Conical screw crusher

A crusher, cone technology, applied in the cone screw crusher. It can solve the problems of large space occupation, large volume, and the broken particles are not uniform enough, so as to achieve the effect of saving space, good secondary utilization, and prolonging the life of the machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

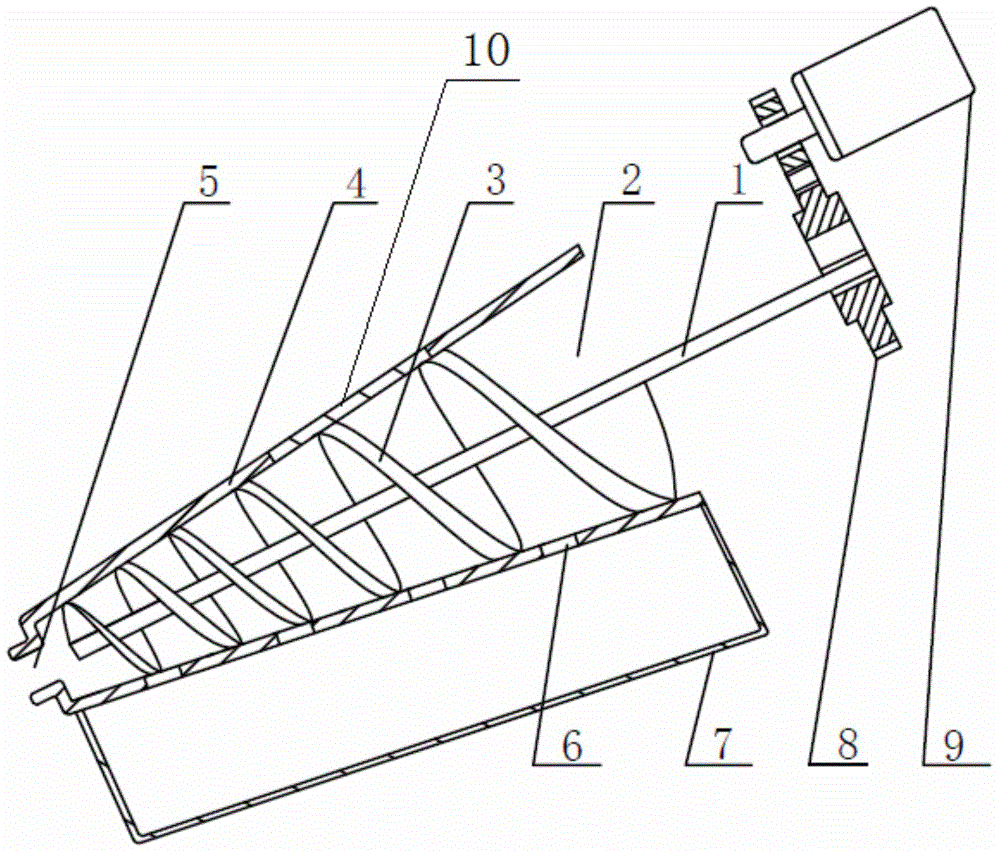

[0016] Such as figure 1 As shown, the conical screw crusher of the present invention includes a conical casing 4 installed obliquely, a main shaft 1, the main shaft 1 is installed in the conical casing 4, and a spiral fan blade 3 is fixed on the main shaft 1. The leaf 3 is close to the inner wall of the conical shell 4, the helical fan blade 3 has a helix with a certain taper, and the end of the main shaft 1 protruding from the conical shell 4 is equipped with a connecting gear 8, which is connected to the output shaft of the motor 9 The gears are meshed, the top of the conical shell 4 is provided with a material inlet 2, and a cover is provided at the material inlet 2, and the height of the material inlet is higher than the discharge port; the bottom of the conical shell 4 is provided with a discharge Port 5, a plurality of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com