and the preparation thereof, can solve the problems of bad eating taste, bitter taste of pine pollen, inconvenient to carry, etc., and achieves alleviating unpleasant bitter taste, convenient eating and carrying. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 A kind of preparation of pine pollen chewable tablet

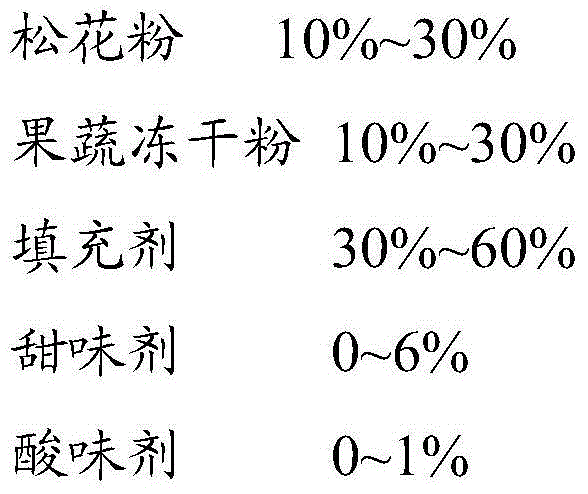

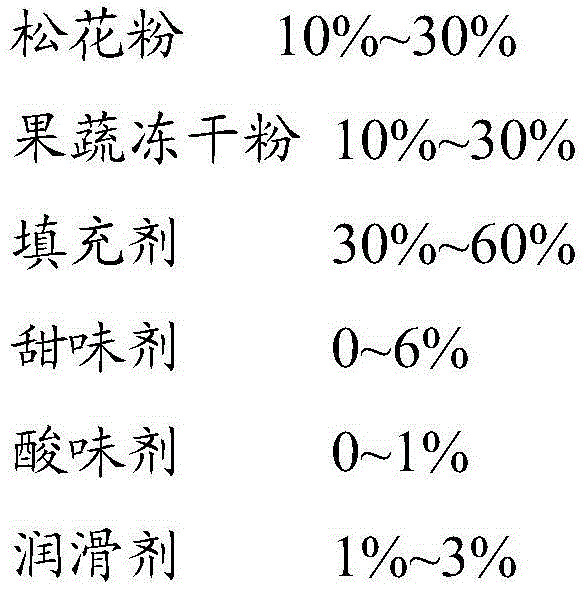

[0027] Pine pollen chewable tablet, raw material parts by weight are composed as follows:

[0028] 30 parts of pine pollen; 15 parts of apple powder; 20 parts of maltodextrin; 15 parts of β-cyclodextrin; 5 parts of microcrystalline cellulose; 15 parts of mannitol; 1 part of magnesium stearate;

[0029] Its production method comprises the steps of:

[0030] Screening: pass the large-grained material through an 80-mesh rotary vibrating sieve, and return the raw material larger than 80-mesh to the pretreatment room for re-grinding;

[0031] Mixing: Put the screened ingredients in a tank mixer and stir for 15 minutes as needed to make the materials evenly mixed. Add 75% alcohol to the mixed powder, add a small amount each time, and stir constantly to make the mixed powder wet evenly. When the mixed powder is completely wet, the soft material made by hand is kneaded into a ball, and it can be easily dispe...

Embodiment 2

[0037] Embodiment 2 A kind of preparation of pine pollen chewable tablet

[0038] Pine pollen chewable tablet, raw material parts by weight are composed as follows:

[0039] 30 parts of pine pollen powder; 24 parts of fruit and vegetable freeze-dried powder; 15 parts of maltodextrin; 12 parts of β-cyclodextrin; 4 parts of microcrystalline cellulose; Magnesium acid 1 part;

[0040] Its production method comprises the steps of:

[0041] Screening: pass the large-grained material through an 80-mesh rotary vibrating sieve, and return the raw material larger than 80-mesh to the pretreatment room for re-grinding;

[0042] Mixing: Put the screened ingredients in a tank mixer and stir for 15 minutes as needed to make the materials evenly mixed. Add 75% alcohol to the mixed powder, add a small amount each time, and stir constantly to make the mixed powder wet evenly. When the mixed powder is completely wet, the soft material made by hand is kneaded into a ball, and it can be easily...

Embodiment 3

[0048] Embodiment 3 A kind of preparation of pine pollen chewable tablet

[0049] Pine pollen chewable tablet, raw material parts by weight are composed as follows:

[0050] 23 parts of pine pollen powder; 18 parts of fruit and vegetable freeze-dried powder; 14 parts of maltodextrin; 11 parts of β-cyclodextrin; 10 parts of microcrystalline cellulose; 5 parts of non-dairy creamer; 19 parts of mannitol; 1 part of citric acid; 1 part magnesium stearate;

[0051] Its production method comprises the steps of:

[0052] Screening: pass the large-grained material through an 80-mesh rotary vibrating sieve, and return the raw material larger than 80-mesh to the pretreatment room for re-grinding;

[0053] Mixing: Put the screened ingredients in a tank mixer and stir for 15 minutes as needed to make the materials evenly mixed. Add 75% alcohol to the mixed powder, add a small amount each time, and stir constantly to make the mixed powder wet evenly. When the mixed powder is completely ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com