Dried Tofu Volume Meter

A metering and volumetric technology, which is applied in the direction of liquid materials, packaging, and packaging item types, can solve problems such as inability to complete automated operations, low production efficiency, and large measurement errors, and achieve broad market application prospects, improved safety, and improved efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

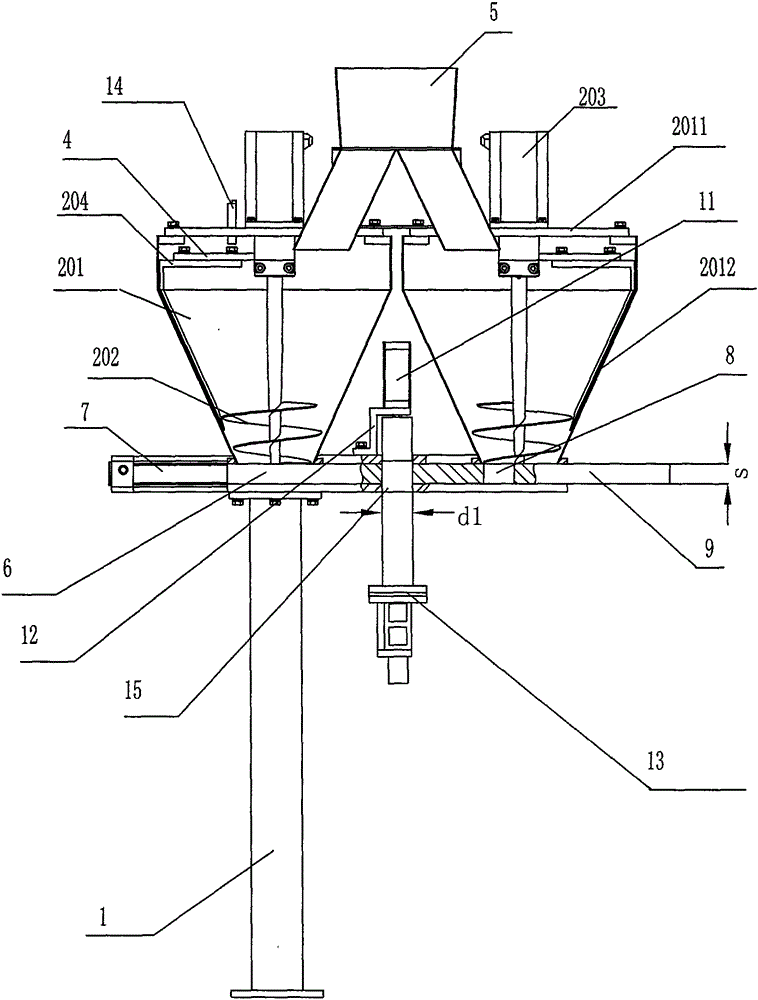

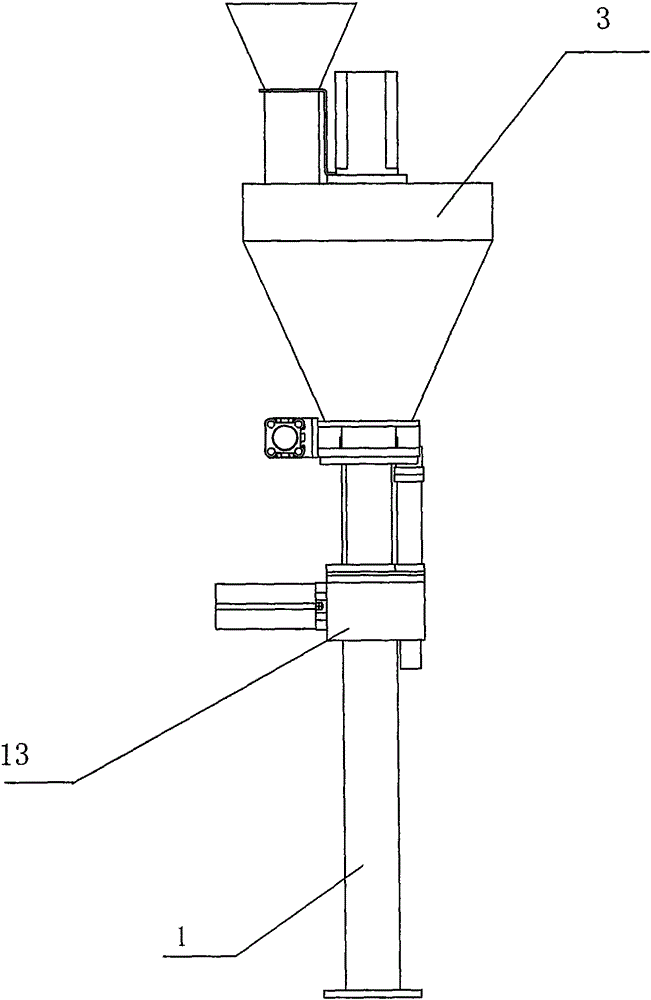

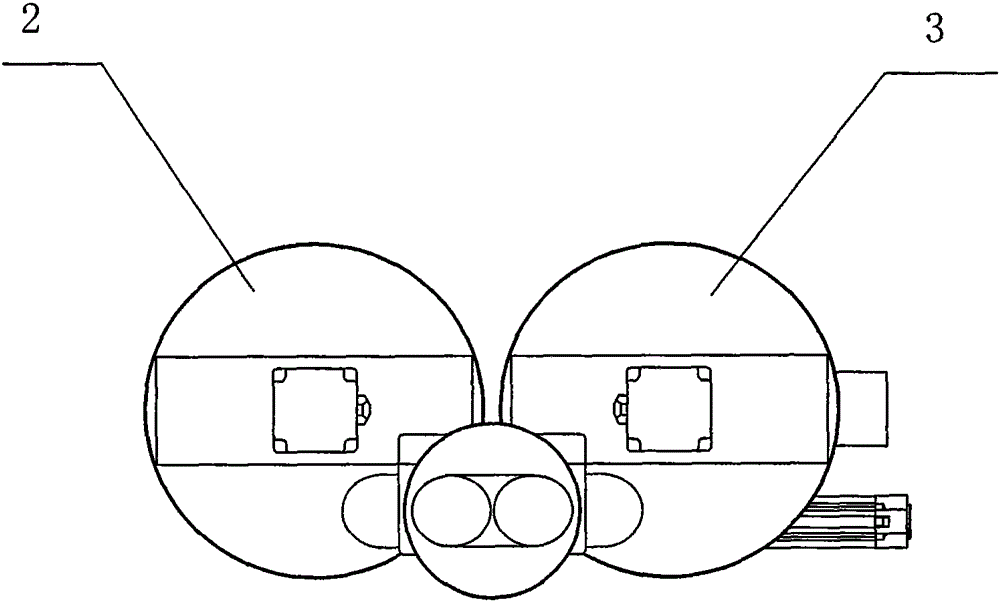

[0036] Such as Figure 1 to Figure 6 As shown, the dried tofu volume meter includes a photoelectric switch 14, a column 1, a left storage mixing system 2, a right storage mixing system 3, a lateral side plate 4, a feed splitter 5, a double-seat installation structure 6, and a push plate Cylinder 7, 2 measuring cups 8, measuring cup push plate 9, transverse connecting rod 10, punching cylinder A11, angle slats 12 and discharge refining forming system 13;

[0037]The left storage mixing system 2 or the right storage mixing system 3 includes a storage tank 201, a propeller 202, a stepper motor 203, and a stirring paddle 204; the storage tank 201 includes a storage tank upper cover 2011 and a storage tank The side wall 2012, the side wall 2012 of the storage tank is a downward conical surface; the propeller 202 is installed in the middle of the storage tank 201, and the propeller 202 takes advantage of the trend to drive the material to go in the downward direction of the propelle...

Embodiment 2

[0050] Such as Figure 1 to Figure 6 Shown, dried tofu volume meter. The diameter d1 is 70 mm, and the diameter d2 is 40 mm. The rest are the same as embodiment 1.

Embodiment 3

[0052] Such as Figure 1 to Figure 6 Shown, dried tofu volume meter. The diameter d1 is 80 mm, and the diameter d2 is 50 mm. The rest are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com