Sealing assembly for sealing a reciprocating piston rod of a reciprocating compressor

A sealing system, reciprocating piston technology, applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve problems such as weakening the function of the sealing system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

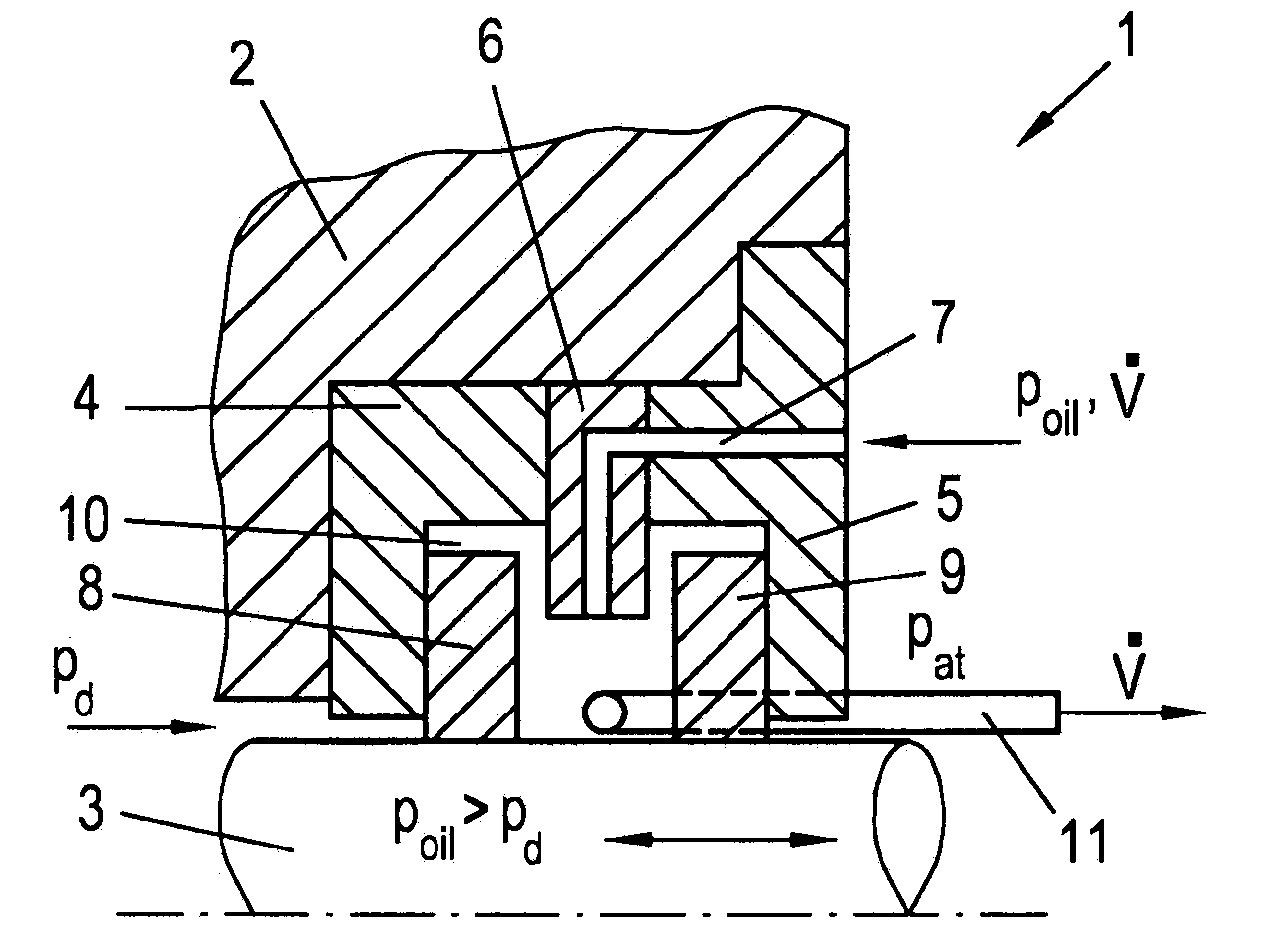

[0024] in figure 1 Shows a known sealing system 1 for the pressure to be sealed relative to the working medium p d For example, the cylinder pressure seals the axially reciprocating piston rod 3 of a piston compressor. The sealing system 1 is arranged in a fixed housing part 2 of the compressor, such as a compressor housing, and seals between the housing part 2 and the moving piston rod 3. The sealing system 1 is installed in a preassembled state, for example, as is sufficiently known, and is fixed in the housing part 2 for example by means of a plurality of bolts distributed on the circumference. In the illustrated example, the sealing system 1 includes two L-shaped chamber disks 4, 5, which are axially separated by a partition disk 6 in the illustrated embodiment. Naturally, other implementation structures such as T-shaped partition discs are also conceivable. A flange can also be provided on the cavity disc 5 on the outside in the radial direction, by means of which the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com