Strip steel shot blaster

A shot blasting machine and strip steel technology, applied in abrasive jet machine tools, grinding/polishing equipment, used abrasive treatment devices, etc., can solve problems such as low work efficiency, residual rust in strip steel, and poor treatment effect. , to achieve good cleaning effect and good shot blasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

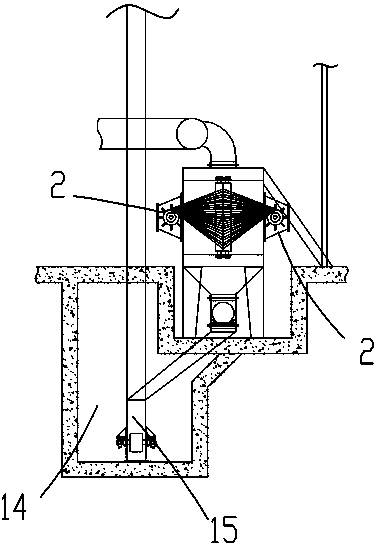

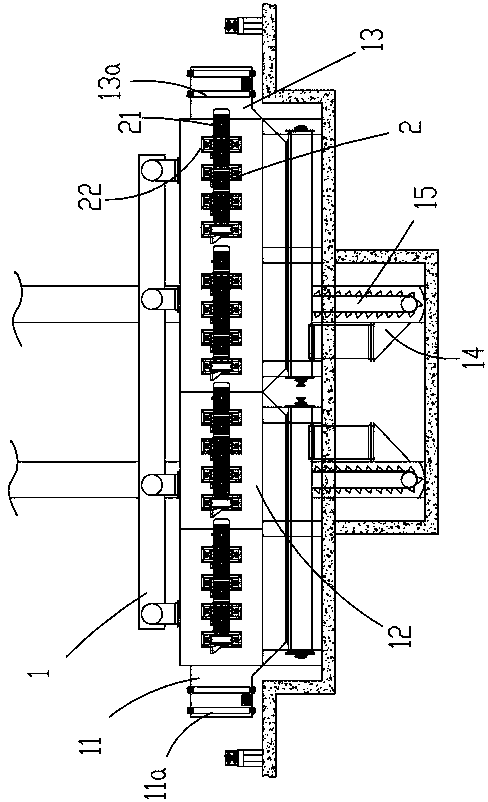

[0019] Figure 1 to Figure 2 Shown is the structural representation of the present invention.

[0020] The reference signs therein are: machine base 1, strip steel entrance 11, entrance conveying roller 11a, shot blasting chamber 12, strip steel exit 13, exit conveying roller 13a, steel shot storage tank 14, hoist 15, blasting device 2 , pill motor 21, centrifugal cylinder 22.

[0021] Such as Figure 1 to Figure 2 Shown, a kind of strip steel shot blasting machine of the present invention comprises support 1, and support 1 is provided with the strip steel inlet 11 that connects successively, shot blast chamber 12 and strip steel outlet 13, and strip steel entrance 11 and shot blasting Between the chambers 12, a front auxiliary room and a rear auxiliary room to prevent steel shots from splashing are provided, and a steel shot storage tank 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com