Single-end electric heating tube structure with double insulation protection function and manufacturing method thereof

A technology of insulation protection and electric heating tube, which is applied in the direction of ohmic resistance heating components and the shape of heating elements, etc., can solve the problems of large space occupied by protective components, decrease of carrying power density, temperature limitation of protective components, etc., to improve insulation performance and The effect of thermal conductivity, increase of loadable power density, and increase of effective heating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with accompanying drawing:

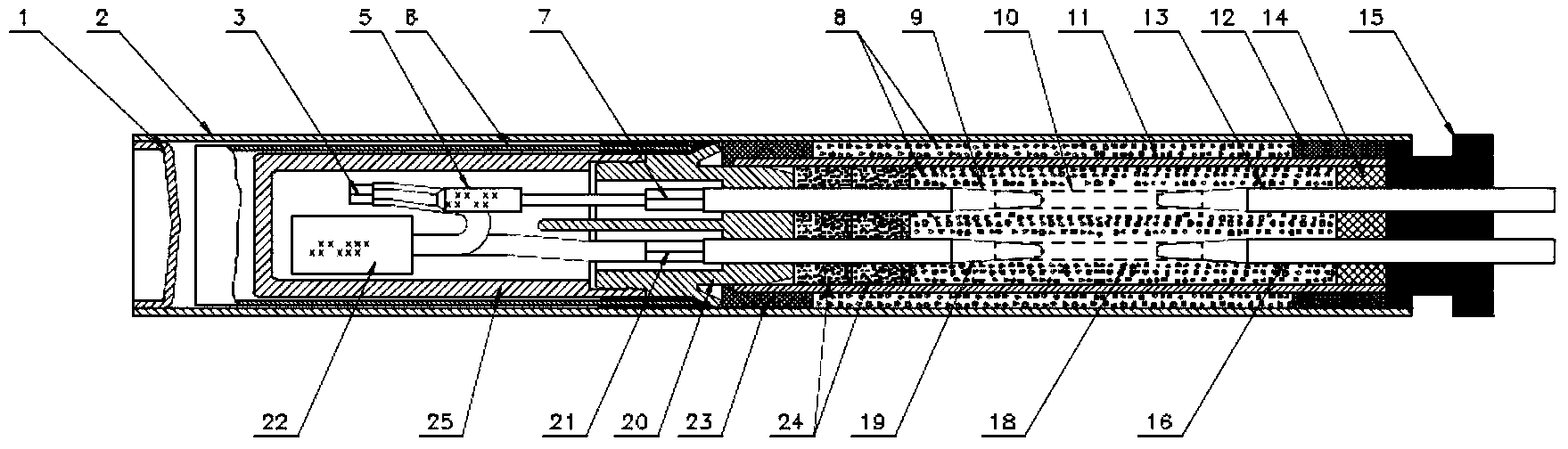

[0030] as attached Figures 2 to 5 Shown, the structure of the present invention comprises outer pipe 2, inner assembly (such as image 3 shown); where the inner assembly includes two sets of inner tube components, terminals, inner sleeve 4, outer sleeve 6, fuse 5 and temperature controller 22; the first set of inner tube components includes inner tube 11, upper lead-out rod 13 , lower lead rod 9, resistance wire 10, inner plug 14 and magnesium oxide powder 8; the second group of inner tube components includes inner tube 17, upper lead rod 16, lower lead rod 19, resistance wire 18, inner plug 14 and magnesium oxide Powder 8. It is characterized in that: the upper lead-out rod 13 and the lower lead-out rod 9 are respectively connected to both ends of the resistance wire 10, and the connected upper lead-out rod 13, resistance wire 10 and lower lead-out rod 9 are inserted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com