Water-jacket type reverse microcirculation guiding coring device

A water-proof micro-reverse circulation technology, which is applied in the extraction of undisturbed core devices, wellbore/well components, and earth-moving drilling and mining, etc. Improve efficiency and optimize the effect of storage space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with specific embodiment the present invention is described in further detail:

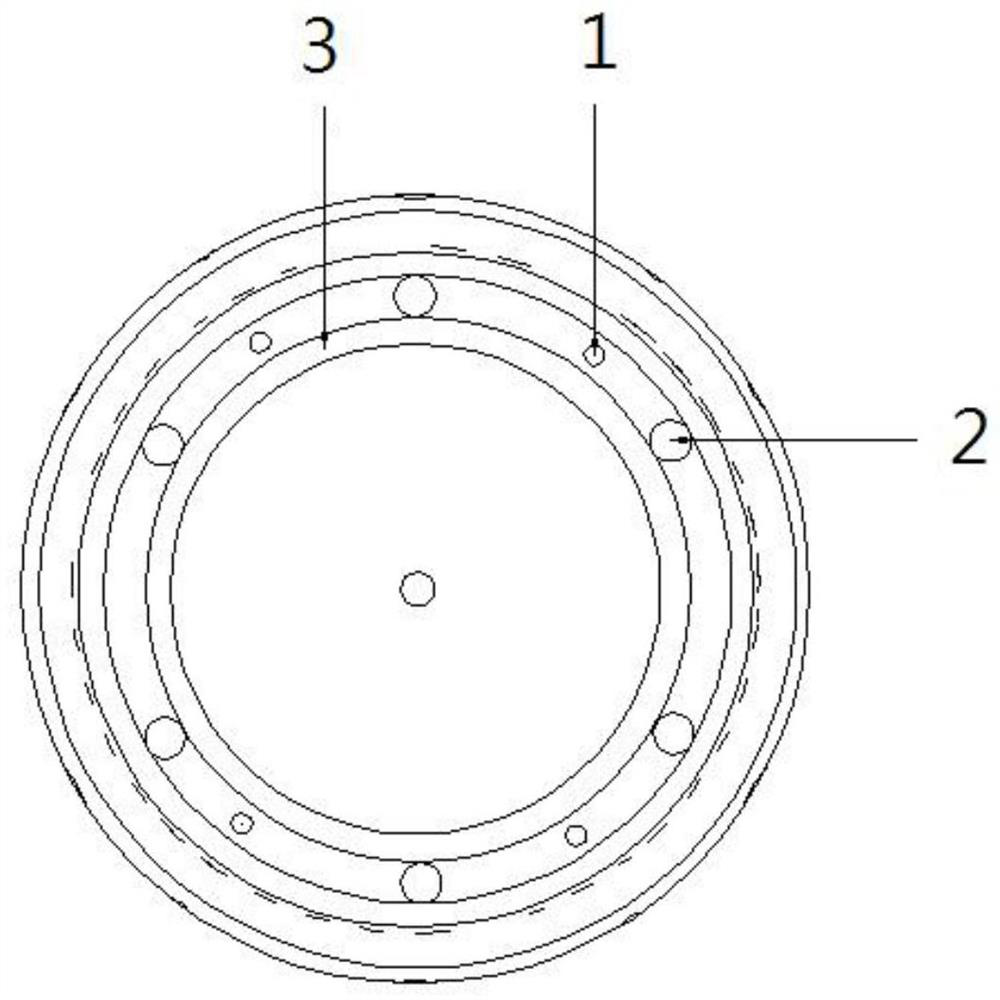

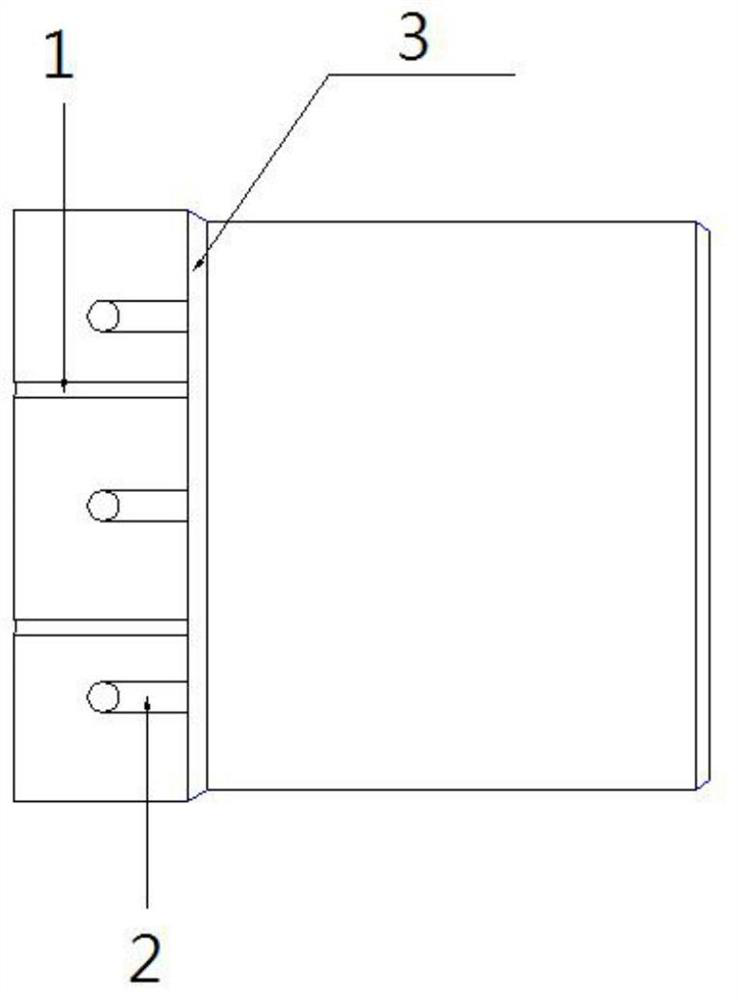

[0028] see figure 1 —6, the structure of the specific embodiment of the present invention includes a drill bit and a spring seat, the spring seat goes deep into the drill bit, the outer wall of the spring seat is slightly concave inward to form a through water groove 9, and one end of the drill bit is provided with a drill matrix 6 and a drill tire The body working layer 5, the drill matrix 6 and the drill matrix working layer 5 are provided with a direct water jet 7 and a side jet 4 communicating with the water tank 9, and the drill matrix 6 and the drill matrix working layer 5 are also provided with There are direct spray water tank 1 and side spray water tank 2.

[0029] The end of the bit matrix 6 connected to the spring seat is provided with a water-repellent and core guide step 3, and the inner side of the end connected to the bit matrix 6 is provided with a wedg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com