Novel method for separating ethylene glycol and 1,2-pentanediol

A technology of ethylene glycol and pentanediol, applied in the field of separation engineering, can solve problems such as difficult separation, and achieve the effects of strong practicability and strong device operation stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

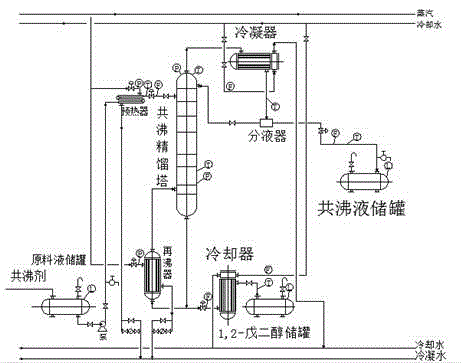

[0012] The azeotropic rectification column is adopted and operated intermittently, and the raw material is a mixture of ethylene glycol-1,2-pentanediol-zeotrope (which contains ethylene glycol: 1,2-pentanediol: entrainer mass ratio 2:1:2), the operating pressure is set to 40kpa, and the reflux ratio is 15. The temperature at the top of the tower is stable at about 145°C, and the temperature at the bottom of the tower changes from 160°C to 169°C. The azeotropic liquid of ethylene glycol and entrainer is obtained at the top of the tower, and the azeotrope content reaches 99.9% by adjusting the reflux ratio. The azeotropic distillation operation has obtained a very good separation effect, which proves that this method can obtain azeotropes with a rectification column.

example 2

[0014] Adopt the equipment and operating conditions of the above example to carry out continuous rectification operation, and feed from the middle and bottom of the rectification tower at normal temperature. The azeotrope can still be obtained at the top of the tower. After the stable production, the qualified 1,2-pentanediol product can be obtained in the bottom of the tower by adjusting the reflux ratio and continuing the rectification, with a purity of more than 98%.

example 3

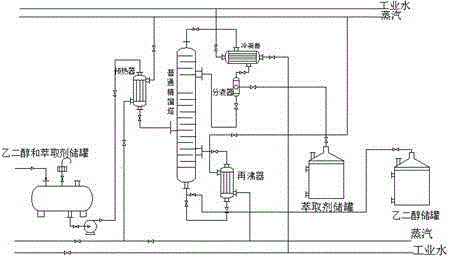

[0016] The top azeotropes of the above two examples were collected, extracted with an extractant, and filtered. The filtrate was a mixed solution of ethylene glycol and the extractant, and the filter cake was an azeotrope. After drying, the purity of the entrainer finally obtained is 99.5%. The mixed solution of ethylene glycol and extractant is separated by a common rectification tower to obtain qualified ethylene glycol products with a purity of over 98%, and the obtained extractant can be recycled.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com