A Fracturing Window Isolation Tool and Technology for a Branch Well

A branch well and window technology, applied in the direction of sealing/isolation, wellbore/well components, production fluid, etc., can solve problems such as large well control risks, and achieve the effect of preventing well control risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

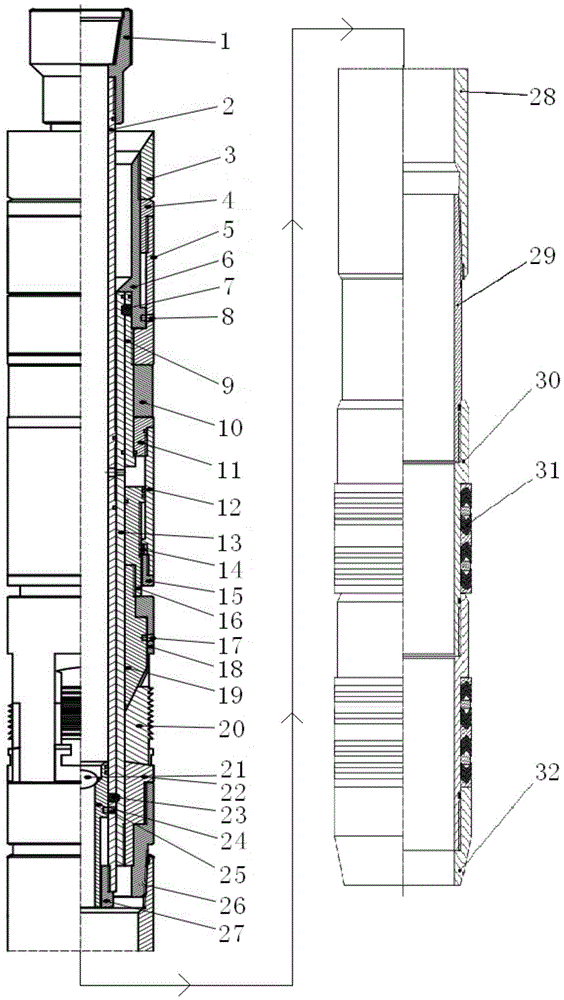

[0016] Such as figure 1 As shown, a lateral well fracturing window isolation tool includes a feeding pipe joint 1, a feeding pipe 2, an outer central pipe 9, an inner central pipe 13, a ball 21, a flushing pipe 28 and a return insertion pipe; 2. The upper end is connected to the feeding pipe joint 1. The outer side of the feeding pipe 2 is fitted with an inner center pipe 13 and locked by the lock block 23. The ball seat 24 is connected to the inner wall of the feeding pipe 2 through the locking pin 25 and blocks the locking lock. Block 23, the inner wall of the bottom end of the feed pipe 2 is connected to the stop sleeve 27 to prevent the ball seat 24 from falling into the bottom. The outer central tube 9 is set on the outer side of the inner central tube 13 and is locked by the lock block 7. The unsealing outer cylinder 5 is connected to the outer side of the outer central tube 9, and the back insertion tube 6 is connected to the inner wall of the unsealing outer cylinder 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com