Plastic-coated composite steel tube

A technology for composite steel pipes and steel pipes, applied in the field of steel pipes, can solve problems such as inseparable transportation pipes, sealing performance, anti-corrosion performance, mechanical strength of fluid resistance, and application range of service life that cannot meet the needs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

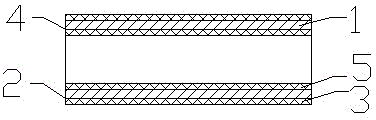

[0013] A plastic-coated composite steel pipe comprises a steel pipe body 1 , an outer epoxy resin layer 3 is provided on the outer wall 2 of the steel pipe body 1 , and an inner epoxy resin layer 5 is provided on the inner wall 4 of the steel pipe body 1 .

[0014] The diameter of the steel pipe body 1 is 50-1200mm.

[0015] The thickness of the outer epoxy resin layer 3 is 0.30-0.5mm. .

[0016] The thickness of the inner epoxy resin layer 5 is 0.30-0.45mm.

[0017] Due to the adoption of the above structure, compared with plastic pipes, the present invention has the advantages of high mechanical strength, corrosion resistance, small friction coefficient, long service life, etc. etc., and the application range of the present invention is wider, and at the same time, it also has good weather resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The way to | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com