Methyl tert-butyl ether crude product purification method and methyl tert-butyl ether production method

A technology of methyl tertiary butyl ether and crude product, applied in the field of purifying methyl tertiary butyl ether crude product, can solve the problems of difficult separation, high energy consumption, and difficulty in reaching 10 mg/kg of sulfur content, reducing the The effect of investment and maintenance costs, energy saving and energy reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

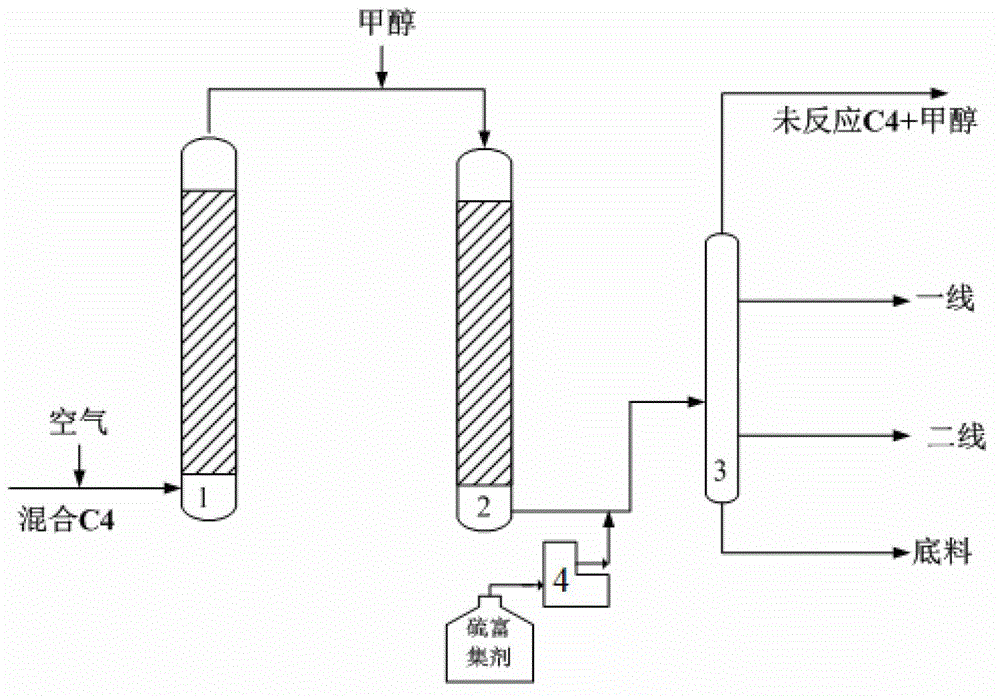

[0079] according to figure 1 Shown flow process produces ultra-low sulfur methyl tert-butyl ether, concretely carries out as follows:

[0080] Among them, "1" is the mixed C4 catalytic oxidation tower, "2" is the main reactor, "3" is the azeotropic distillation tower, "4" is the sulfur enrichment agent injection pump; the sulfur content in the mixed C4 of the feed is 43.6 mg / kg, wherein the mercaptan sulfur content is 35.8mg / kg, of which, C3 (propane+propylene) is 0.08% by mass, isobutane is 36.54% by mass, isobutene is 23.20% by mass, and 1-butene is 11.65% by mass, 9.45% by mass of n-butane, 18.55% by mass of 2-butene (cis + trans), 0.55% by mass of C5 and above.

[0081] (1) Inject air into the mixed C4, and control the amount of air so that the amount of oxygen contained is 150% (mol) of the oxygen required to oxidize mercaptan sulfur. According to the content of mercaptan sulfur of 35.8mg / kg, the amount of air injected is kg of C4 is injected with 45mL (about 56mg) of a...

Embodiment 2

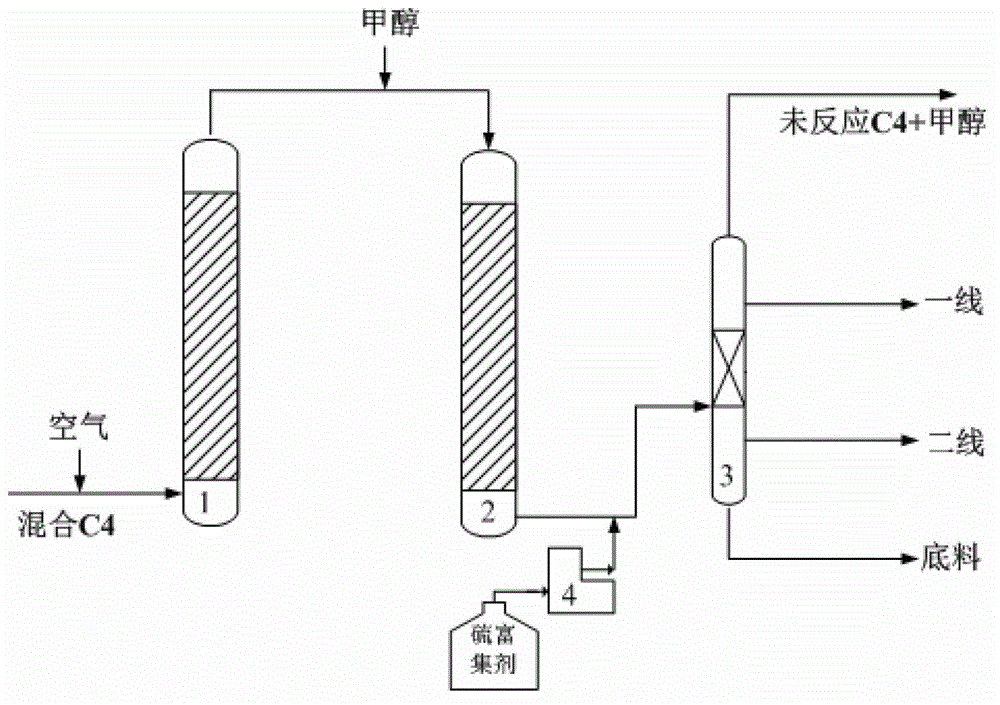

[0101] according to figure 2 Shown flow process produces ultra-low sulfur methyl tert-butyl ether, concretely carries out as follows:

[0102] Among them, "1" is the mixed C4 catalytic oxidation tower, "2" is the main reactor, "3" is the catalytic distillation tower, and "4" is the sulfur enrichment agent injection pump: the sulfur content in the mixed C4 feed is 43.6mg / kg, of which, the mercaptan sulfur content is 35.8 mg / kg, C3 (propane+propylene) 0.08 mass%, isobutane 36.54 mass%, isobutene content is 23.20 mass%, 1-butene 11.65 mass%, n-butane 9.45 mass%, 2-butene (cis + trans) 18.55 mass%, C5 and above 0.55 mass%.

[0103] (1) Inject air into the mixed C4, and control the amount of air so that the amount of oxygen contained is 120% (mol) of the oxygen required to oxidize mercaptan sulfur. According to the content of mercaptan sulfur of 35.8mg / kg, the amount of air injected is kg of C4 is injected with 38mL (about 48mg) of air, and the injected air is quickly dissolved...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com