Turbidity sensor and turbidity measurement device

A turbidity sensor and turbidity value technology, applied in the measurement of scattering characteristics, etc., can solve the problems of inability to meet the requirements of miniaturization, portability, affecting measurement accuracy, and complex structure and installation, so as to eliminate adverse effects and simplify the overall structure design. , the effect of improving the measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in detail:

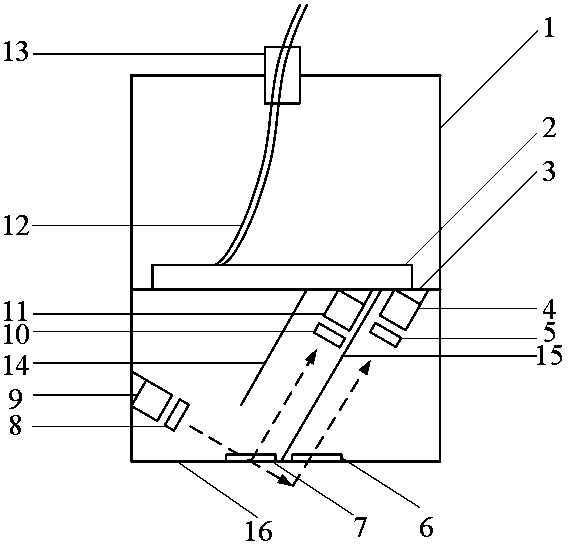

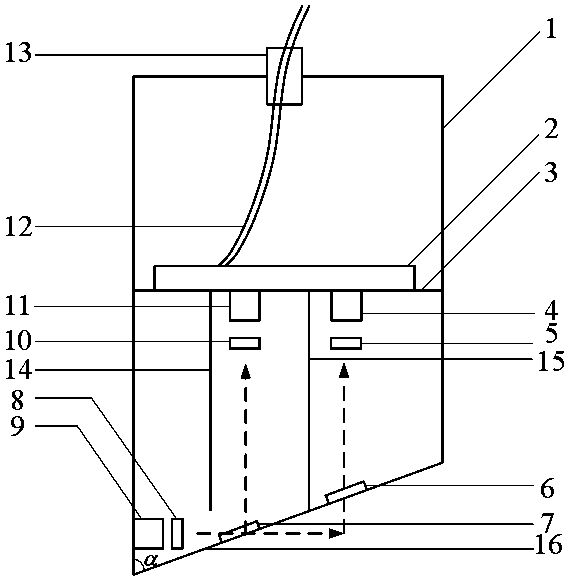

[0020] figure 1 An embodiment of the turbidity measurement device of the present invention is shown, the measurement device comprising a turbidity sensor and a signal processing module. like figure 1 As shown, the turbidity sensor includes a barrel-shaped casing 1. The casing 1 can be in the shape of a round barrel or a square barrel, and the top of the casing 1 can be open or closed. In this embodiment, the bottom surface 16 of the housing 1 is perpendicular to the side wall of the housing, and an LED light source 9 is arranged on the inner side of the side wall of the housing 1 close to the bottom surface 16; The light emitted by 9 is collimated so that parallel light (the dotted line in the figure is the light path) is directed to the bottom surface 16 of the casing, and the included angle between the parallel light and the bottom surface 16 of the ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com