Method for maintaining cellar by washing with hot water

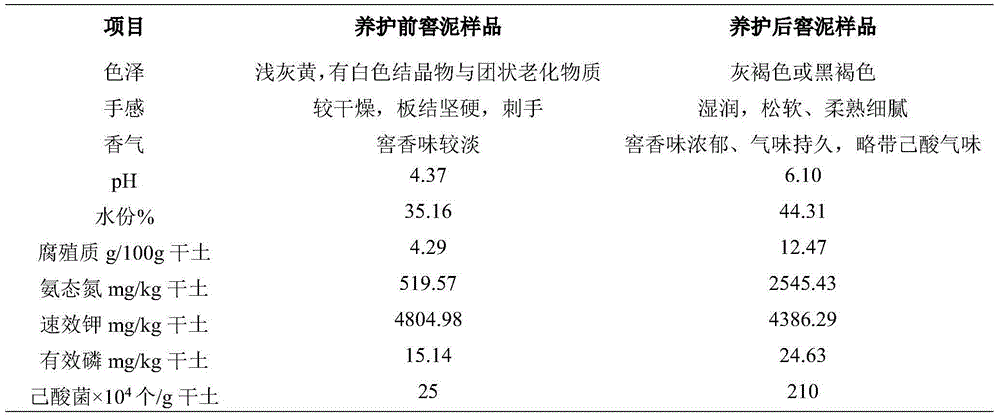

A technology of hot water washing and cellar, which is applied in the directions of biochemical equipment and methods, wine cellar appliances, etc., can solve the problems of cellar calcification, the calcification cell is not effectively controlled, and the water entering the cell is increased, so as to reduce cellar mud and other problems. Acidity, the appearance of pit mud is moist, and the effect of inhibiting calcification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 carries out cellar maintenance according to the following steps

[0029] (1) Clean the cellar wall and cellar bottom: After the wine unstrained spirits are cleaned, first clean the yellow water in the yellow water tank, and use a small broom to lightly sweep the cellar wall and the cellar bottom to ensure that there are no large pieces of bad grains attached, so that the subsequent sprinkling of fermented grains The powder and water can fully contact with the pit mud;

[0030] (2) Washing the cellar with hot water: After cleaning, use 15kg of 85°C hot water to slowly spray the cellar wall and cellar bottom with 15kg of 85°C hot water after cleaning, and rinse the residual unstrained spirits and lactate substances on the cellar wall , and finally clean up the sundries flowing into the small yellow water tank until it is clean; for the pond mouth with serious water shortage, follow this hot water washing method to raise the cellar until the second to third ro...

Embodiment 2

[0036] Embodiment 2 Carry out pit maintenance according to the following steps

[0037] (1) Clean the cellar wall and cellar bottom: After the wine unstrained spirits are cleaned, first clean the yellow water in the yellow water tank, and use a small broom to lightly sweep the cellar wall and the cellar bottom to ensure that there are no large pieces of bad grains attached, so that the subsequent sprinkling of fermented grains The powder and water can fully contact with the pit mud;

[0038] (2) Washing the cellar with hot water: After cleaning, use 12kg of hot water at 90°C to slowly spray the cellar wall and bottom of the cellar for the calcified cellar mud and the cellar mud with mold at the mouth of the pool. Rinse, and finally clean up the sundries flowing into the small yellow water tank until it is clean. For the pool mouth with serious water shortage, follow this hot water washing method to raise the cellar until the 2nd to 3rd row after resuming work;

[0039] (3) Ho...

Embodiment 3

[0044] Embodiment 3 Carry out pit maintenance according to the following steps

[0045] (1) Clean the cellar wall and cellar bottom: After the wine unstrained spirits are cleaned, first clean the yellow water in the yellow water tank, and use a small broom to lightly sweep the cellar wall and the cellar bottom to ensure that there are no large pieces of bad grains attached, so that the subsequent sprinkling of fermented grains The powder and water can fully contact with the pit mud;

[0046] (2) Washing the cellar with hot water: After cleaning, use 10kg of hot water at 95°C to slowly spray the cellar wall and bottom of the cellar for the calcified cellar mud and the cellar mud with mold at the mouth of the pool, and the residual unstrained spirits and white lactate substances on the cellar wall Rinse, and finally clean up the sundries flowing into the small yellow water tank until it is clean. For the pool mouth with serious water shortage, follow this hot water washing metho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com