Preparation method of high performance underwater concrete

A kind of underwater concrete, high-performance technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the inconvenience of transportation, loading and unloading, storage and mechanical construction, the difficulty of raw material loading and unloading and storage into practice, Problems such as harsh construction environment, to achieve good underwater dispersion resistance, reduce construction costs, and simple construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

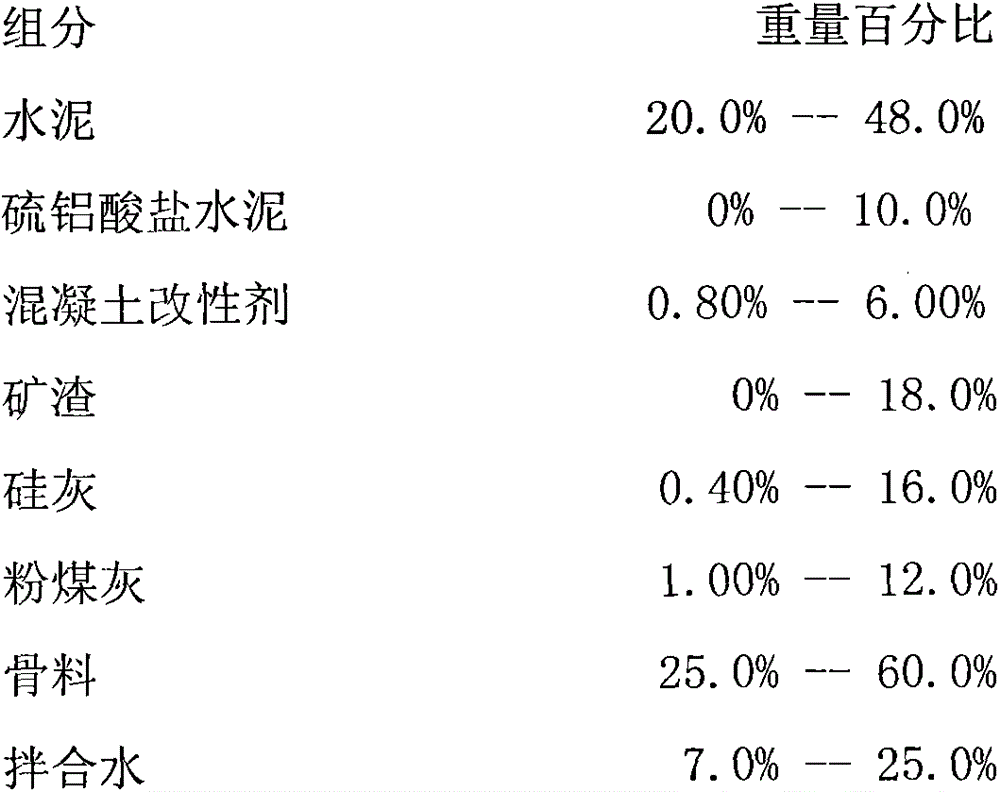

[0029] Underwater concrete formulated with Portland cement:

[0030] Table 1:

[0031]

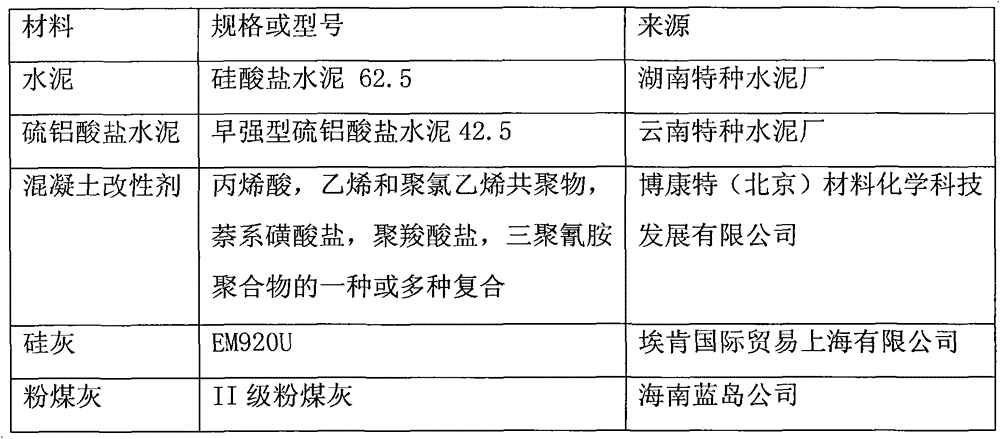

[0032] Underwater concrete formulated with Portland cement:

