Radix ophiopogonis drying device

A technology of drying device and Ophiopogon japonicus, which is applied in the directions of drying gas arrangement, drying, drying machine, etc., to achieve the effect of protecting quality, protecting electric heating device and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

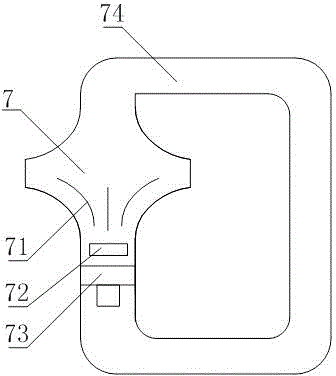

[0024] Such as figure 1 with figure 2 Shown, a kind of Ophiopogon japonicus drying device comprises frame 2, and described frame 2 is provided with conveying system 3, and conveying system 3 comprises at least two belt pulleys 4 and the endless conveyer belt that are fixed on frame 2 5. The axes of the pulleys 4 are parallel to each other, and the conveyor belt 5 is wound between the pulleys 4. A heat source cavity 7 is also arranged in the hollow area of the conveyor belt 5, and the heat source cavity 7 is connected to a hot air circulation system;

[0025] The hot air circulation system includes a circulation pipeline 74, an electric heating device 72 and an axial flow fan 73. The circulation pipeline 74 and the heat source chamber 7 form a closed air circulation annular pipeline, and the electric heating device 72 and the axial flow fan 73 are arranged on In the air circulation ring pipe;

[0026] The frame 2 is also provided with a feed port 9 and a discharge port 1 r...

Embodiment 2

[0029] The present embodiment is further limited on the basis of embodiment 1, as figure 1 with figure 2 As shown, in order to make Ophiopogon japonicus have a longer heating time during the transmission process, the heat source chamber 7 is a cuboid rectangular tube, and the width direction of the heat source chamber 7 is parallel to the width direction of the conveyor belt 5 . The above structure facilitates setting the heat source cavity 7 close to the conveyor belt 5 to enhance the heat transfer gradient. At the same time, as a preference, the width of the heat source cavity 7 is set to be close to the width of the conveyor belt 5, and the length of the heat source cavity 7 is set to be slightly shorter than that covered with wheat. The length of the conveyor belt 5 of the winter can make the Ophiopogon japonicus evenly and efficiently roasted during the conveying process.

[0030] In order to facilitate the manufacture of the present invention and improve the uniformity...

Embodiment 3

[0035] This embodiment is further limited on the basis of the above embodiments, as figure 1 with figure 2 As shown, in order to protect the air circulation annular pipe, the axial flow fan 73 and the electric heating device 72, and facilitate the automatic control of the upper limit of the temperature of the heat source cavity 7, a temperature sensor and a pressure equalizing valve are also arranged in the air circulation annular pipe. The output end of the temperature sensor is connected to the control circuit of the electric heating device 72 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com