Freezing scanning electron microscope test method for nanoparticles in cosmetics

An electron microscope and detection method technology, applied in the field of testing, can solve problems such as deterioration, identification technology and lack of certification parties, agglomeration, etc., to achieve the effect of improving detection efficiency, shortening preparation time, and avoiding agglomeration and denaturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

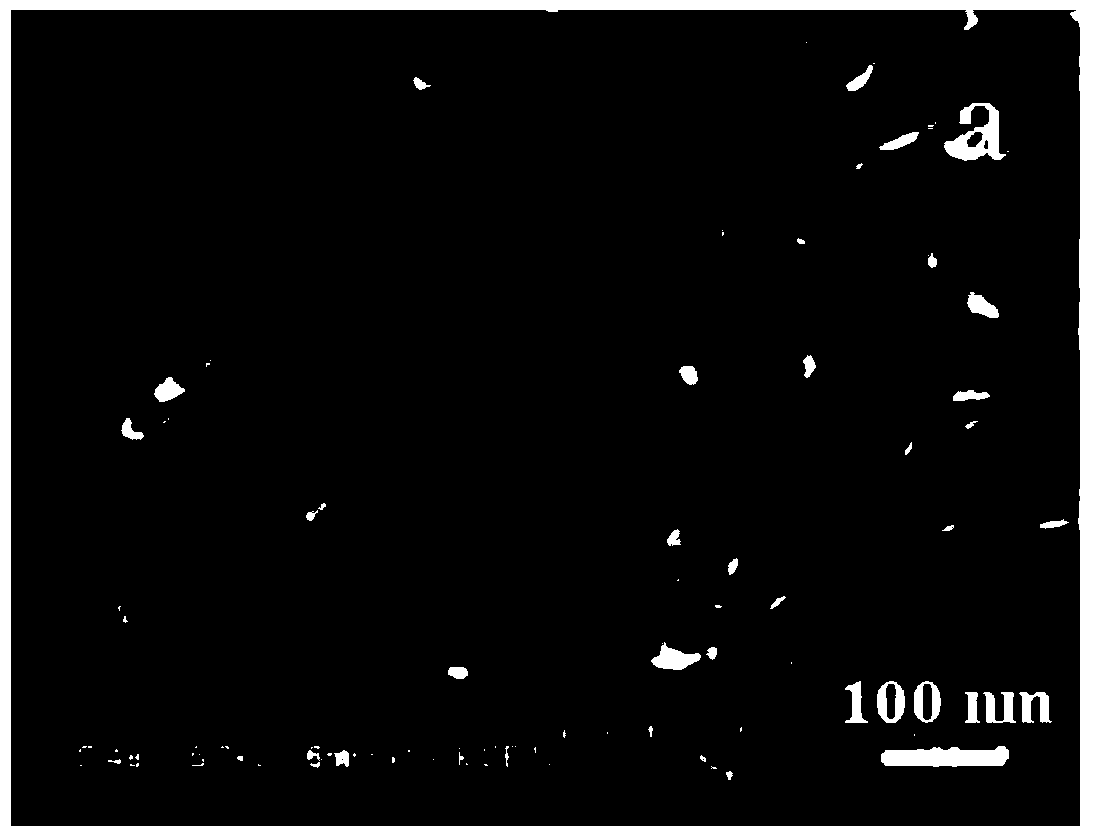

[0028] Example 1: Detection of Nanoparticles in Sunscreen

[0029] Take an appropriate amount of sunscreen sample and apply it in the groove of the sample holder with a thickness of 0.1mm to keep the sample holder in a horizontal state, put it into a freezer and freeze it for 20 minutes, transfer it to a sputtering instrument with a temperature of -112°C in the sample chamber, and coat it with a platinum film 60s, and then transferred to a scanning electron microscope with a sample chamber temperature of -106°C with a cryotransfer device for morphology testing, with a magnification of 30k, and EDS testing for the observed nanoparticles. From figure 1 It can be seen that there are needle-shaped nanoparticles in the sunscreen, with a length of about 80nm and a diameter of about 20nm. SEM observation showed that the nanoparticles were not agglomerated and distributed evenly.

[0030] As a comparison, the elemental composition of the sample was tested by traditional ICP (Inducti...

Embodiment 2

[0036] The detection of nanoparticle in embodiment 2 segregation cream

[0037] Take the isolation frost sample and apply it in the groove of the sample holder with a thickness of 0.1mm to keep the sample holder in a horizontal state, put it into the freezer and freeze it for 20 minutes, and transfer it to the sputtering instrument with the temperature of the sample chamber at -111°C with the frozen transfer device , gold-plated film for 60s, and then transferred to a scanning electron microscope with a sample chamber temperature of -105°C using a cryotransfer device for morphology testing, with a magnification of 100k, and EDS testing for the observed nanoparticles. From figure 2 It can be seen that there are spherical nanoparticles in sunscreen with a diameter of about 10nm. It can be seen from Table 2 that the composition of nanoparticles is SiO 2 , The quantitative detection results of EDS were consistent with the results of traditional ICP.