[0033] Portland cement 62.528.4%, early strength sulphoaluminate cement 42.51.20%, concrete modifier 2.41%, silica fume 3.35%, fly ash 3.24%, aggregate (sandstone) 48.20%, sea water 13.2%,. After accurately weighing the raw materials according to the proportion, mix them with a concrete mixer, add sea water while stirring, and after stirring for 10 minutes, pour the mixed concrete into 4cm×4cm×16cm and 15cm×15cm×15cm that have been placed in water 20cm deep In the mold, take out the test mold from the water after 6 hours, scrape the surface of the mold with a scraper, put it in the water again for curing for 24 hours, measure the compressive strength of the mortar for 1 day after removing the mold, and put the other test pieces in seawater at room temperature for curing to test age.

[0034] After testing, the 1-day compr...

Embodiment 2

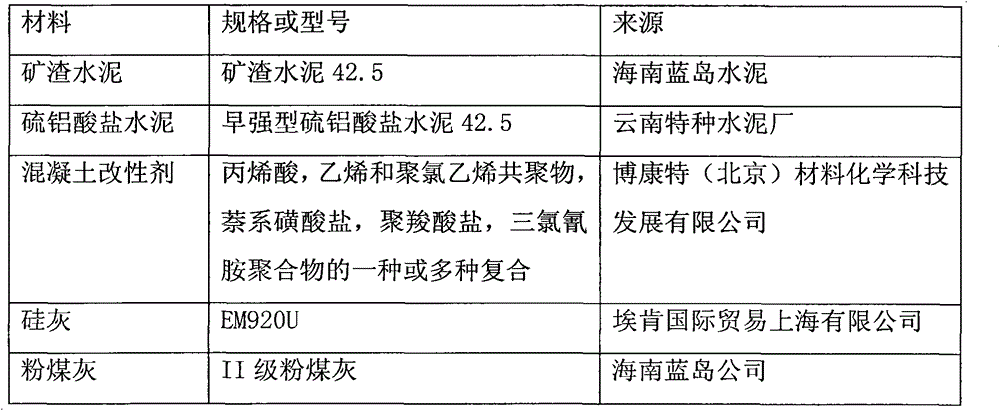

[0036] Underwater concrete made with slag cement

[0037] Table 2

[0038]

[0039] Underwater concrete formulated with slag cement:

[0040] Slag cement 42.533.10%, early strength sulphoaluminate cement 42.51.62%, concrete modifier 2.64%, silica fume 3.12%, fly ash 1.62%, aggregate (sandstone) 45.20%, seawater 12.7% ,. After accurately weighing the raw materials according to the proportion, mix them with a concrete mixer, add sea water while stirring, and after stirring for 10 minutes, pour the mixed concrete into 4cm×4cm×16cm and 15cm×15cm×15cm that have been placed in water 20cm deep In the mold, take out the test mold from the water after 6 hours, scrape the surface of the mold with a scraper, put it in the water again for curing for 24 hours, measure the compressive strength of the mortar for 1 day after removing the mold, and put the other test pieces in seawater at room temperature for curing to test age.

[0041] After testing, the 1-day compressive strength of ...

Embodiment 3

[0043] Underwater concrete formulated with slag cement:

[0044] Slag cement 42.536.10%, early strength sulphoaluminate cement 42.51.80%, concrete modifier 2.51%, silica fume 2.69%, fly ash 1.83%, aggregate (sandstone) 35.37%, seawater 14.3% ,. After accurately weighing the raw materials in proportion, stir with a concrete mixer, add seawater while stirring, and after stirring for 5-10 minutes, weigh 5.40% of the polymer resin after water absorption, add it to the concrete mixer, and continue stirring for 1- For 2 minutes, pour the mixed concrete into the 4cm×4cm×16cm and 15cm×15cm×15cm molds that have been placed in water 20cm deep. After 6 hours, take out the test mold from the water, scrape the surface of the mold with a scraper, and then reset it. Put it in water for curing for 24 hours, measure the compressive strength of the mortar for 1 day after removing the formwork, and put the other test blocks in seawater at room temperature for curing until the test age.

[0045...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com