Transmission system capable of adjusting tension of base materials and control method thereof

A technology of transmission system and control method, which is applied in the field of transmission system, can solve the problems affecting the profit of the industry, the reduction of process yield, damage, etc., and achieve the effects of rapid response to labor costs, saving labor costs, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

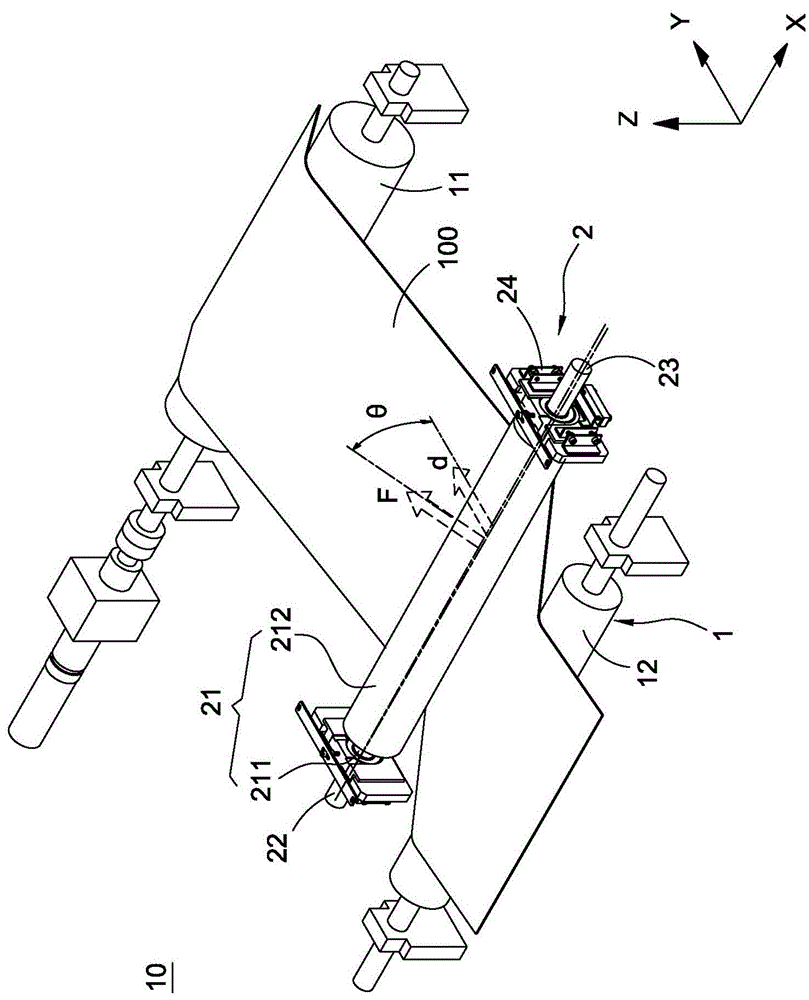

[0074] The detailed description and technical content of the present invention will be described as follows with accompanying drawings, but the attached drawings are only for illustration purposes and are not intended to limit the present invention.

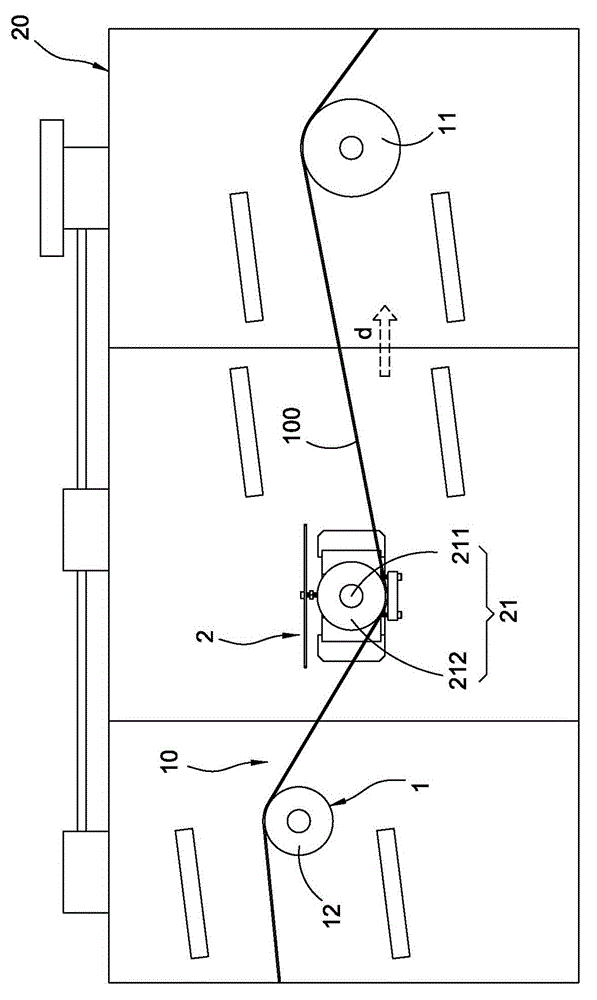

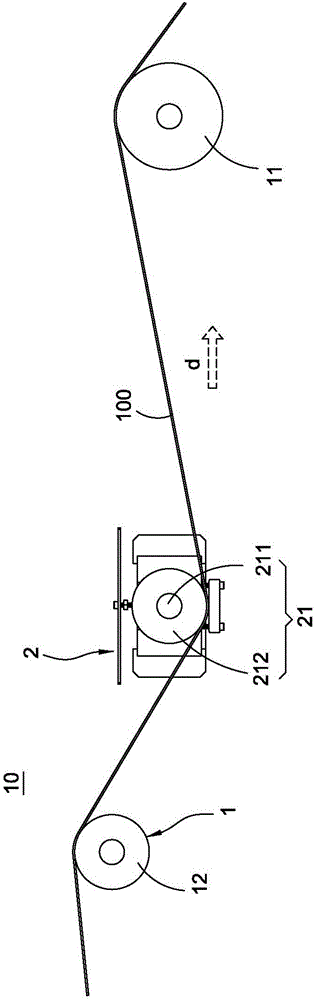

[0075] Please refer to Figure 1 to Figure 3 Shown is the first embodiment of the conveying system of the present invention. The present invention provides a conveying system with adjustable substrate tension and a control method thereof for conveying a substrate 100. The conveying system 10 is used in a processing device 20 , the transmission system 10 mainly includes a transmission mechanism 1 and a roller assembly 2 .

[0076] The substrate 100 can be thin films such as ITO film, copper foil, aluminum foil, polarizing film, glass fiber film or nickel-iron alloy film.

[0077] The processing equipment 20 can be a washing machine, developing machine, etching machine, stripping machine, coating machine, exposure machine, slittin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com