[0038] The composition an...

Embodiment 3

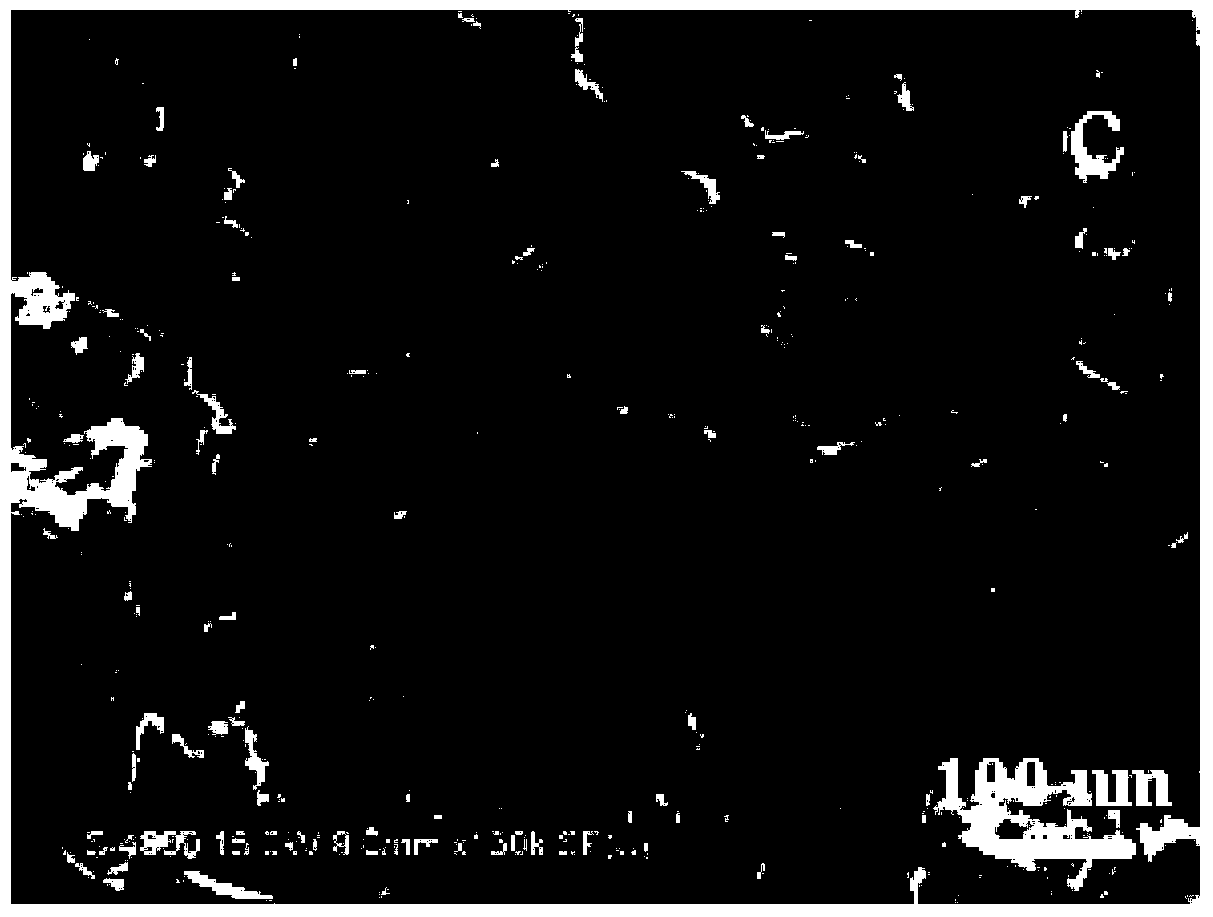

[0040] The detection of nanoparticle in embodiment 3 repairing face cream

[0041] Take an appropriate amount of repairing cream sample and apply it in the groove of the sample holder, the thickness is 0.1mm, so that the sample holder is kept in a horizontal state, put it into the freezer and freeze it for 20 minutes, transfer it to the sample chamber with a frozen transfer device at a temperature of -114°C for sputtering In the instrument, the film was coated for 60 s, and then transferred to a scanning electron microscope with a sample chamber temperature of -106°C by a cryotransfer device for morphology testing, with a magnification of 30k, and EDS testing was performed on the observed nanoparticles. From image 3 It can be seen that there are rod-shaped nanoparticles in the sunscreen, the length is about 60nm, and the diameter is about 30nm. It can be seen from Table 3 that the composition of nanoparticles is ZnO, and the quantitative detection results of EDS are consiste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com