Auxiliary block for connecting rod fatigue test

A fatigue test and spacer technology, applied in the testing of mechanical parts, the testing of machine/structural parts, and the use of applied stable tension/pressure to test the strength of materials, etc. problems, to achieve the effect of improving lifespan or stamina, suitable for promotion and use, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

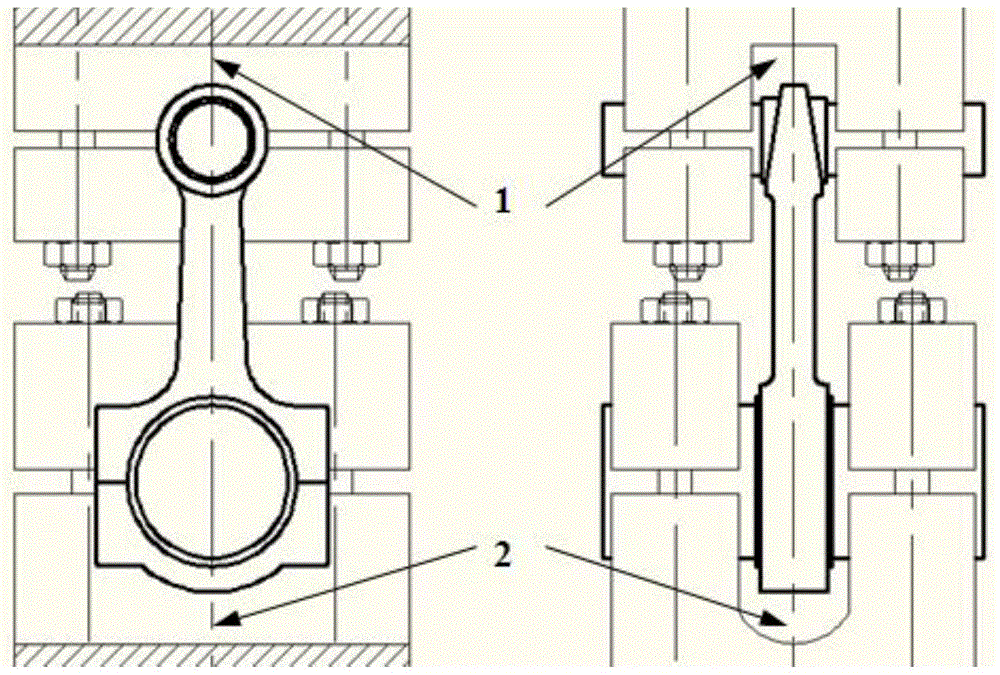

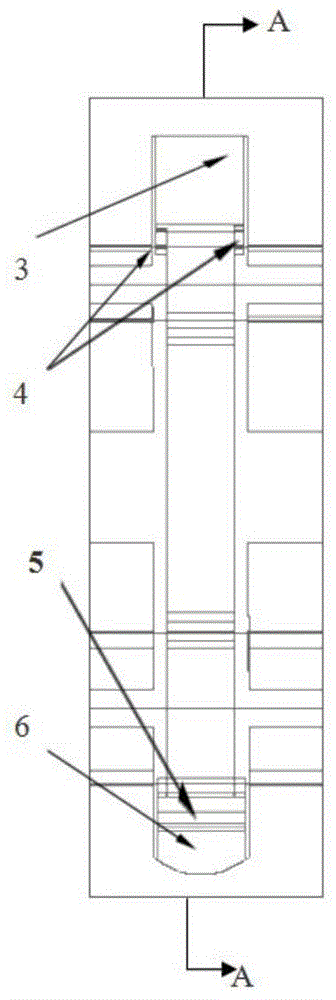

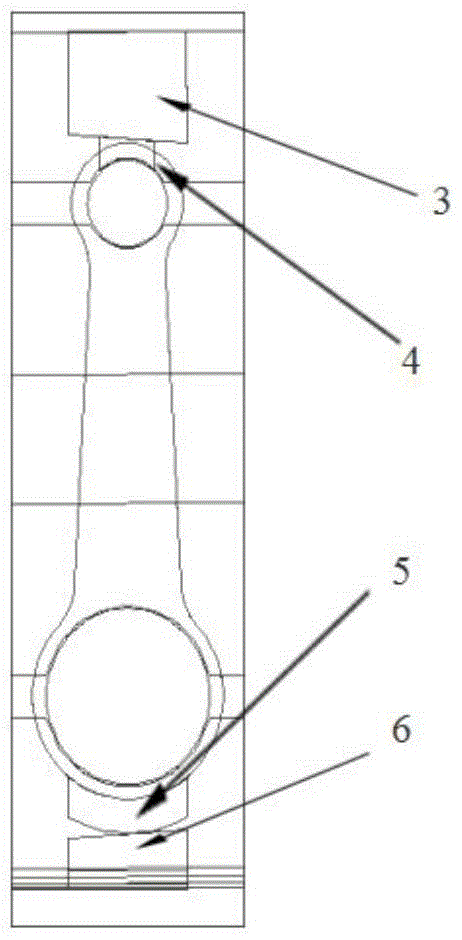

[0053] Such as Figure 3 to Figure 5 As shown, the connecting rod fatigue test auxiliary block includes a first wedge block 3, a second wedge block 6, a first arc block 5, a first shoulder block 4 and a second shoulder block;

[0054] The first wedge-shaped pad 3, which is a right-angled trapezoid, is located at the bottom of the groove bottom of the connecting rod fatigue fixture clamping the big end of the connecting rod or the flat bottom of the small end of the connecting rod, such as Figure 6(a)-6(d) shown;

[0055] The second wedge block 6, such as Figure 7(a)-7(d) As shown, the spacer is composed of a right-angled trapezoid and an arc body, and the arc body is arranged on the right-angle surface of the right-angle trapezoid body. The chord length of the arc of the cross-section is equal to the length of the right-angled side of the right-angled surface. The cross-section of the arc body is perpendicular to the right-angled trapezoid of the cross-section of the right-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com