Ultra-large-section fanlike split conductor

A technology for dividing conductors and sector conductors, applied in conductors, insulated conductors, insulated cables, etc., can solve the problems of reducing insulation performance, surface unevenness, increasing line loss, etc., to increase conductor cross-section, improve transmission capacity, and not loose Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

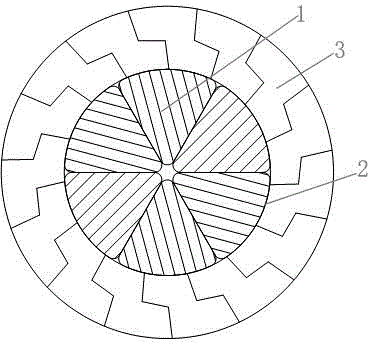

[0015] Such as figure 1 A super-large cross-section fan-shaped split conductor is shown, the conductor center is formed by a collection of six split fan-shaped conductor strands 1; the entire collection of split fan-shaped conductor strands 1 is stranded with a conductor single wire layer 3; the described An isolated insulating crepe paper 2 is arranged between the assembled sector-shaped conductor strands 1 and the stranded conductor single wire layer 3; the conductor single wire layer 3 is a Z-shaped single wire layer.

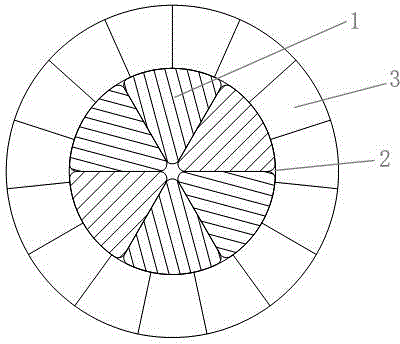

[0016] Such as figure 2 shown, with figure 1 The difference is that the conductor single wire layer 3 is a tile-shaped single wire layer.

[0017] There are many specific application approaches of the present invention, and the above description is only a preferred embodiment of the present invention. It should be pointed out that for those of ordinar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Section | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com