In the sand soil, the core method of drilling the core of the rocky core is used in the sand soil

A sandy soil and core technology, applied in the field of sandy soil core sample collection, can solve the problem that it is difficult to accurately determine the particle composition of sandy soil core samples, which affects the accuracy of sandy soil layering and geological identification, and the drilling and extraction of sandy soil layers. Low core rate and other issues, to achieve the effect of being conducive to widespread application, easy to learn and master, and low equipment performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

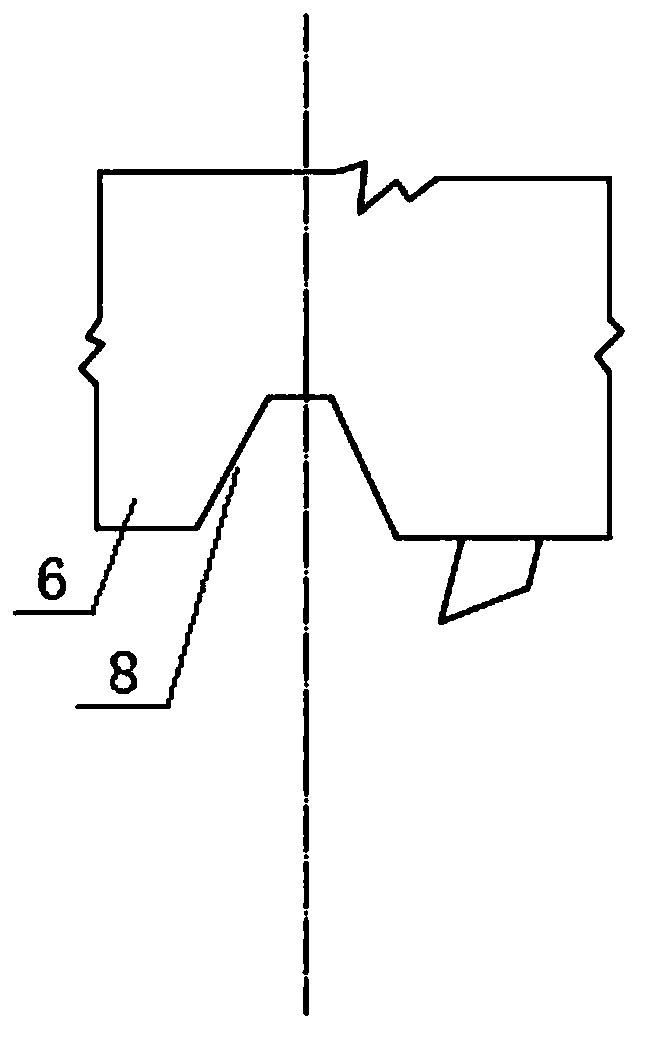

Image

Examples

Embodiment 1

[0061] In the deep sand layer of a certain river, adopt the drilling and coring method of adopting the mud coat to wrap the core in the sand according to the present invention to drill and take the core, comprising the following steps:

[0062] Step 1: Drilling equipment is in place and assembled;

[0063] Step 2: Prepare natural composite mud according to the distribution of strata;

[0064] Natural composite mud is composed of water, bentonite, PW dry powder, and NaOH; bentonite: PW dry powder: NaOH is equal to 100:25:1.0:0.75; the mud specific gravity of natural composite mud is 1.03g / cm 3 ;The mud viscosity of natural composite mud is 18s;

[0065] Step 3: Drilling and coring: The diameter of the alloy drill bit of the drilling equipment is 110mm, and 9 alloy bits are inlaid with welded alloy;

[0066] (1) Drilling, according to the type of stratum, the drilling equipment drills according to the corresponding drilling parameters to a footage of 1.50m; each time the foota...

Embodiment 2

[0079] In the deep sand layer of a certain river, adopt the drilling and coring method of adopting the mud coat to wrap the core in the sand according to the present invention to drill and take the core, comprising the following steps:

[0080] Step 1: Drilling equipment is in place and assembled;

[0081] Step 2: Prepare natural composite mud according to the distribution of strata;

[0082] Natural composite mud is composed of water, bentonite, PW dry powder, and NaOH; water: bentonite: PW dry powder: NaOH is equal to 100:35:1.0:0.6; the mud specific gravity of natural composite mud is 1.15g / cm 3 ;The mud viscosity of natural composite mud is 21s;

[0083] Step 3: Drilling and coring: The diameter of the alloy drill bit of the drilling equipment is 110mm, and 9 alloy bits are inlaid with welded alloy;

[0084] (1) Drilling, according to the type of stratum, the drilling equipment drills according to the corresponding drilling parameters to a footage of 1.50m; each time the...

Embodiment 3

[0097] In the deep sand layer of a certain river, adopt the drilling and coring method of adopting the mud coat to wrap the core in the sand according to the present invention to drill and take the core, comprising the following steps:

[0098] Step 1: Drilling equipment is in place and assembled;

[0099] Step 2: Prepare natural composite mud according to the distribution of strata;

[0100] Natural composite mud is composed of water, bentonite, PW dry powder, and NaOH; bentonite: PW dry powder: NaOH is equal to 100:30:1.0:0.75; the mud specific gravity of natural composite mud is 1.10g / cm 3 ;The mud viscosity of natural composite mud is 19s;

[0101] Step 3: Drilling and coring: The diameter of the alloy drill bit of the drilling equipment is 110mm, and 9 alloy bits are inlaid with welded alloy;

[0102] (1) Drilling, according to the type of stratum, the drilling equipment drills according to the corresponding drilling parameters to a footage of 1.50m; each time the foota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com