Tortoise jelly assembly equipment

A technology for assembling equipment and Guiling ointment is applied in the field of assembling equipment for Guiling ointment, which can solve the problems of food contamination with large bacteria, lack of special equipment, food safety problems, etc., and achieve the effects of ensuring food safety and hygiene, low production cost and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

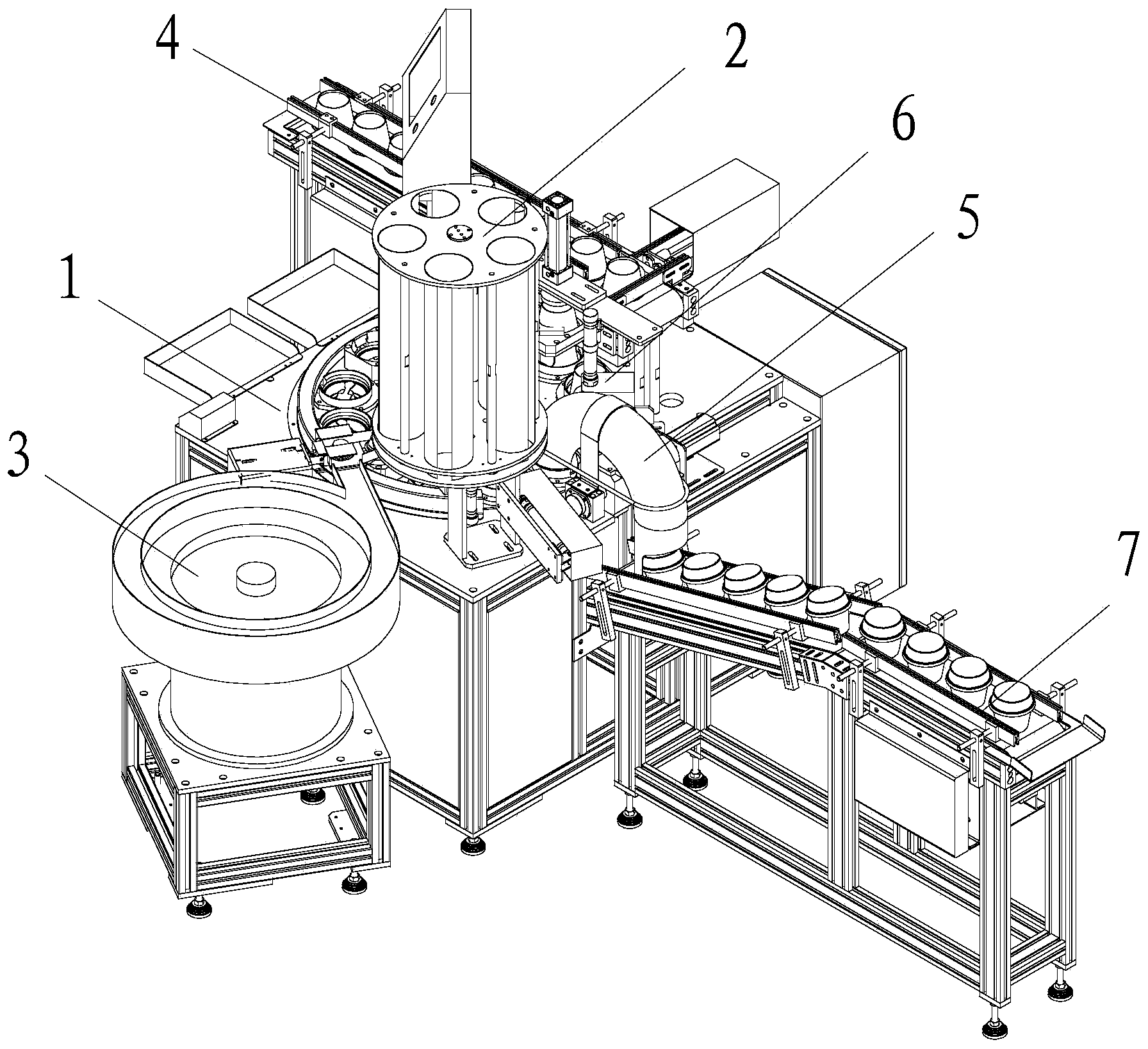

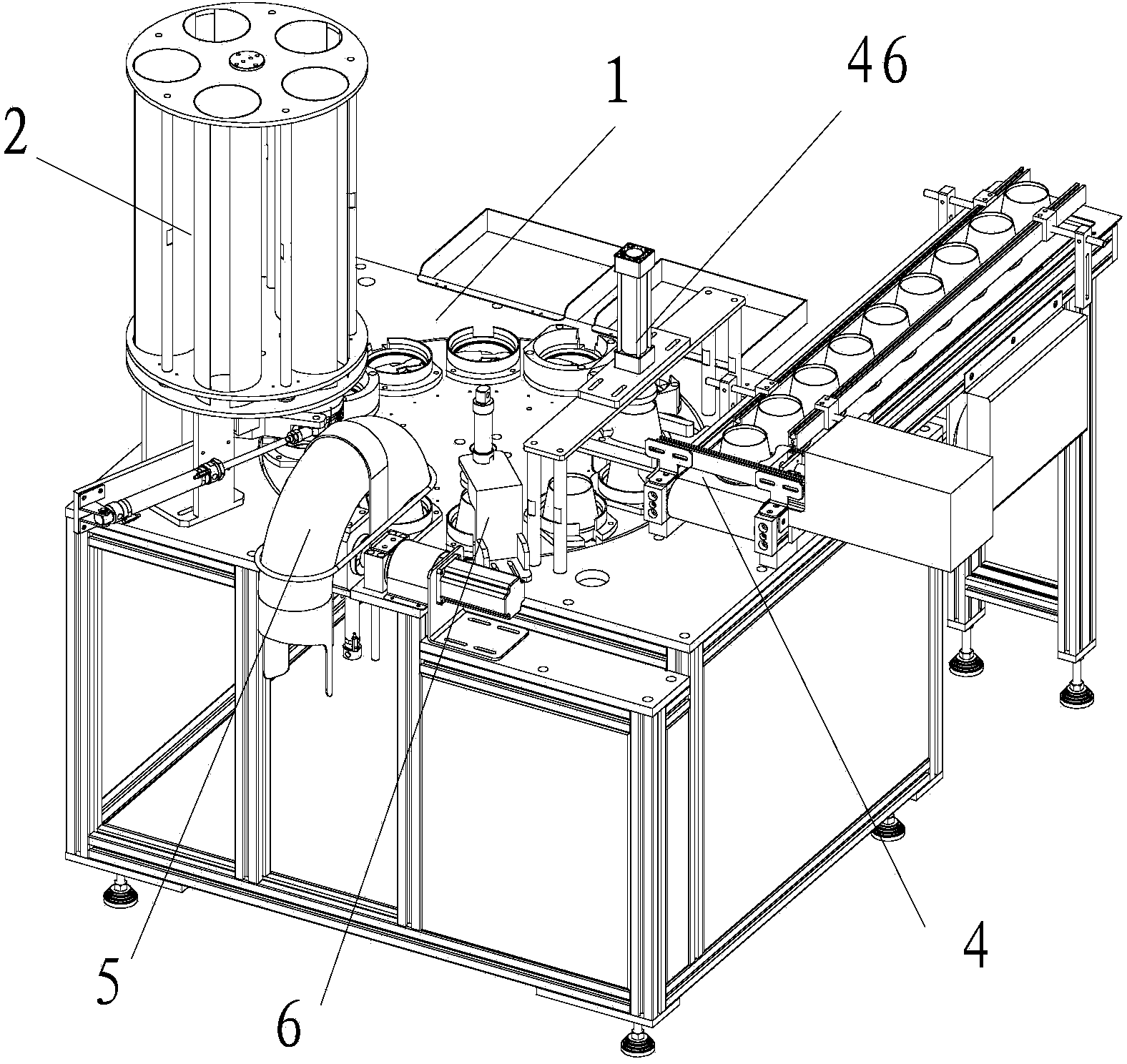

[0044] The equipment of this embodiment is used for the assembly of Guiling jelly; its structure is as follows figure 1 and figure 2 shown. The equipment includes a control device and an assembly table 1, and a cover body feeding device 2, a sugar packet feeding device 3, a cup body feeding device 4, and a pressing device 6 arranged in sequence around the assembly table 1 in a clockwise or counterclockwise direction And turning device 5; And the unloading device 7 that is arranged on the output end of turning device 5.

