A method for separating indium and cadmium from indium and cadmium waste liquid

A technology for waste liquid, indium and cadmium, which is applied in the field of separation of indium and cadmium, can solve the problems of difficult solid-liquid separation, viscosity, poor operating conditions, etc., and achieves the effects of improving the type of sediment slag, improving the operating environment and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

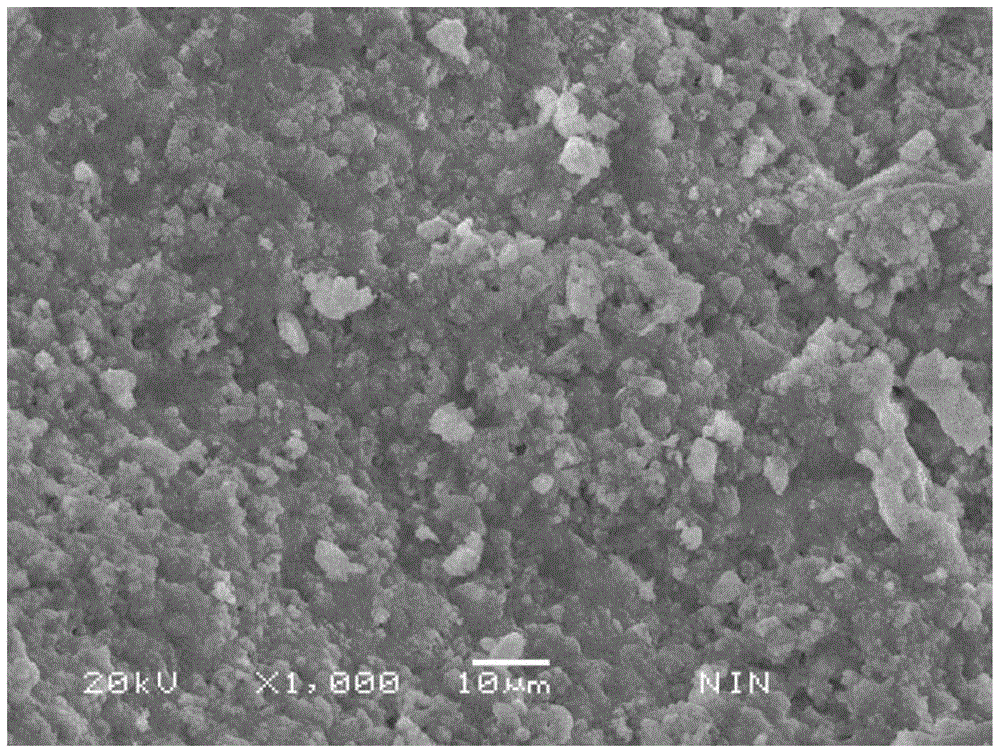

[0020] Step 1. Add 900 g of oxalic acid to 60 L of indium-cadmium waste liquid containing 7.5 g / L of indium and 2.5 g / L of cadmium, stir and react at room temperature with white precipitates, and continue stirring until the precipitates no longer increase;

[0021] Step 2, adding ammonia water to the indium cadmium waste liquid after the reaction in step 1 until the pH value of the indium cadmium waste liquid is 9, and standing and aging at room temperature for 12 hours;

[0022] Step 3, adopt the suction filtration method to carry out solid-liquid separation to the indium cadmium waste liquid after static aging in step 2, obtain filter cake and about 64L filtrate, filter cake weighs about 1.3kg after drying, to the dried The filter cake was analyzed and detected. The mass percentage of indium in the dried filter cake was 53.01%, and the mass percentage of cadmium was 0.96%. The filtrate was analyzed and detected, and the filtrate contained 1.2 mg / L of indium. Contains cadmium...

