Processing method for protecting green color and crispiness of flexibly-packaged water celery

A processing method and technology of water celery, which is applied in the field of food preservation and processing, can solve problems such as changes in color and texture, and affect product quality, and achieve the effects of clear soup, expanded planting and operation scale, and bright green color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1: A soft-packaged water celery green preservation and crispness processing method, using fresh water celery as raw material, through pretreatment, blanching color protection, cooling, crispness preservation, auxiliary material conditioning, vacuum sealing, sterilization, cooling, and finally finished products , The steps are as follows:

[0022] (1) Raw material selection: Choose fresh, undamaged cress as raw material.

[0023] (2) Pretreatment: Cut off the roots and leaves, wash away the surface sediment and impurities with water, and cut into 2-3cm long sections.

[0024] (3) Blanching color protection: Put the water celery in Cu at 95℃ 2+ And Zn 2+ The concentration of the mixed solution is 200 / 50mg·kg -1 Blanch in the color protection solution for 2 minutes.

[0025] (4) Cooling: Cool with water at 15°C for 3 minutes.

[0026] (5) Keep crisp: After cooling, put the water celery in a certain concentration of 0.2% CaCl 2 Soak in the solution for 20 minutes, then rinse...

Embodiment 2

[0031] Example 2: The rest is the same as Example 1, except that in step (3), the cress is placed in Cu at 100°C. 2+ And Zn 2+ The concentration of the mixed solution is 200 / 50mg·kg -1 Blanch in the color protection solution for 2 minutes; in step (5), put the cooled water celery in a certain concentration of 0.3% CaCl 2 Soak in the solution for 20 minutes, then rinse and drain with water; in step (7), the vacuum-sealed cress is placed in a 100°C water bath for sterilization for 9 minutes.

Embodiment 3

[0032] Example 3: The rest is the same as Example 1, except that in step (3), the cress is placed in Cu at 100°C. 2+ And Zn 2+ The concentration of the mixed solution is 200 / 50mg·kg -1 Blanch in the color protection solution for 3 minutes; in step (5), the cooled water celery is placed in a certain concentration of 0.3% CaCl 2 Soak in the solution for 20 minutes, then rinse and drain; in step (6), mix the seasoning with water celery in a certain proportion, the seasoning includes salt, MSG, compound spices, vegetable oil, sesame oil and other seasonings, and then add 0.15% lemon Acid to pH 4.4, mix well, put it into a cooking bag, and vacuum seal; in step (7), the vacuum-sealed water celery is sterilized in a 100°C water bath for 10 minutes.

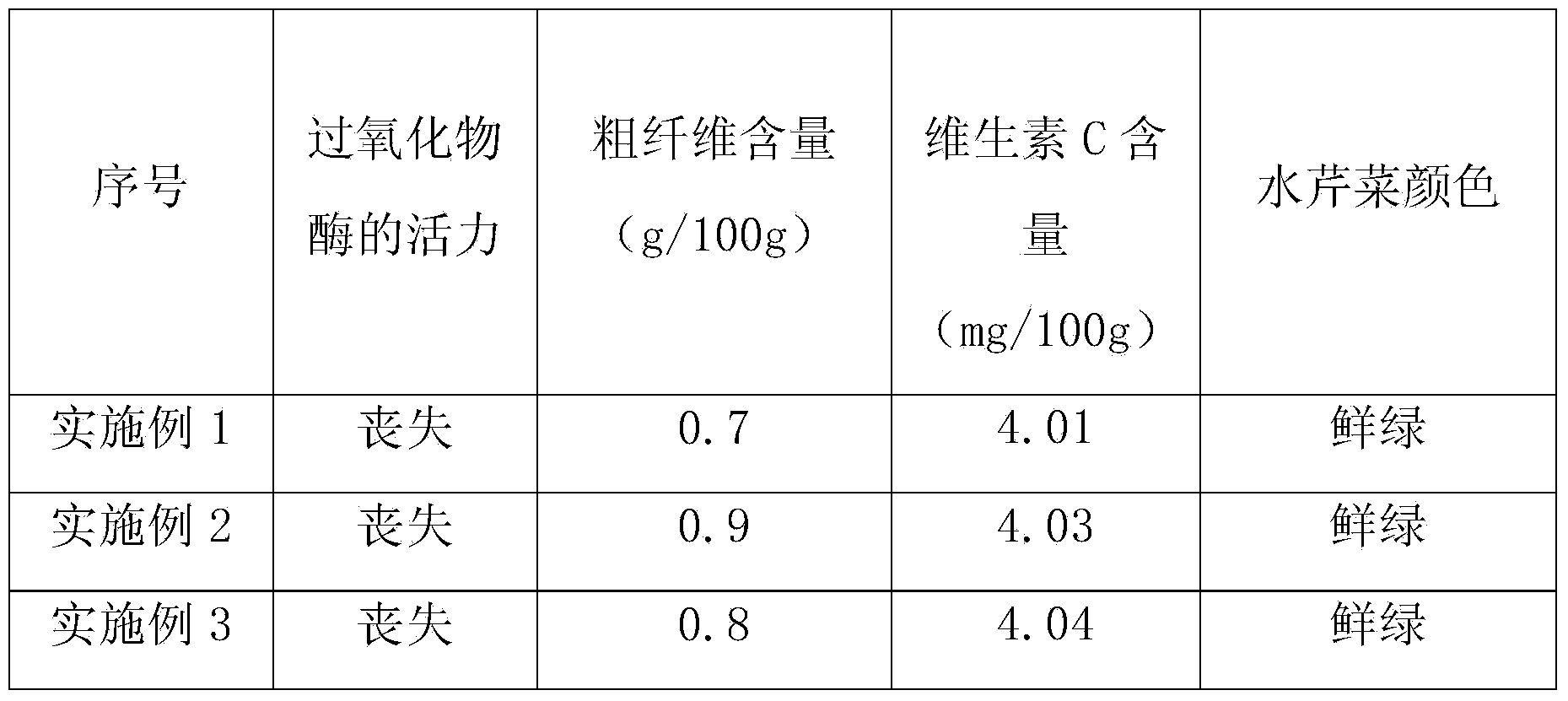

[0033] After the above steps, to be tested:

[0034]

[0035] Based on the above: the soft-packaged cress product produced by this method has bright green color, clear soup, stable storage, and the unique aroma and taste of cress. The crude fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com