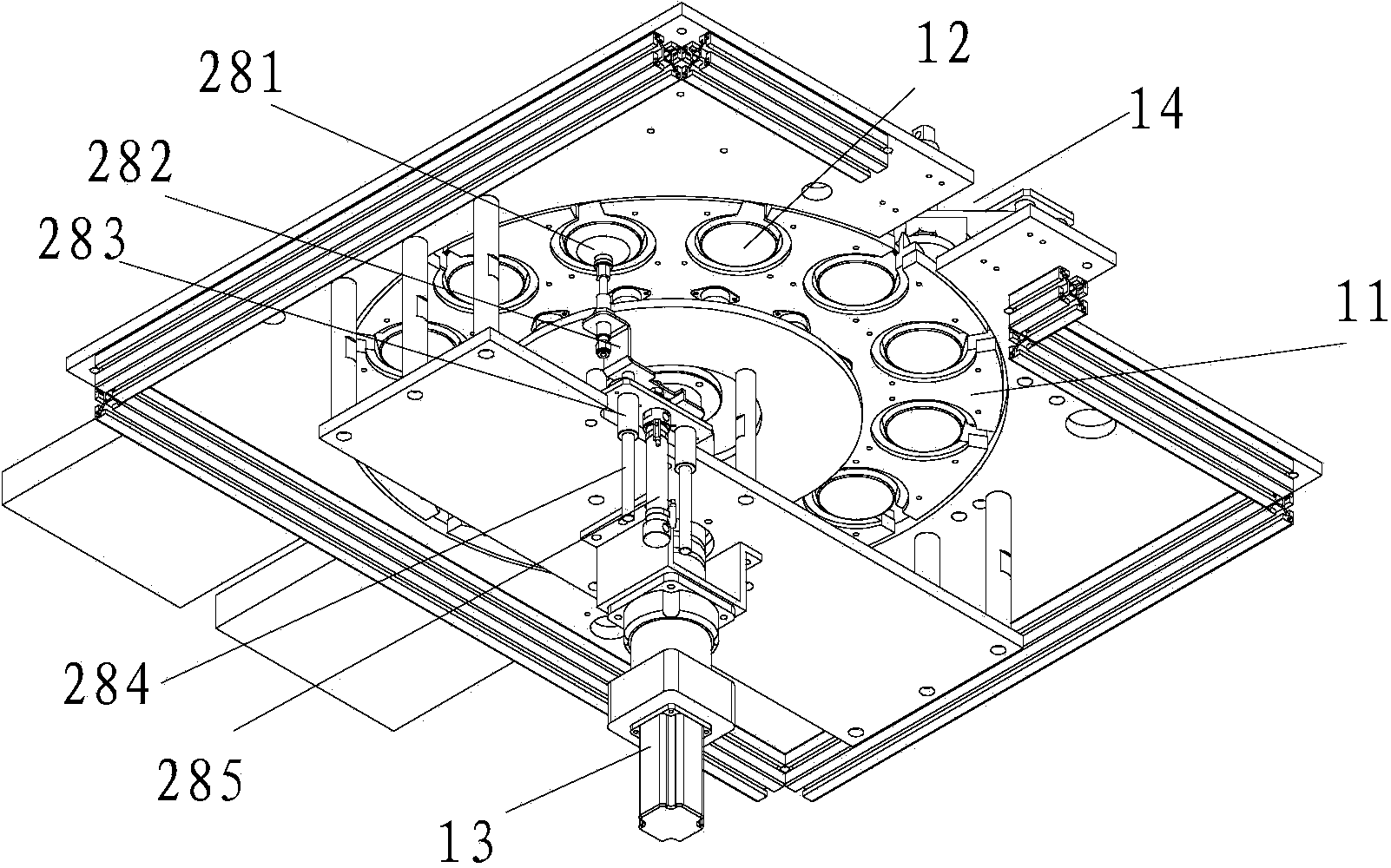

[0045] The structure of assembly table 1 is as follows image 3 As shown, the assembly platform 1 includes a rotatable rotary platform 11; on the rotary platform 11 there are several work stations 12 distributed along the circumference. The working station 12 is provided with an accommodation cavity for accommodating the cover body; the rotating platform 11 is rotated by assembling an indexing drive motor 13 .

[0046] The cover feeding device 2 includes ...

Embodiment 2

[0064] Guiling jelly assembly equipment in this embodiment includes a control device and an assembly platform, and a cover feeding device, a sugar bag feeding device, a cup body feeding device, a press-down device, and a cover body feeding device that are sequentially arranged around the assembly table in a clockwise or counterclockwise direction. device and turning device;

[0065] The assembly platform includes a rotatable rotating platform; the rotating platform is provided with a number of stations distributed along the circumference; the cover feeding device includes a cover outlet; the sugar bag feeding device includes a sugar bag outlet; the cup feeding device includes a cup body Outlet; the outlet of the cover body, the outlet of the sugar bag and the outlet of the cup body correspond to the position of the station respectively, so that the cover body, the bag of sugar and the cup body can be loaded onto the station one by one;

[0066] The pressing device includes a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com