Gluten-free instant ramen and its preparation method and recipe

A gluten-free and noodle-pulling technology, which is applied in food heat treatment, food ingredients as taste improvers, functions of food ingredients, etc., can solve problems such as being unable to satisfy people with gluten protein allergies, achieve fine and smooth taste, and reduce sewage discharge , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

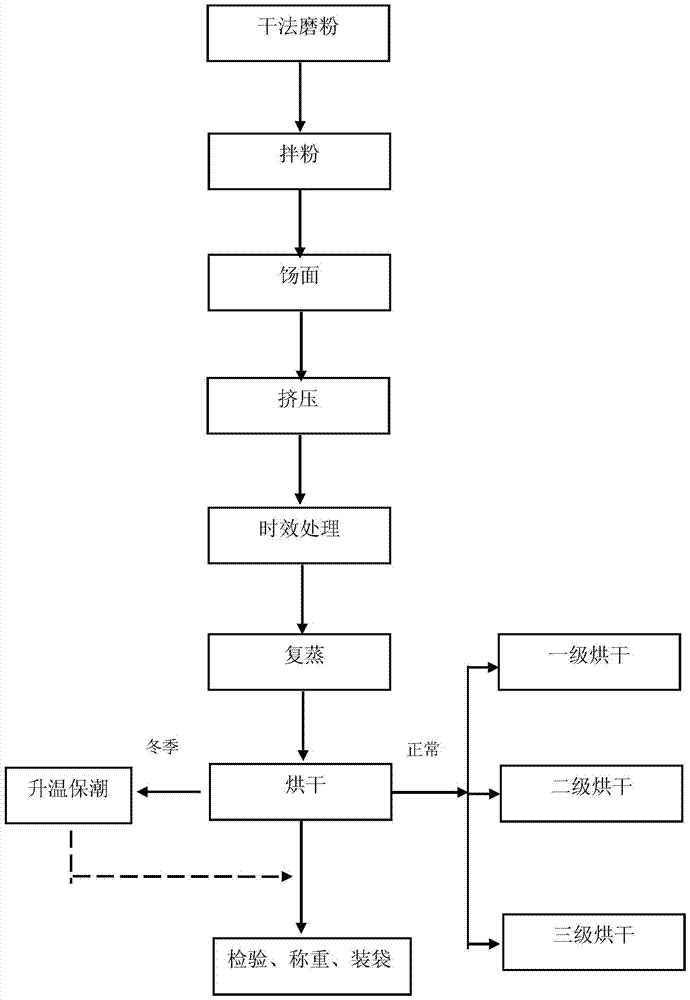

Method used

Image

Examples

Embodiment 1

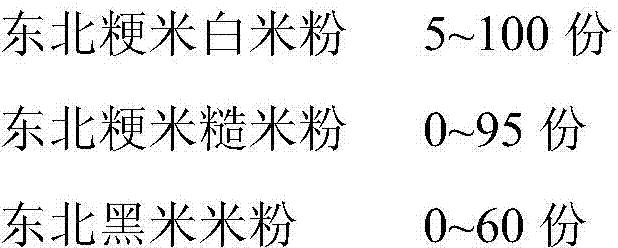

[0059] Raw material formula of white rice ramen: 100 parts of northeast japonica white rice noodles;

[0060] (1) Dry milling: take 100 parts of Northeast japonica rice white rice flour according to the required raw material ratio, sieve to remove impurities, and obtain a dry powder with a specification of more than 80 mesh; the specification of the dry powder is preferably 100 to 180 mesh;

[0061] (2) Powder mixing: mix the dry powder obtained in step (1) with 30 parts of pure water, and use a powder mixing machine to mix the powder until the powder is evenly mixed;

[0062] (3) Noodles: After mixing the flour, mix the noodles for 10 to 40 minutes to get noodles;

[0063] (4) Extrusion: Put the powder noodles into the feed port of the screw extruder to perform primary extrusion and secondary extrusion in sequence;

[0064] The first-stage extrusion is that when the central temperature of the extruder is 130° C., the noodles pass through the extrusion cavity and are extruded...

Embodiment 2

[0076] Raw material formula of brown rice ramen: 80-95 parts of Northeast Japonica rice brown rice flour, 5-20 parts of Northeast Japonica rice white rice flour;

[0077] Compared with Example 1, only the drying conditions are different in this embodiment, and the specific methods are as follows:

[0078] (1) Dry milling: take by weighing 80 parts of Northeast japonica rice brown rice flour and 20 parts of Northeast japonica rice white rice flour according to the required raw material ratio, sieve to remove impurities, and get a dry powder with a specification of more than 80 mesh; the dry powder specification is preferably 100-180 mesh;

[0079] (2) Powder mixing: mix the dry powder obtained in step (1) with 30 parts of pure water, and use a powder mixing machine to mix the powder until the powder is evenly mixed;

[0080] (3) Noodles: After mixing the flour, mix the noodles for 10 to 40 minutes to get noodles;

[0081] (4) Extrusion: Put the powder noodles into the feed po...

Embodiment 3

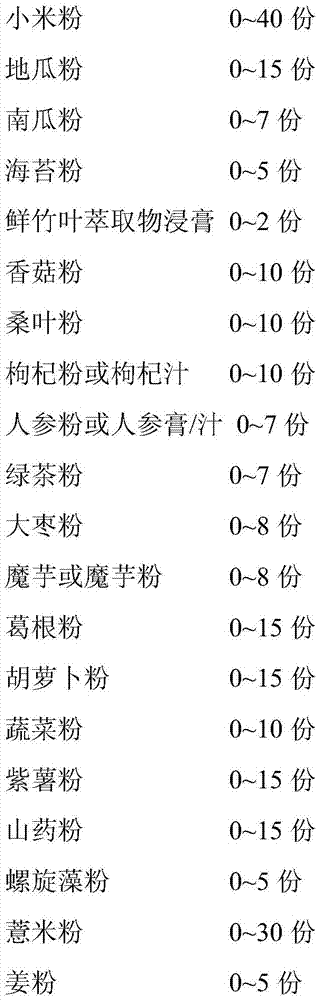

[0094] The following recipes all adopt the method of this embodiment to prepare gluten-free instant ramen:

[0095] Raw material formula of black rice ramen: 40-60 parts of northeast black rice noodles, 5-20 parts of northeast japonica rice white rice noodles, 40-60 parts of northeast japonica rice brown rice noodles;

[0096] Raw material formula of millet ramen: 30-40 parts of millet flour, 10-15 parts of Northeast japonica rice white rice noodles, 40-50 parts of Northeast japonica rice brown rice noodles;

[0097] Take the raw material formula of black rice hand-pulled noodles as example below, further illustrate, and present embodiment is compared with embodiment 1, and only drying condition is different, and concrete method is as follows:

[0098] (1) Dry milling: take by weighing 60 parts of northeast black rice flour, 20 parts of northeast japonica rice white rice flour, and 40 parts of northeast japonica rice brown rice flour according to the required raw material rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com