Method for brewing grape flavor type white wine

A technology of liquor and aroma type, which is applied in the preparation of wine, the method based on microorganisms, and the preparation of alcoholic beverages, etc. It can solve the problems of insufficient nutrients in grape liquor, failure to impregnate grape skins, and low nutrient content, etc., to achieve It is beneficial to human health, the taste is mellow, soft and refreshing, and the effect of increasing the concentration of tannins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The brewing method of Portuguese-flavored liquor is as follows:

[0022] 1. Selected wild grapes as the raw material for wine making, compared with the existing raw materials for grape white wine production, the content of various nutrients in wild grapes is significantly higher than other Eurasian grapes.

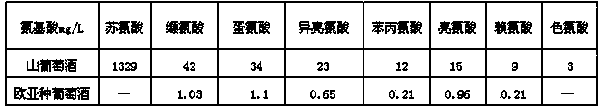

[0023] (1) Amino acid composition in mountain wine

[0024] Amino acids are important nutrients in wine. Compared with European and Asian wines, mountain wine has the highest content of eight essential amino acids.

[0025]

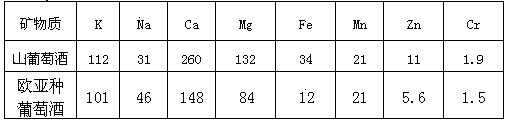

[0026] (2) Mineral composition in mountain wine

[0027] Minerals are important ingredients in the human body. Mountain wine contains a higher variety of minerals, which are higher than those of European and Asian wines except sodium.

[0028]

[0029] (3) Dry extract of mountain wine

[0030] The dry soak content is the quality standard of the main components of wine. Compared with Eurasian wine, the dry soak content of wild grape is higher, reaching 36-...

Embodiment 2

[0043] The brewing method of Portuguese-flavored liquor is as follows:

[0044] (1) After 10 tons of wild grapes are de-stemmed and broken, the grape juice and pomace are mixed and dipped to extract aromatic substances. The immersion time is 72 hours; the aromatic components in the solid grapes enter the liquid part at a temperature of 8°C.

[0045] (2) The grape juice is separated from the skin residue, and the grape juice is heated and concentrated in a vacuum at a concentration temperature of 65°C. Reduce its volume to 2 tons.

[0046] (3) The concentrated grape juice is fermented with 0.008% active dry yeast, and the temperature is controlled at 29°C. When the sugar content is less than 2g / L, the fermentation is terminated.

[0047] (4) The concentrated grape juice after fermentation is continuously distilled using a distillation tower, the distillation temperature is 75°C, and the steam pressure is 0.2MPA to produce distilled wine.

[0048] (5) The above distilled spirits are filt...

experiment example

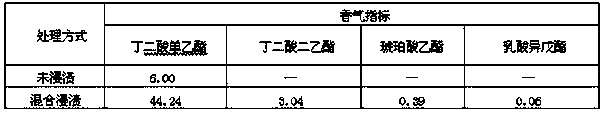

[0049] Experimental example: Mixed dipping process effect detection (product detection results of Example 2) The following table shows the product detection results

[0050]

[0051]

[0052] Compared with the non-dipping process, the mixed dipping process has a significant impact on the color, total phenols and tannins of the wine, and the concentration of total phenols and tannins of the wine after the dipping process is significantly increased. Alcohol fermentation is normal, the obtained wine has a strong structure, contains a variety of aroma-forming substances, and the sensory evaluation is higher than that of the un-dipped process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com