Embodiment 2

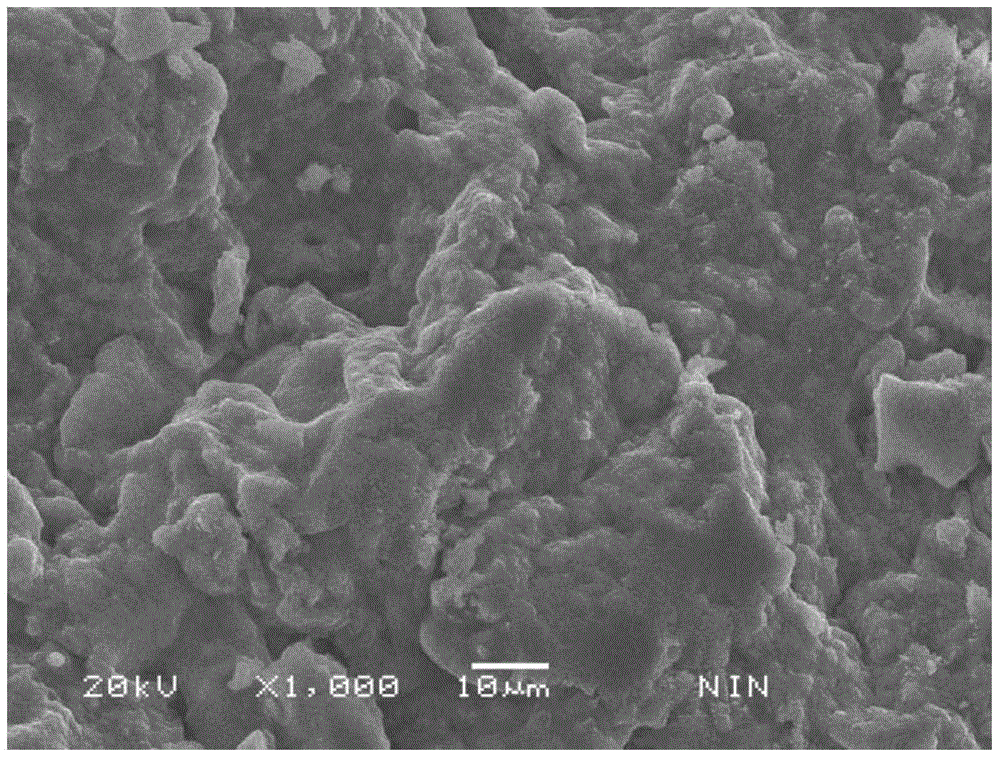

[0027] Step 1. Add 1200g of oxalic acid to 60L of indium-cadmium waste liquid containing 10g / L of indium and 3.4g / L of cadmium, stir and react at room temperature with white precipitates, and continue stirring until the precipitates no longer increase;

[0028] Step 2, adding ammonia water to the indium-cadmium waste liquid after the reaction in step 1 until the pH value of the indium-cadmium waste liquid is 9, and standing and aging at room temperature for 24 hours;

[0029] Step 3, adopt the suction filtration method to carry out solid-liquid separation to the indium cadmium waste liquid after static aging in step 2, obtain filter cake and about 65L filtrate, filter cake weighs about 1.5kg after drying, to the dried The filter cake was analyzed and detected. The mass percentage of indium in the dried filter cake was 68%, and the mass percentage of cadmium was 2.11%. The filtrate was analyzed and detected, and the filtrate contained 24mg / L of indium, containing Cadmium 3.0g / L...

Embodiment 3

[0034] Step 1. Add 1000 g of oxalic acid to 100 L of indium-cadmium waste liquid containing 5 g / L of indium and 1.7 g / L of cadmium. Stir and react at room temperature to form a white precipitate. Continue stirring until the precipitate does not increase;

[0035] Step 2, adding ammonia water to the indium cadmium waste liquid after the reaction in step 1 until the pH value of the indium cadmium waste liquid is 9, and standing and aging at room temperature for 15 hours;

[0036] Step 3, adopt the suction filtration method to carry out solid-liquid separation to the indium cadmium waste liquid after static aging in step 2, obtain filter cake and about 109L filtrate, filter cake weighs about 1.3kg after drying, to the dried The filter cake was analyzed and detected. The mass percentage of indium in the dried filter cake was 35%, and the mass percentage of cadmium was 1.46%. The filtrate was analyzed and detected, and the filtrate contained 1.7mg / L of indium. Contains cadmium 1.5g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com