Trace palladium nanoparticle for electrochemical catalysis ethanol oxidation, preparation method and application of trace palladium nanoparticle

A technology for palladium nanoparticles and ethanol oxidation, which can be applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., and can solve problems such as reducing the amount of palladium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

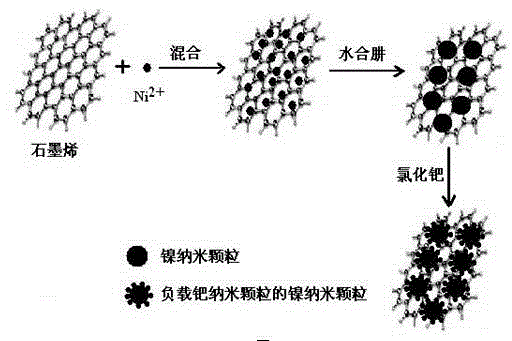

[0019] (1) 40 mg nickel chloride (NiCl 2 ·6H 2 O) Dissolved in 20 mL of ethylene glycol / water mixed solvent with a volume ratio of 1:1, then added 200 mg of graphene powder, and the mixture was o After ultrasonic dispersion in a water bath of C for 10 minutes, slowly add dilute NaOH solution to the mixture to adjust the pH of the mixture to 8-9; then continue to ultrasonically disperse the mixture for 1 hour to form nickel ions uniformly dispersed in the graphene Dispersion on the surface.

[0020] (2) Heat the above dispersion system in a water bath to 40 o C. Slowly add 6 mL of 5% hydrazine hydrate aqueous solution under continuous stirring. After the addition, continue to stir for 3 hours, filter while hot, wash with water until neutral, and then wash with ethanol twice, and the obtained black solid Immediately blow dry with nitrogen, then place in a vacuum oven, and dry at room temperature for 24 hours to obtain graphene-supported nickel nanoparticles.

[0021] (3)...

Embodiment 2

[0025] (1) 80 mg nickel chloride (NiCl 2 ·6H 2 O) Dissolved in 40 mL of ethylene glycol / water mixed solvent with a volume ratio of 1:1, then added 500 mg of graphene powder, and the mixture was o After ultrasonic dispersion in a water bath of C for 10 minutes, slowly add dilute NaOH solution to the mixture to adjust the pH of the mixture to 8-9; then continue to ultrasonically disperse the mixture for 1 hour to form nickel ions uniformly dispersed in the graphene Dispersion on the surface.

[0026] (2) Heat the above dispersion system in a water bath to 40 o C. Slowly add 11 mL of 5% hydrazine hydrate aqueous solution under continuous stirring. After the addition, continue to stir for 4 hours, filter while hot, wash with water until neutral, and then wash with ethanol twice. The obtained black solid Immediately blow dry with nitrogen, then place in a vacuum oven, and dry at room temperature for 24 hours to obtain graphene-supported nickel nanoparticles.

[0027] (3) Mi...

Embodiment 3

[0031] (1) Add 120 mg nickel chloride (NiCl 2 ·6H 2 O) Dissolved in 60 mL of ethylene glycol / water mixed solvent with a volume ratio of 1:1, then added 800 mg of graphene powder, and the mixture was o After ultrasonic dispersion in a water bath of C for 10 minutes, slowly add dilute NaOH solution to the mixture to adjust the pH of the mixture to 8-9; then continue to ultrasonically disperse the mixture for 1 hour to form nickel ions uniformly dispersed in the graphene Dispersion on the surface.

[0032] (2) Heat the above dispersion system in a water bath to 40 o C. Slowly add 16 mL of 5% hydrazine hydrate aqueous solution under continuous stirring. After the addition, continue to stir for 6 hours, filter while hot, wash with water until neutral, and then wash with ethanol twice, the obtained black solid Immediately blow dry with nitrogen, then place in a vacuum oven, and dry at room temperature for 24 hours to obtain graphene-supported nickel nanoparticles.

[0033] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com