Alarm Drill Pipe for Horizontal Directional Drilling Rig Drilling

A technology for horizontal directional drilling rigs and drill pipes, applied in directional drilling, drill pipes, drill pipes, etc., to achieve the effects of easy implementation, reduced construction costs, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

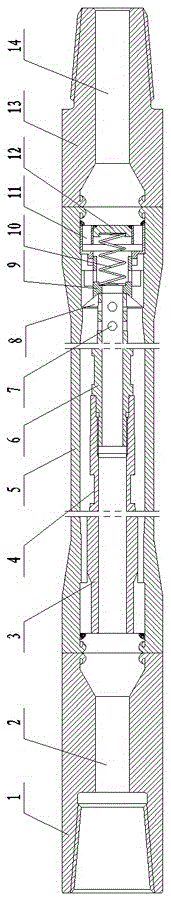

[0010] An alarm drill pipe for drilling with a horizontal directional drilling rig, comprising a drill pipe body 5, a female joint 1 is fixed at the rear end of the drill pipe body 5, and a flushing liquid inlet chamber 2 is arranged inside the female joint 1, and a flushing liquid inlet chamber 2 is arranged inside the drill pipe body 5. The front end of 5 is fixed with a male joint 13, and the inside of the male joint 13 is provided with a flushing liquid outlet chamber 14, which is characterized in that: a hollow straight rod body parallel to the axial direction of the drill pipe body is provided inside the drill pipe body 5, and the hollow straight The rear part of the rod body is provided with a centering boss that cooperates with the inner wall of the drill pipe body, and a positioning stop that cooperates with the centering boss is provided on the inner wall of the drill pipe body. The inner cavity of the hollow straight rod body is set as The flushing liquid channel I c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com