A Piezoelectric Modulated Vertical Cavity Semiconductor Laser Structure

A vertical cavity and semiconductor technology, applied in the direction of semiconductor lasers, lasers, devices for controlling output parameters of lasers, etc., can solve the problem of single modulation mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

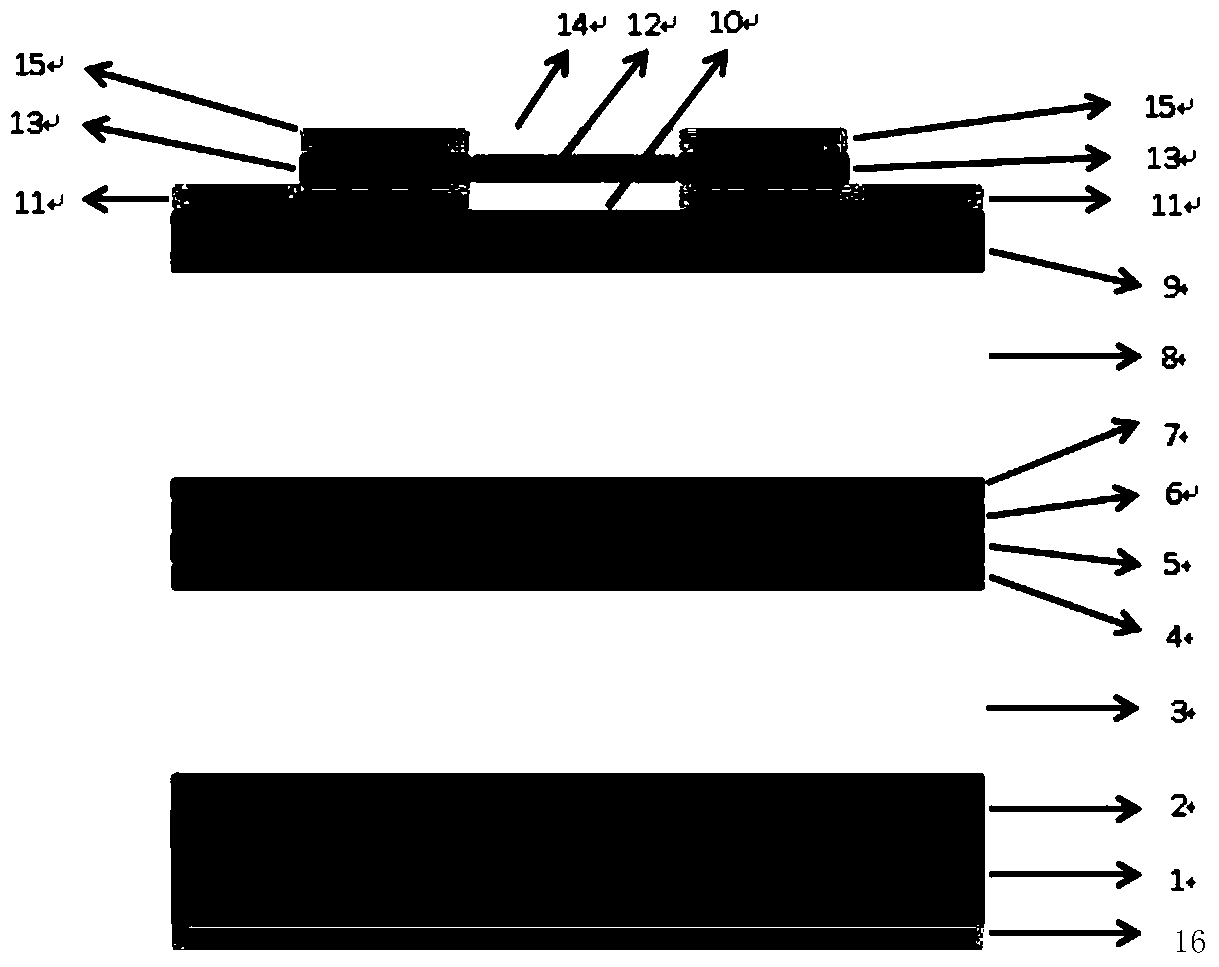

[0052] The structure of the piezoelectric modulation vertical cavity semiconductor laser used in the present invention is: the MOCVD (metal organic chemical vapor deposition) epitaxial growth method is adopted. Such as figure 1 Shown:

[0053]In n-GaAs(100)(Si:2x10) with a width of 250um 18 / cm 2 ) grow n-GaAs (Si: 2x10 18 / cm 2 ) buffer layer 2;

[0054] In n-GaAs (Si:2x10 18 / cm 2 ) on the buffer layer 2 grows 20 pairs of λ / 4 periodically repeated Al 0.9 Ga 0.1 As(81.7nm) / GaAs(69.6nm)(Si:2x10 18 / cm 2 ), forming an n-type DBR reflector 3;

[0055] Growth of n-Al with a thickness of 72.3 nm on the n-type mirror 3 0.2 Ga 0.8 As(Si:1×10 18 / cm 3 ) lower carrier confinement layer 4;

[0056] Gain region 5 with 3 quantum wells is grown on carrier lower confinement layer 4 (well material is In 0.2 Ga 0.8 As thickness is 8nm, barrier material is GaAs thickness is 10nm);

[0057] Growth of p-Al with a thickness of 72.3nm on the gain region 5 0.2 Ga 0.8 As(C:1×10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com