Method for of producing bioorganic tobacco fertilizer by steam explosion technology

A bio-organic fertilizer and steam technology, applied in the preparation of organic fertilizers, organic fertilizers, bio-organic part treatment, etc., can solve the problems of unguaranteed product quality, large investment in equipment, serious secondary pollution, etc., and achieve disinfection procedures Reduce, increase production capacity, reduce the effect of fermentation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

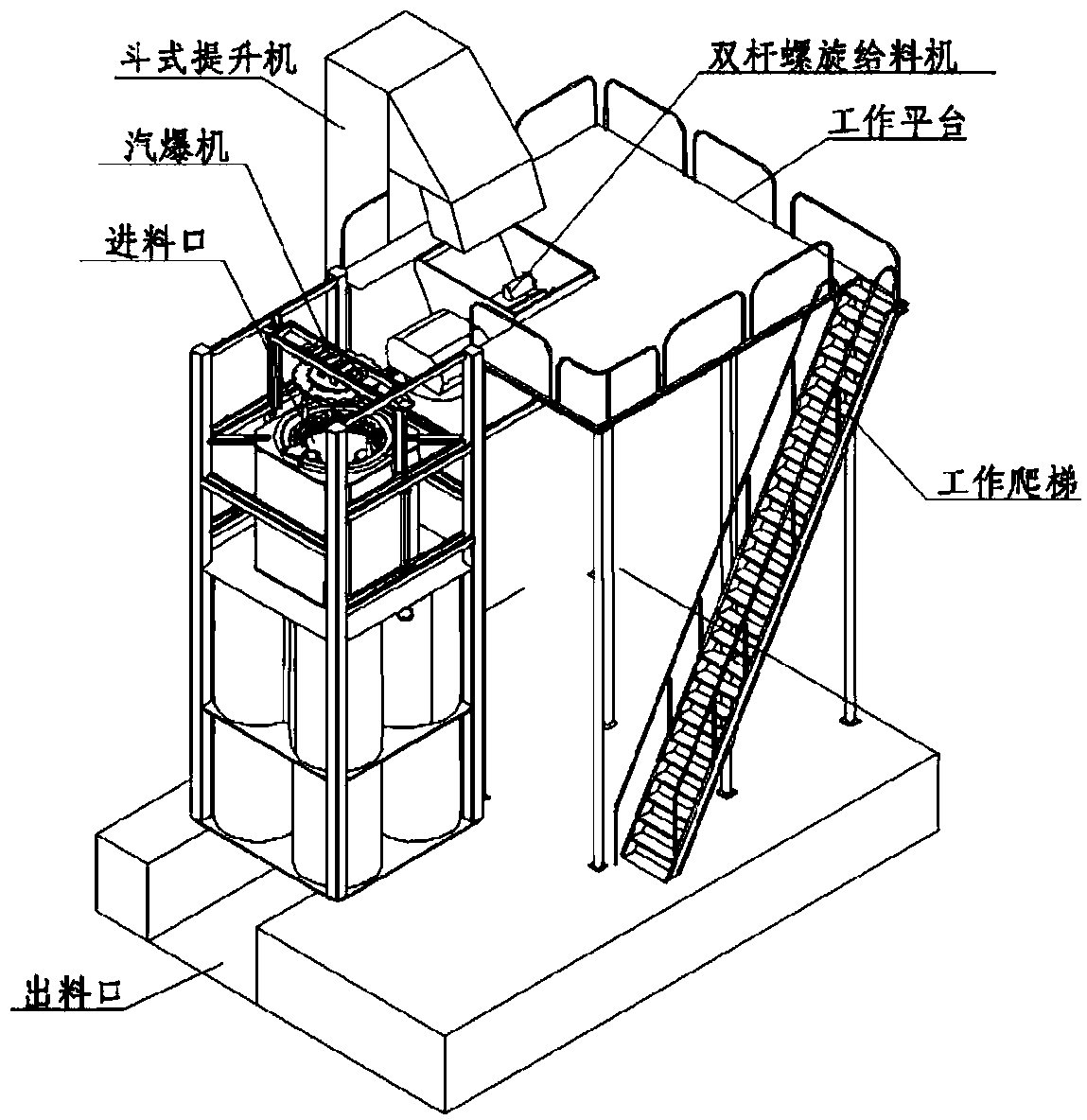

[0042] A method for producing tobacco bio-organic fertilizer by steam explosion technology, which is made according to the following steps:

[0043] a. Mechanical crushing of raw materials: crushing tobacco stalks, tobacco tendons, unsuitable tobacco leaves or other crop stalks;

[0044] b. Pressurized blasting: Put the crushed raw material particles in the above step into the steam blasting machine, when the temperature rises to 220°C-250°C, keep the pressure for 2-4 minutes, and start the blasting;

[0045] c. Adding strains: adding strains to the blasted raw material granules obtained in step b, adding cellulose-degrading fermentation bacteria, nicotine-degrading fermentation bacteria and lignin-degrading fermentation bacteria, potassium-degrading bacteria and selenium-degrading bacteria; Mix the raw material granules and strains evenly;

[0046] d. Fermentation: stack and ferment the raw material granules that are evenly mixed with the added strains on the fermentation fi...

Embodiment 2

[0050] A method for producing tobacco bio-organic fertilizer with steam explosion technology, characterized in that it is made according to the following steps:

[0051] a. Mechanical crushing of raw materials: crushing tobacco stalks, tobacco tendons, unsuitable tobacco leaves or other crop stalks to granules of ≤16mm, and keeping the water content of granules ≥10%;

[0052] b. Pressurized blasting: Put the crushed raw material particles in the above step into the pressure holding cylinder of the steam blasting machine, and pass in steam. When the temperature reaches 220°C, hold the pressure for 4 minutes, start the blasting switch, and the materials are ejected from the pressure holding cylinder Go outside the cylinder to complete the blasting process;

[0053] c. Add bacterial classification: add bacterial classification to raw material granule after the completion blasting of gained in step b, add cellulose degrading fermentation bacteria Bacillus licheniformis, Bacillus a...

Embodiment 3

[0057] A method for producing tobacco bio-organic fertilizer with steam explosion technology, characterized in that it is made according to the following steps:

[0058] a. Mechanical crushing of raw materials: crushing tobacco stalks, tobacco tendons, unsuitable tobacco leaves or other crop stalks to granules of ≤16mm, and keeping the water content of granules ≥10%;

[0059] b. Pressurized blasting: Put the crushed raw material particles in the above step into the pressure holding cylinder of the steam blasting machine, feed steam, when the temperature reaches 260°C, hold the pressure for 4 minutes, start the blasting switch, and the materials are ejected from the pressure holding cylinder Go outside the cylinder to complete the blasting process;

[0060] c. Add bacterial classification: add bacterial classification to raw material granule after the completion blasting of gained in step b, add cellulose degrading fermentation bacteria Bacillus licheniformis, Bacillus agave mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com