Anti-sniper rifle bullet composite glass

A composite glass and composite panel technology, which is applied in the direction of glass/slag layered products, protective clothing, protective equipment, etc., can solve the problem of bulletproof composite glass not being smashed, preventing violent terrorist attacks, insufficient critical places, and being unable to resist sniper rifle bullets Attack and other problems, achieve the effect of unit weight reduction and sound insulation performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

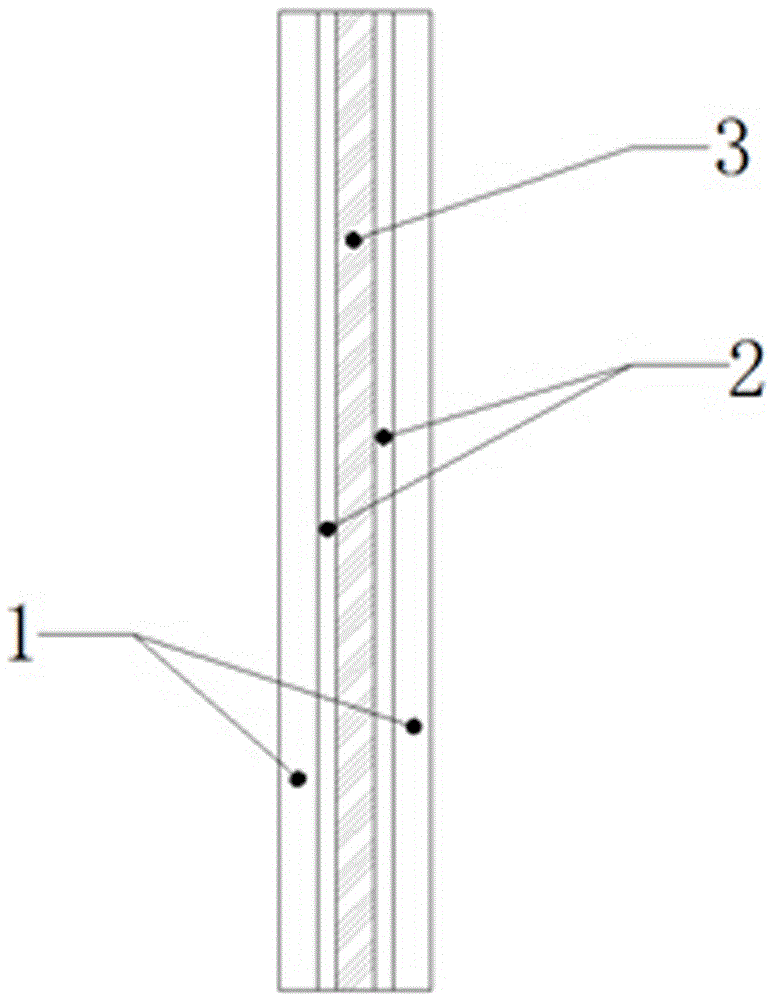

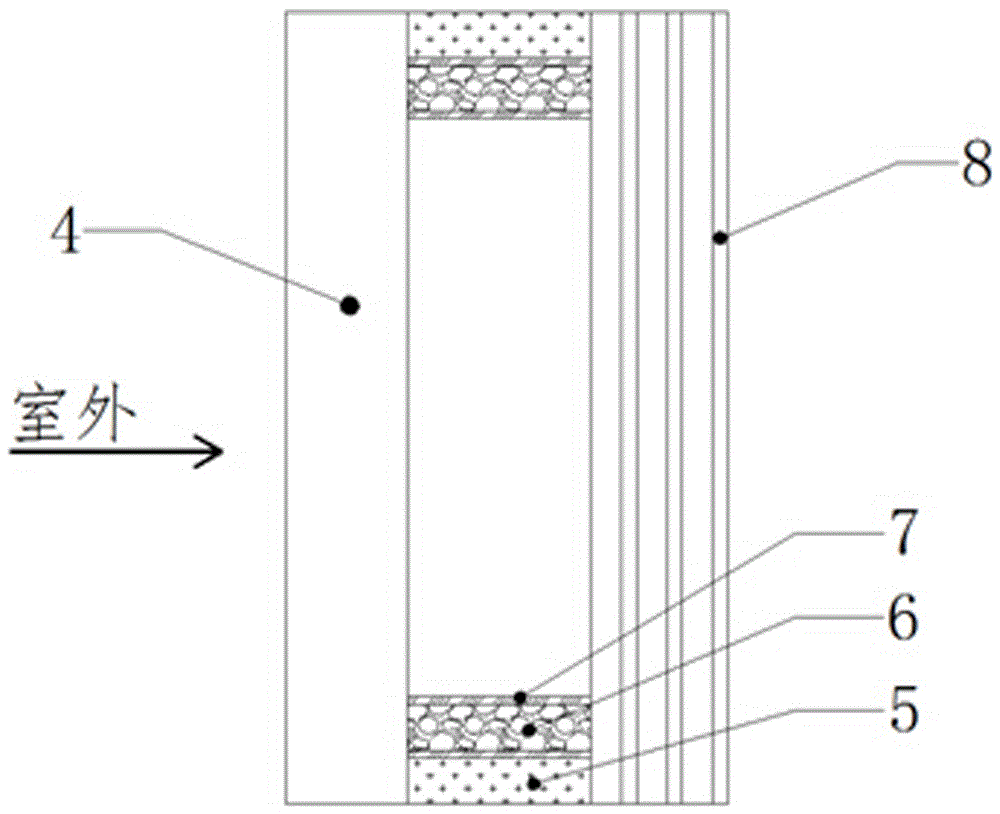

[0022] Such as figure 1 As shown, an anti-sniper rifle bullet composite glass disclosed in the present invention includes F79 bulletproof composite glass 4, float glass 1, transparent PC board 3, PU film 2, molecular sieve frame 7, molecular sieve 6, silicone sealant 5 , is characterized in that: a transparent PC board 3 is arranged between two pieces of float glass, and a PU film 2 is arranged between the float glass 1 and the transparent PC board 3 at the same time, the float glass 1, the transparent PC board 3 Between the PU film 2 is a plane-parallel overlapping composite structure, the plane-parallel overlapping composite structure is an anti-smashing transparent composite board with anti-smashing performance formed by heating and pressing to bond together, where the anti-smashing transparent composite board The plate and the F79 type bulletproof composite glass 4 are also arranged as a plane parallel overlapping composite structure, and a distance is set between the anti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com